fluorescent lamp

A technology for fluorescent lamps and lamp tubes, which is applied to light sources, light source fixing, semiconductor devices of light-emitting elements, etc., can solve the problems of high cost, complex structure, and difficulty in adding fixed structures, and achieves low production cost, simple overall structure, and easy assembly. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

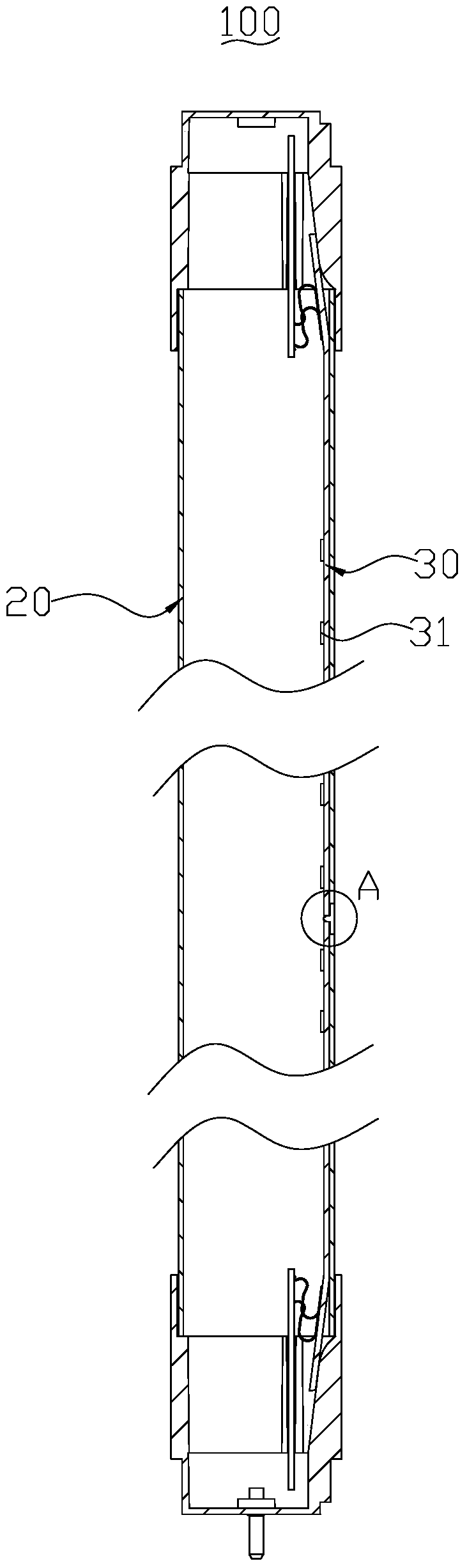

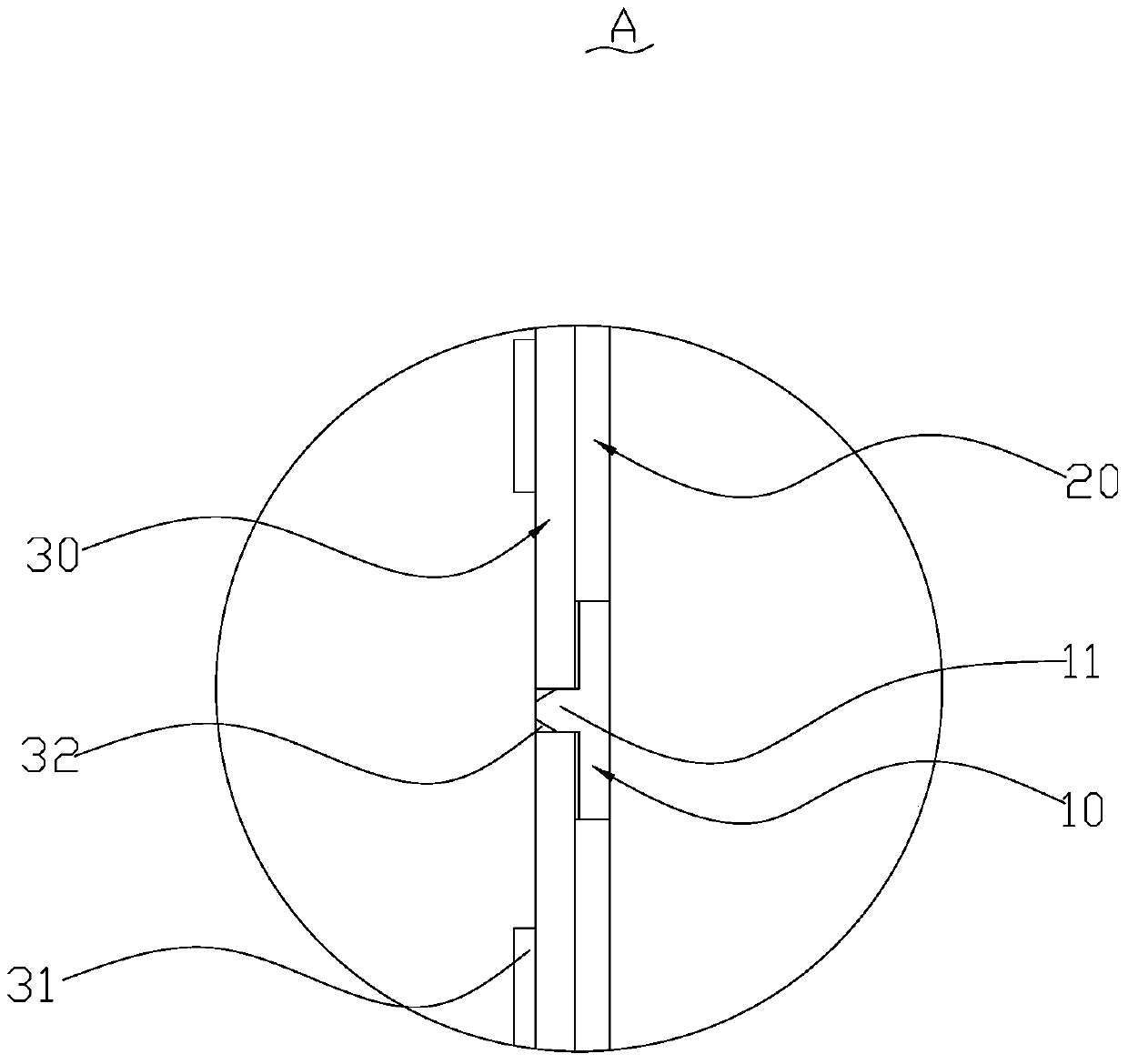

[0009] For the fluorescent lamp 100 of the first embodiment of the present invention, please refer to Figure 1 to Figure 2 .

[0010] Please refer to figure 1 with figure 2 , the fluorescent lamp 100 includes a lamp tube 20 , a light source board 30 and a hot melt adhesive block 10 . The light source board 30 is accommodated in the lamp tube 20, the hot melt adhesive block 10 is fixed on the light source board 30 and is located between the light source board 30 and the inner wall of the lamp tube 20, and the lamp tube 20 is heated to make the hot melt The glue block 10 is melted, and after cooling, the melted hot melt glue block 10 sticks the light source plate 30 on the inner wall of the lamp tube 20 . The lamp tube 20 is made of glass material. The inner wall of the lamp tube 20 is coated with a fluorescent powder layer or a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com