Port injection system for reduction of particulates from turbocharged direct injection gasoline engines

A technology of air inlet injection and turbocharging, which is applied to engine components, combustion engines, engine ignition, etc., can solve the problems of increasing turbocharged engine particle emissions, poor fuel mixing, etc., and achieve the effect of reducing particle emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

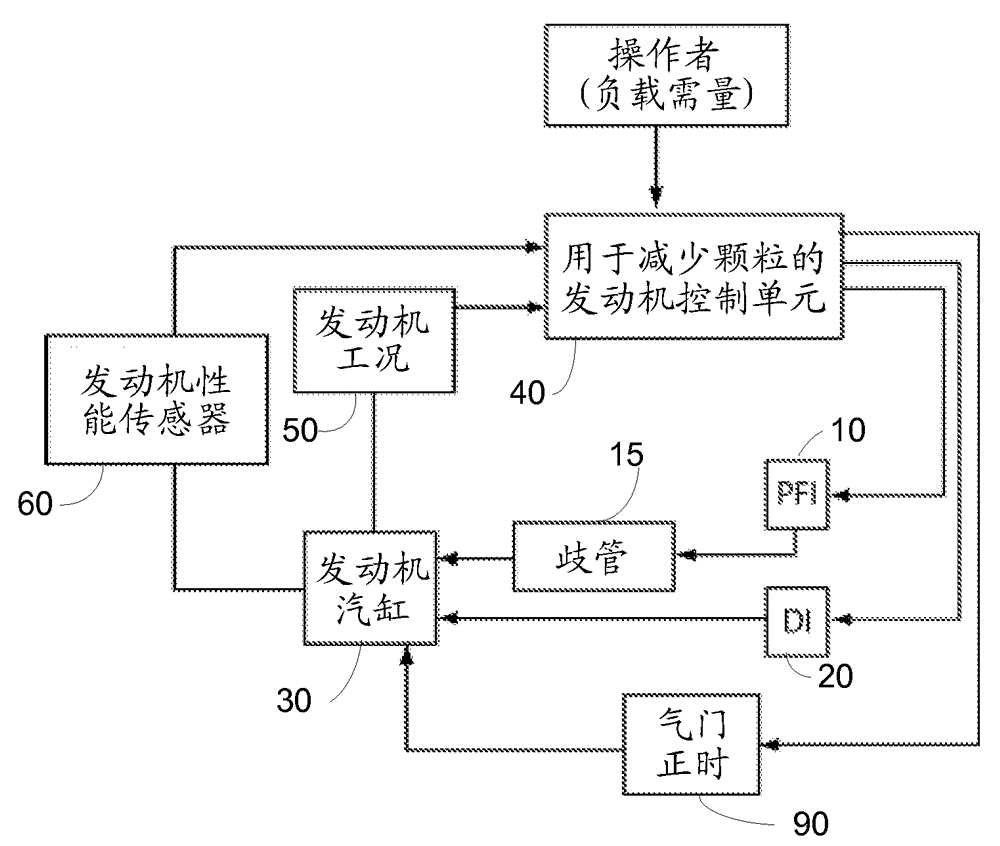

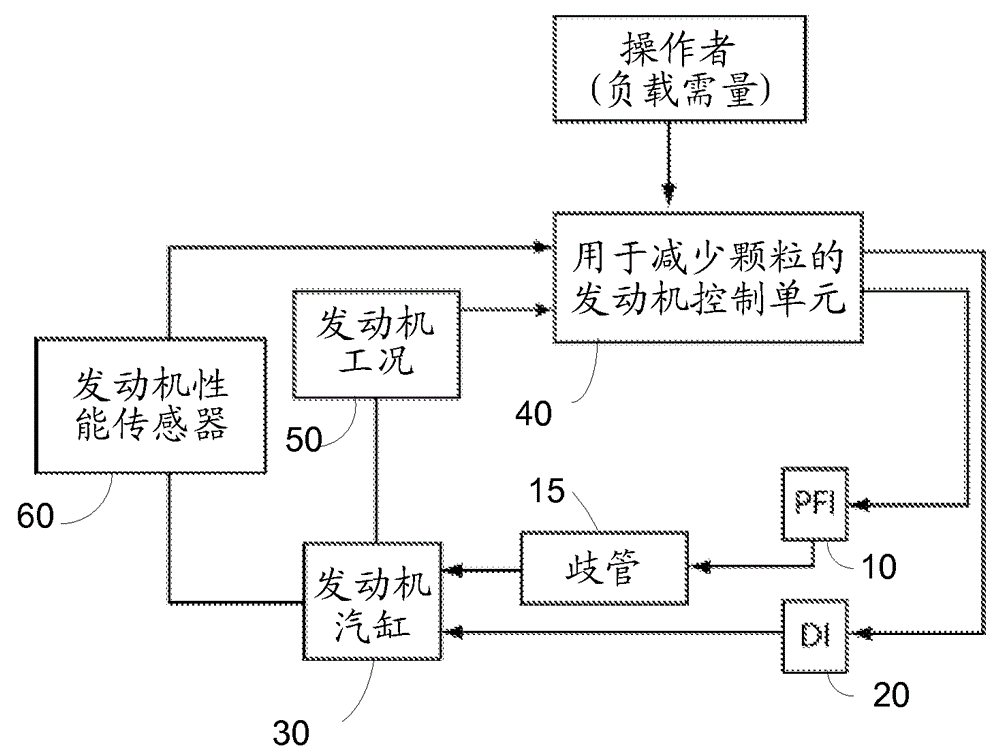

[0013] As described above, the present invention monitors and regulates engine operation using an engine control system to maximize engine performance and efficiency and minimize particulate emissions. The engine control system can affect the composition of the fuel introduced through the use of PFI and DI based on engine operating conditions, particulate emissions, and other factors.

