Heat exchanger and method for manufacturing same

A technology for heat exchangers and manufacturing methods, which is applied in the fields of heat exchanger fixation, heat exchange equipment, semiconductor/solid-state device manufacturing, etc. It can solve problems such as reliability difficulties and difficult-to-perfect proposals, and achieve low cost and reliability Improvement, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

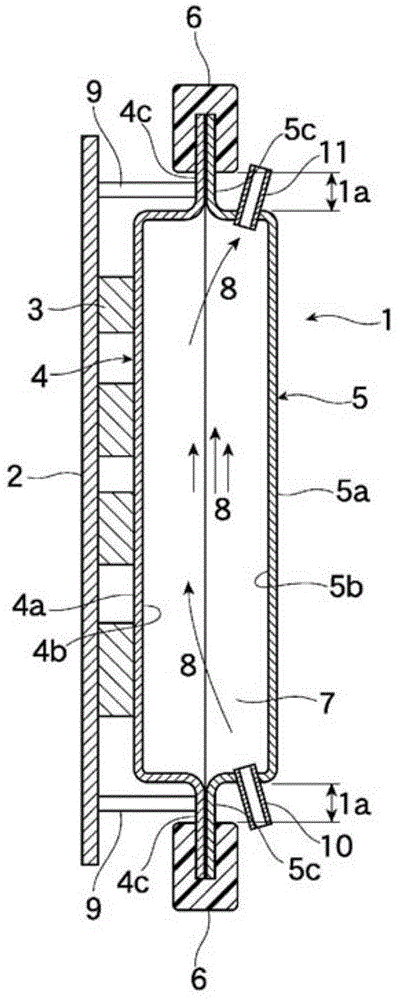

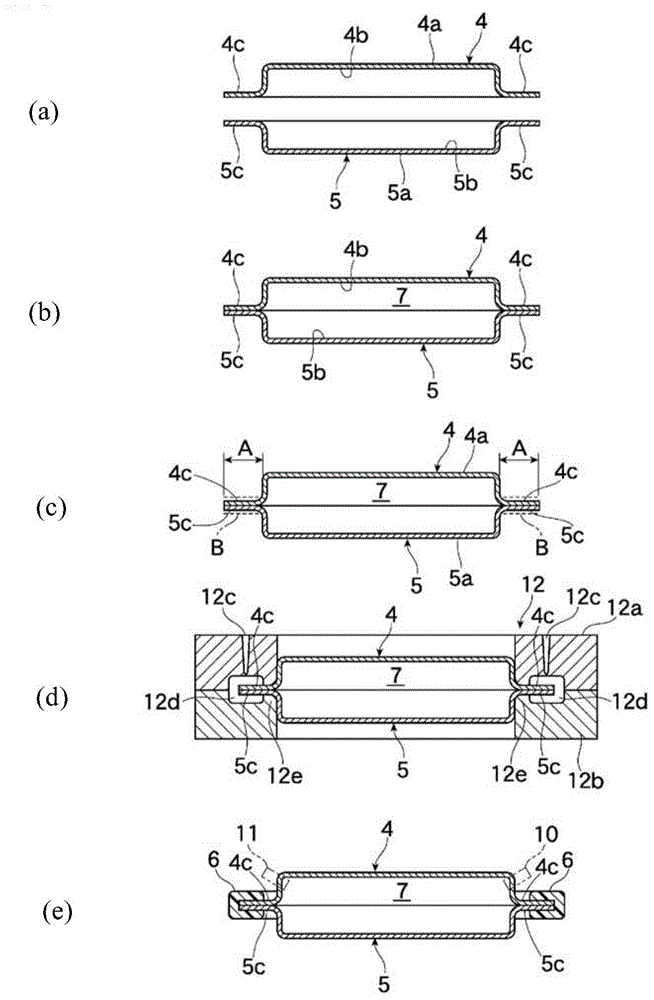

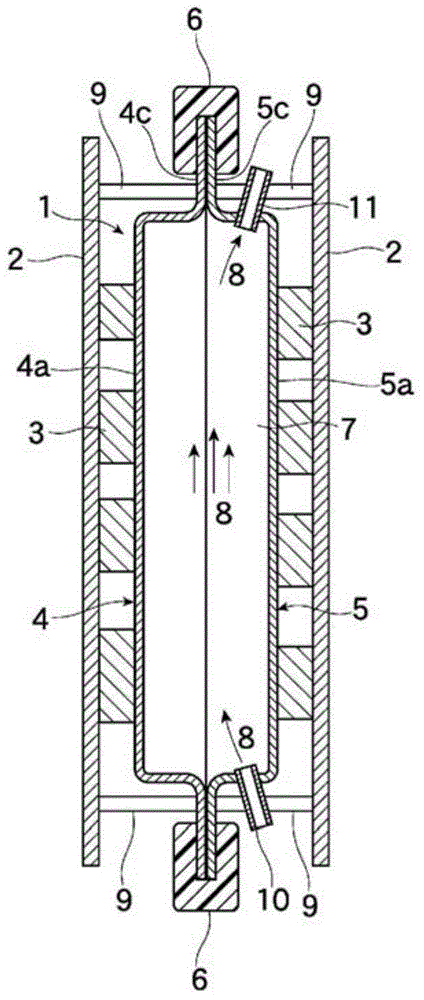

[0074] Next, embodiments of the present invention will be described based on the drawings. figure 1 The structure of is a cross-sectional view of the basic form of the heat exchanger of the present invention, and shows a state in which it is in contact with electronic components. The heat exchange device can be applied to heating and cooling, but in this embodiment, it will be described as a heat exchanger applied to cooling. The heat exchanger 1 for cooling (hereinafter referred to as "heat exchanger 1") exchanges heat with electronic components such as semiconductors ( The heat exchange objects) 3 are placed in contact with each other. The electronic component 3 to be cooled is mainly used in a control circuit device of an automobile.

[0075] The electronic component 3 becomes a heat source, and since the function as an electronic component will be impaired if the temperature exceeds the limit, cooling is required. The heat exchanger 1 of the present embodiment has a str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com