Enameled assembly transposition conducting wire

A technology of transposition conductors and transposition wires, which is applied in the direction of conductors, insulated conductors, insulated cables, etc., and can solve problems such as insulation damage of enamelled copper flat wires, shortening the length of transposition cycles, and movement of enamelled copper flat wires, etc. To achieve the effect of ensuring product quality and safety, shortening the complete transposition cycle, and reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

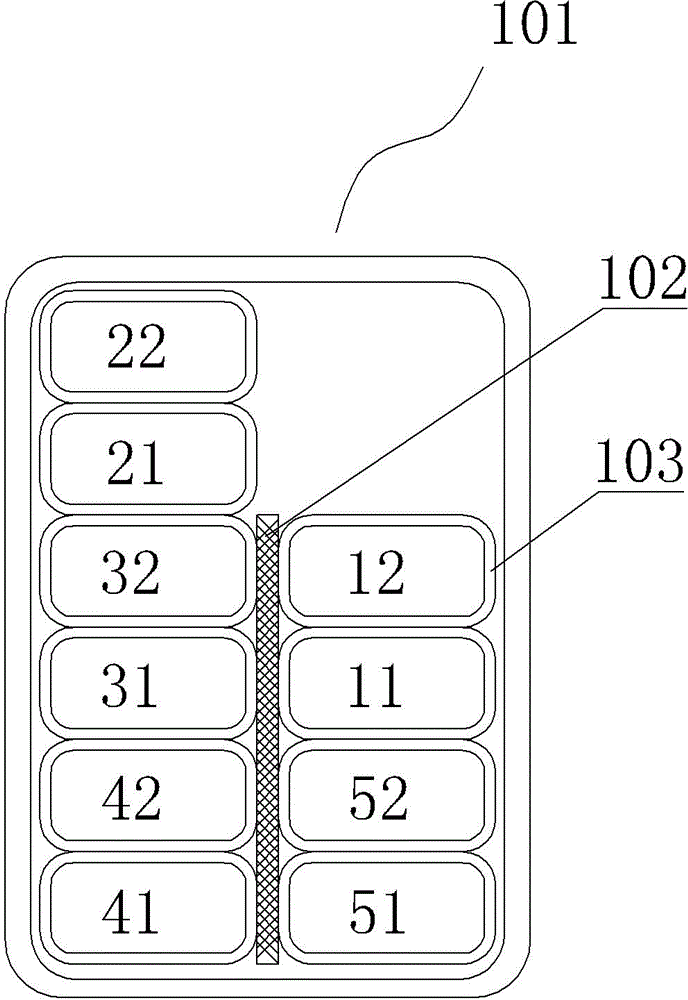

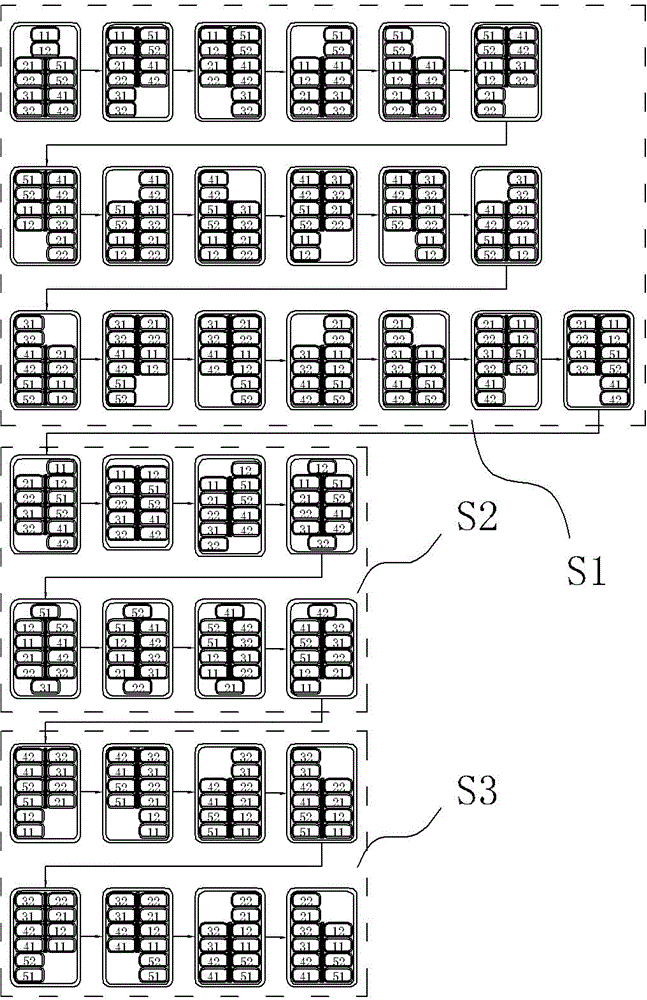

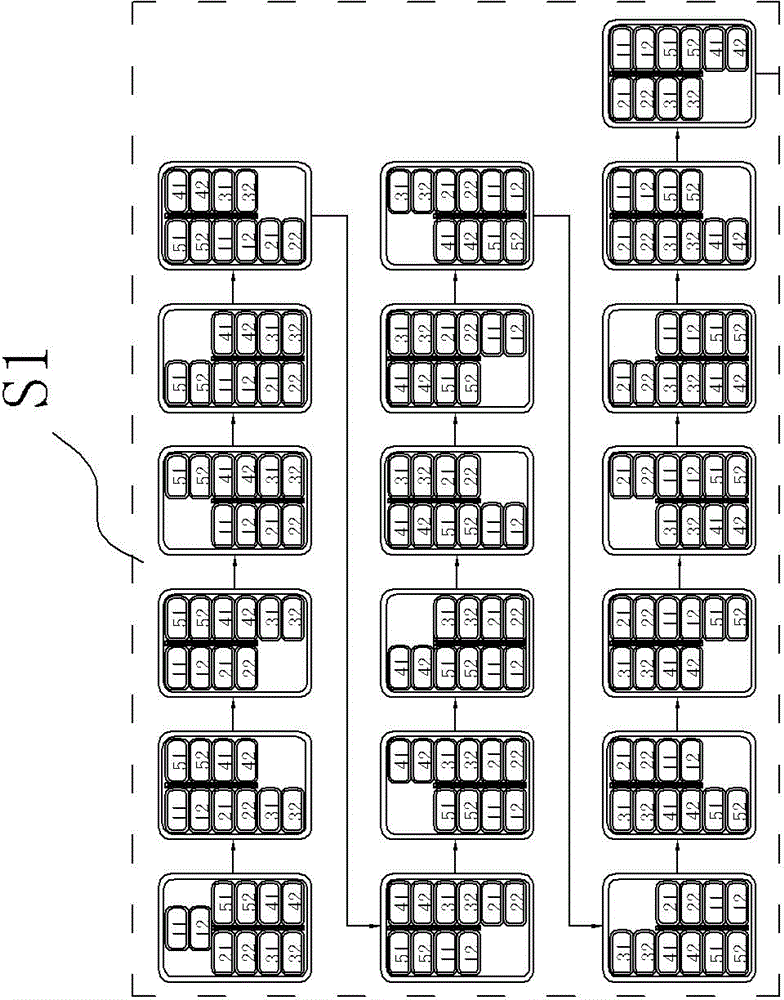

[0014] Such as figure 1 , figure 2 , Figure 2-1 to Figure 2-3 As shown, the enamelled composite transposed wire 101 includes several transposed wire cores, figure 1 Among them, 11, 12, 21, 22, 31, 32, 41, 42, 51, and 52 are all transposition cores, and the transposition cores are composed of an even number of enamelled copper flat wires superimposed on each other according to the wide surface. Two rows, two enamelled copper flat wires adjacent to each other up and down constitute a group, and each group of enamelled copper flat wires performs a circular transposition in the same direction along the narrow surface in sequence, as shown in diagram 2-1 As shown, enamelled copper flat wires 11 and 12 form a group, enameled copper flat wire 11 is superimposed on enamelled copper flat wire 12, enamelled copper flat wires 21 and 22 form a group, enameled copper flat wire 21 is superimposed Above the enamelled copper flat wire 22, the enamelled copper flat wires 31 and 32 form a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap