Field-operation optical cable

A field optical cable and optical fiber technology, applied in the field of optical cable, can solve the problems of the optical cable being unable to guarantee the service life, losing the communication function, delaying the acquisition of real-time information, etc., achieving good tensile strain capacity, avoiding compression damage, and maximizing the buffer effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

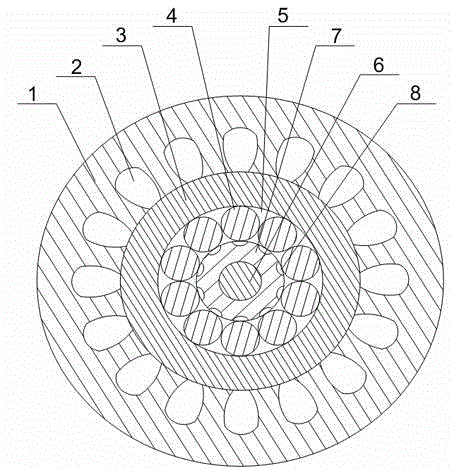

[0020] Such as figure 1 As shown, this embodiment includes a casing 3, and a polyurethane sheath 1 is sheathed on the outer wall of the casing 3, and a plurality of buffer grooves 2 are opened on the inner wall of the polyurethane sheath 1 along its axial direction, so that The two side walls of the buffer groove 2 are bent away from its center, the bottom of the buffer groove 2 expands outward along the radial direction of the polyurethane sheath 1, and a plurality of optical fibers 4 are arranged inside the casing 3, and a plurality of The optical fiber 4 is helically twisted on the aramid fiber tube 7 located in the middle of the sleeve 3, and the fiber paste 5 is filled between the sleeve 3 and the aramid fiber tube 7, and the aramid fiber The outer wall of the tube 7 is also provided with a plurality of spiral grooves 8 with arc-shaped cross-sections corresponding to the optical fibers 4 ; it also includes an FRP reinforcement 6 , and the FRP reinforcement 6 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com