[0014] Closed loop control, open loop control, or a combination of open loop and closed loop may be used to optimize particle emission reduction while providing the desired amount of knock control. Various embodiments of these control systems are shown in the drawings.

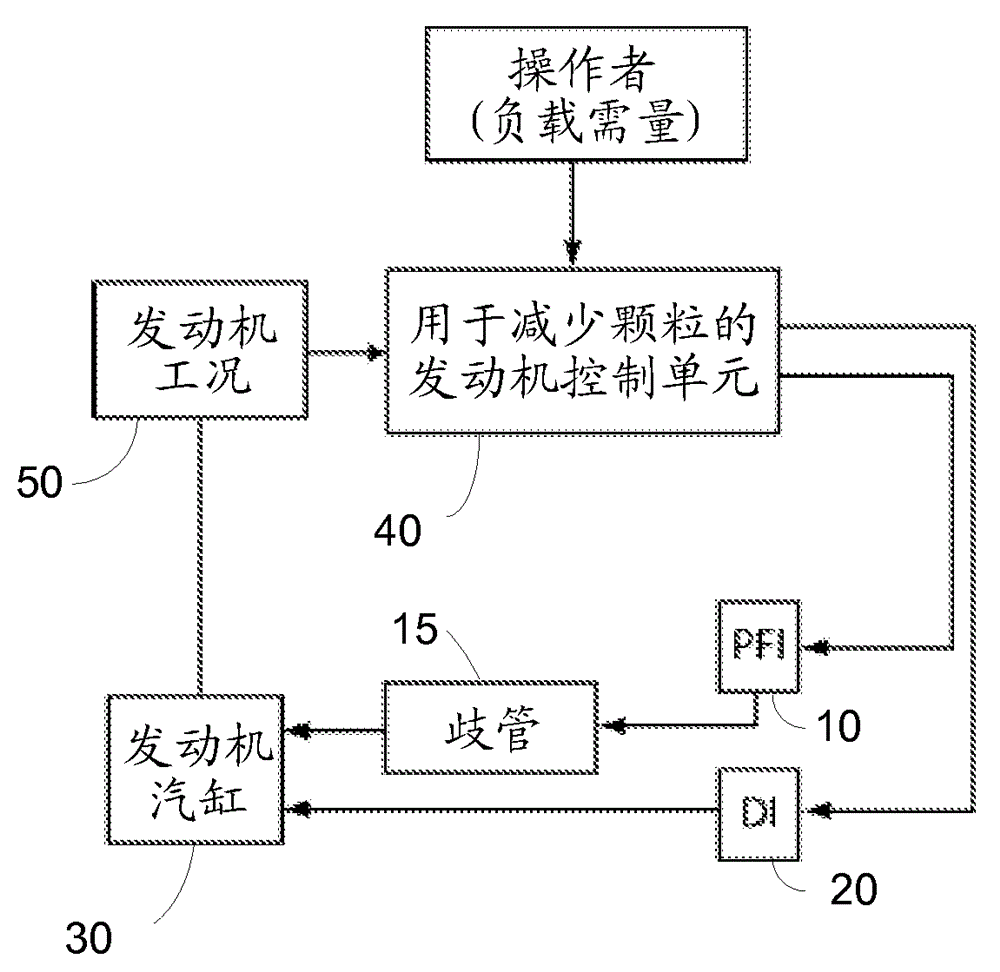

[0015] figure 1 A schematic diagram showing an engine system with two sets of injectors, namely, port fuel injectors 10, which introduce fuel into an area outside the cylinders, such as a manifold 15, for each cylinder There is a port fuel injector 10; and direct injectors 20 which introduce fuel as a liquid directly into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com