Novel dry type ground heating system

A dry, floor heating technology, applied in hot water central heating systems, heating systems, heating methods, etc., can solve the problems of difficult maintenance, uneven heat conduction, and high floor height of wet floor heating, so as to improve the heating effect and increase the temperature. The effect of shortened time and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The "horizontal" and "vertical" mentioned in this application are only used to cooperate with the content disclosed in the specification for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention. Therefore, there is no technical The substantive meaning of , and the change or adjustment of its relative relationship, without substantial change in technical content, should also be regarded as the scope of implementation of the present invention.

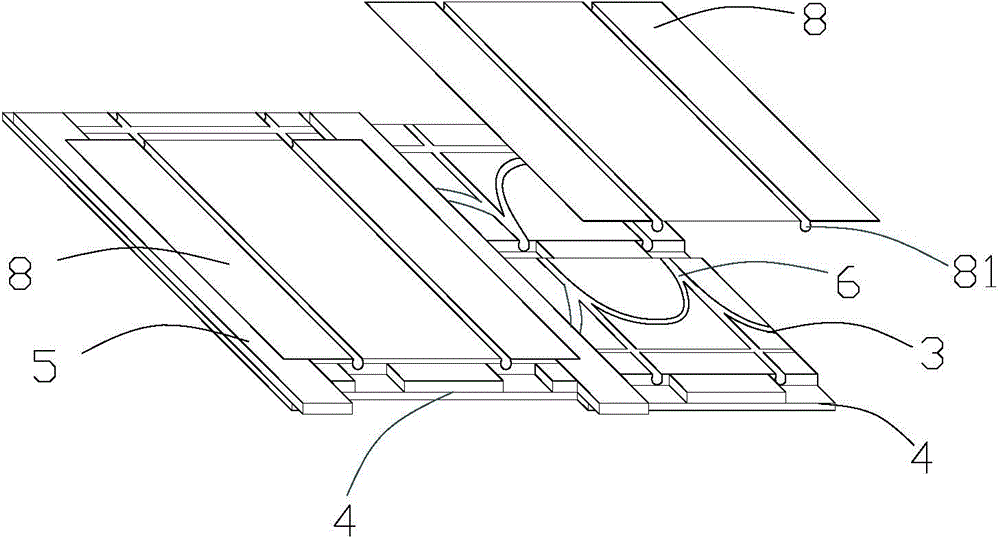

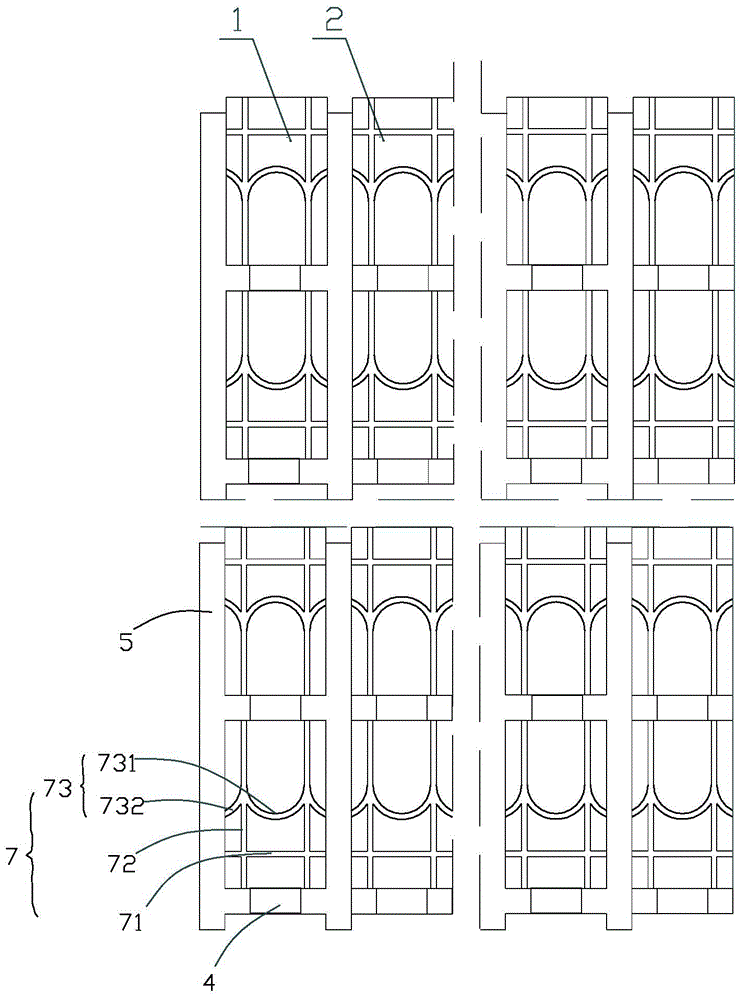

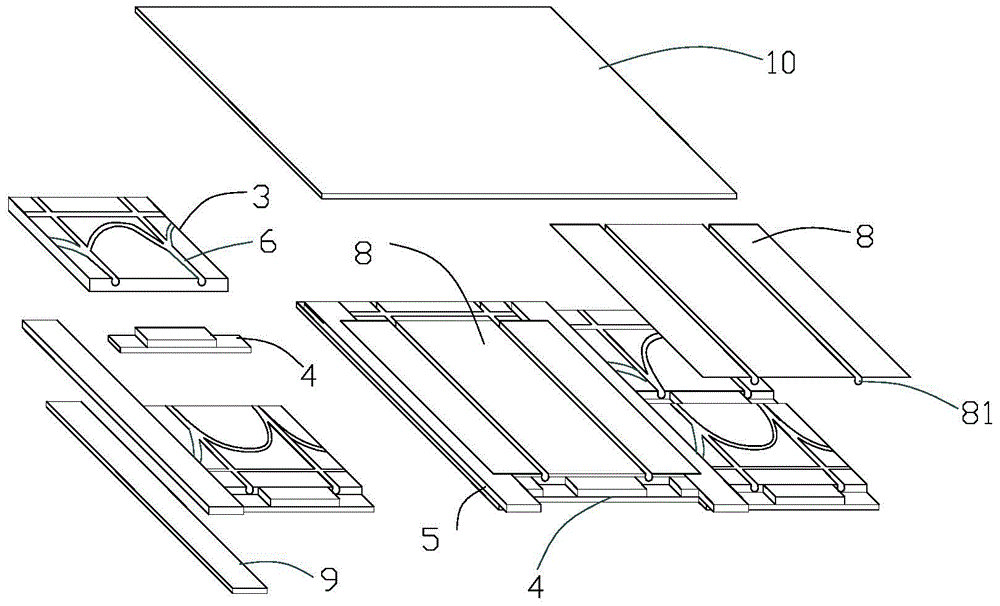

[0028] Such as Figure 1-4 Shown is the novel dry floor heating system of the present invention, which includes a first unit 1 and a second unit 2 . The first unit 1 includes two insulating extruded boards 3 of the same shape, two transverse reinforcements 4 and two longitudinal fixings 5 . A transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com