Magnetic micro-displacement platform type ladder angle mirror laser interferometer, calibration method and measurement method

A corner mirror, interferometric measurement technology, applied in measurement devices, instruments, optical devices, etc., can solve problems such as poor anti-environmental interference ability, and achieve the effect of improving accuracy and improving movement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

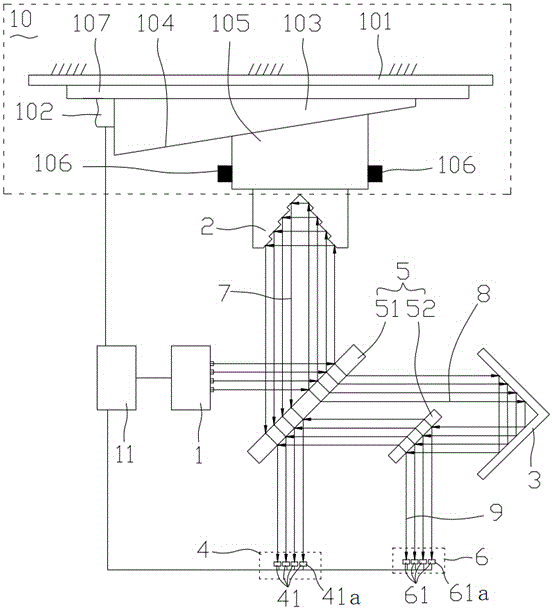

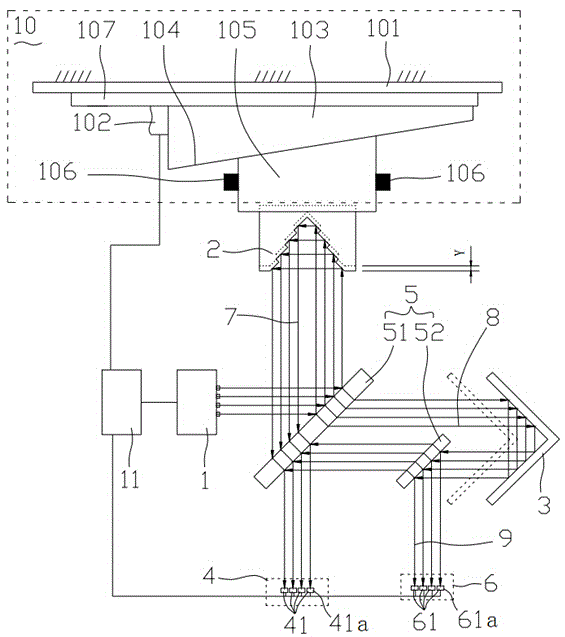

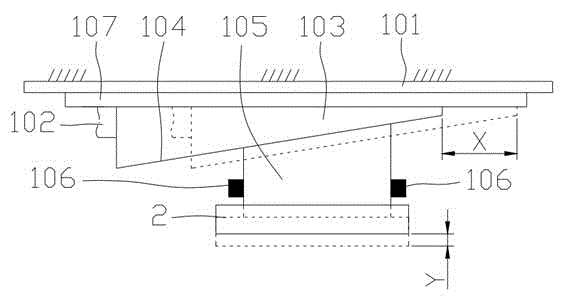

[0051]Embodiment 1, as shown in the figure, a magnetic micro-displacement platform-type step-angle reflector laser interferometer, including a laser source 1, a micro-moving step-angle reflector 2, an interferometric photodetector group 4, and a moving angle reflector 3. The beam splitter group 5 and the magnetic micro-displacement platform 10, the micro-movement stepped angle reflector 2 is arranged on the magnetic micro-displacement platform 10, and the laser source 1 emits a z-beam laser beam to the beam splitter group 5 , wherein z is a positive integer greater than or equal to 2, the interferometric photodetector group 4 includes z interferometric photodetectors, each interferometric photodetector 41 corresponds to a laser beam, and each laser beam After passing through the beam splitter group 5, it is divided into a first laser beam group 7 and a second laser beam group 8, and the first laser beam group 7 shoots to the micro-movement step angle reflector 2, and passes thr...

Embodiment 2

[0061] Embodiment 2, as shown in the figure, a calibration method for a magnetic micro-displacement platform-type step-angle mirror laser interferometer, including the following steps:

[0062] Step 1. Position adjustment: adjust the laser source 1, the micro-movement stepped angle mirror 2, the beam splitter group 5, the interferometric photodetector group 4, the reflection measurement photodetector group 6, the moving angle mirror 3 and the magnetic micro-displacement the location of platform 10;

[0063] Step 2, adjust the optical path: start the laser source 1, further finely adjust the micro-movement stepped angle reflector 2, the beam splitter group 5, the interferometric photodetector group 4, the reflection measurement photodetector group 6, and the moving angle reflector 3 and the position of the magnetic micro-displacement platform 10, so that the optical path of the laser interferometer meets the design requirements;

[0064] Step 3, generate the strongest interfer...

Embodiment 3

[0072] Embodiment 3, as shown in the figure, a measurement method using a magnetic micro-displacement platform-type step-angle mirror laser interferometer and a calibration method:

[0073] In the actual measurement environment, it is assumed that the signal reading measured by the calibration reflectance measurement photodetector 61a is x, the signal reading obtained by the calibration interferometric photodetector 41a is y, and the x value and the y value are at the strongest Comparisons are made in the interference database, the weakest interference database, and the 1 / n wavelength interference database. When the x value and y value match a certain set of values in the strongest interference database, this position is considered to be the strongest constructive interference position , when the x value and y value match a set of values in the weakest interference database, this position is considered as the weakest destructive interference position, when the x value and y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com