Method for monitoring faults in smelting process of multimode magnesia electrical smelting furnace

A fused magnesium furnace, fault monitoring technology, applied in the direction of electrical testing/monitoring, electrical digital data processing, special data processing applications, etc., can solve problems such as frequent faults, affecting product output and quality, abnormal furnace temperature, etc., to reduce False positives and negative negatives, the effect of improving monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

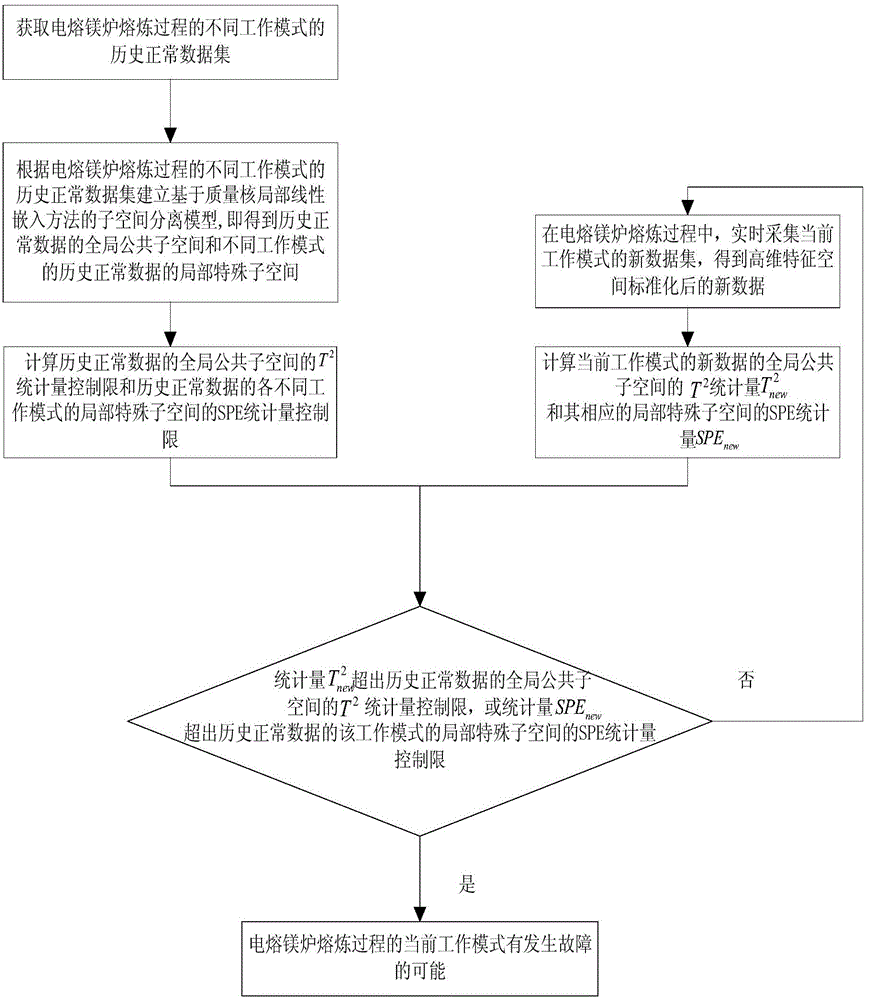

[0046] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0047] The main raw material for smelting magnesite furnaces in my country is magnesite ore, and its raw material composition is magnesium oxide. The smelting process of the electric fused magnesium furnace goes through the process stages of melting, separation, purification and crystallization. Due to the difference in the amount of impurities contained in the ore, the physical and chemical properties of the clinker are different. Different magnesite raw materials and different feeding operations correspond to the characteristics of the smelting process of the capacitor magnesium furnace, and the process data has strong nonlinearity.

