Tea leaf sorter

A classifier and tea technology, applied in the direction of solid separation, separation of solids from solids by air flow, and sieving, etc., can solve the problems of insufficient sorting, single function, high manufacturing cost, and achieve remarkable and convenient vibration effect. The effect of using and not taking up space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

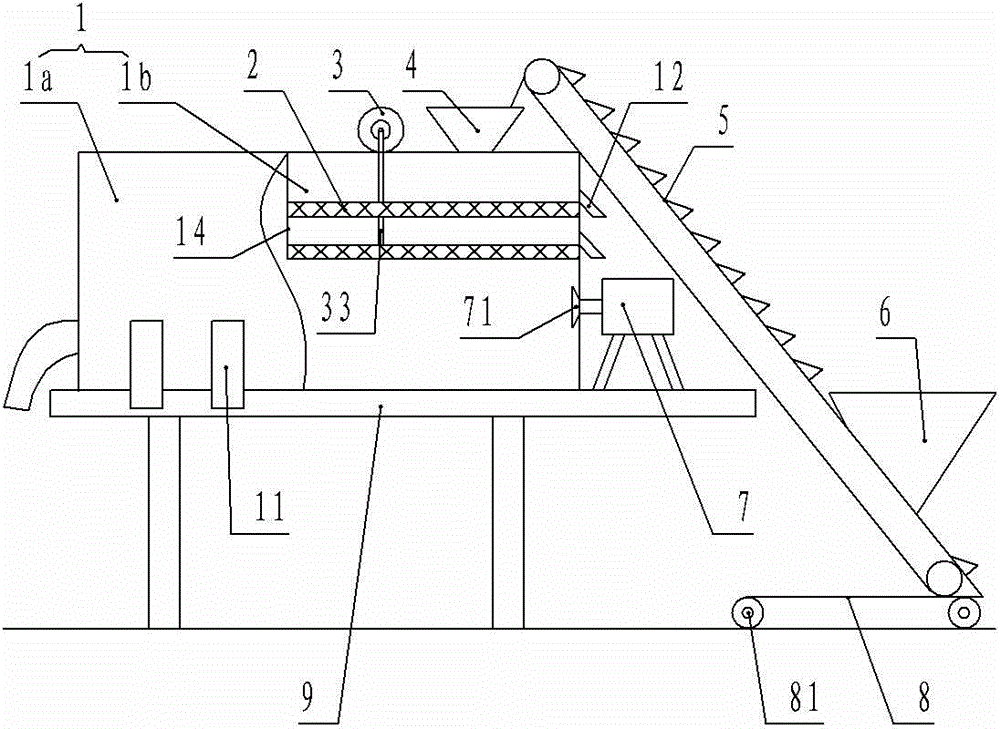

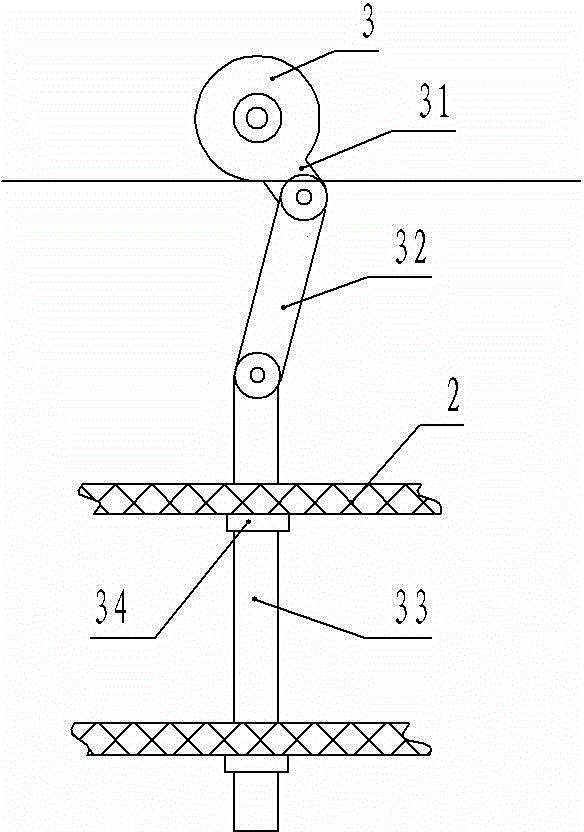

[0014] figure 1 The shown tea classifier includes a frame 9 and a box body 1 arranged on the frame 9. The box body 1 is divided into a screening chamber 1b and a winnowing room 1a through a partition 14, corresponding to the box body above the screening room 1b. 1 is provided with a feed hopper 4 and a motor 3, and two layers of screens 2 are provided in the screening room 1b, such as figure 2 As shown, the output shaft of the motor is sleeved with a rotating wheel 3, and the rotating wheel 3 has a radially protruding protrusion 31, and a connecting rod 32 is hinged between the protrusion 31 and the vibrating rod 33, and the vibrating rod 33 passes through each A seal 34 is arranged between the vibrating rod 33 and each layer of screen 2, and the vibrating rod 33 is fixedly connected to each layer of screen 2 through the seal 34 of each layer; the ape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com