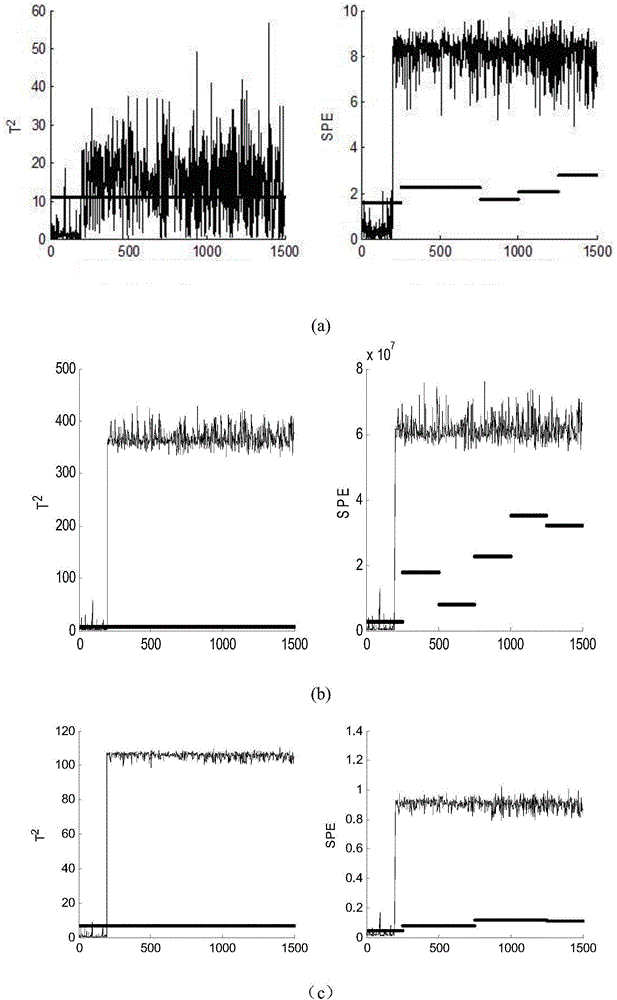

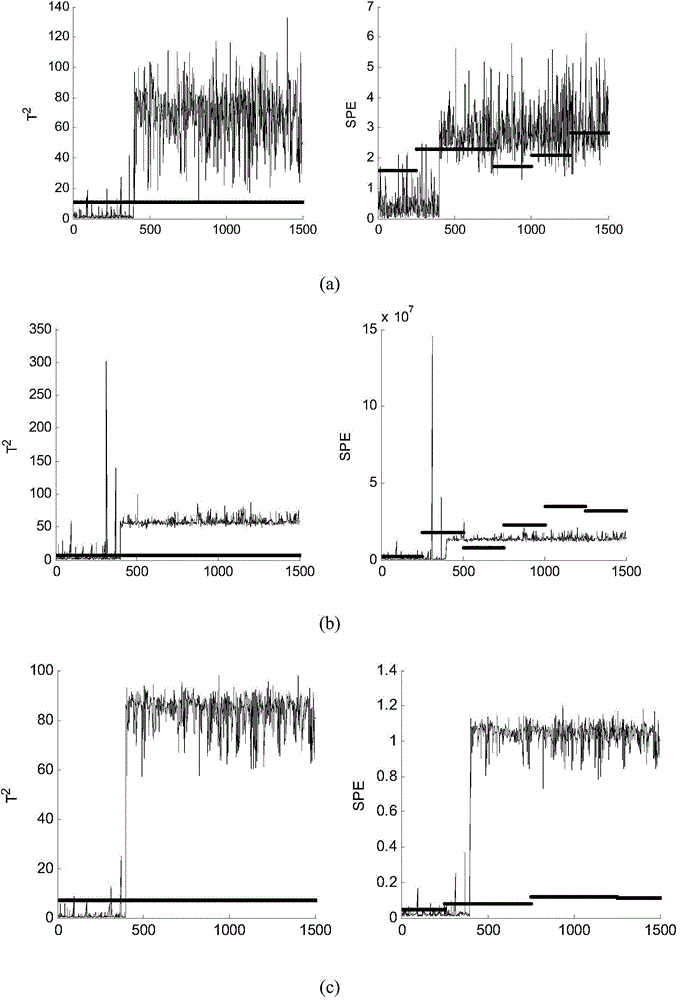

[0048] In this embodiment, the process data obtained in the two cases of raw material massive magnesite, block powder mixed magnesite and powdery magnesite with and without feeding are selected as six diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com