Automatic clamping and water retaining device for cutting machining

A technology of automatic clamping and water blocking device, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of high cost, splashing cutting fluid, affecting workpiece loading and unloading, etc., to ensure accuracy and precision. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

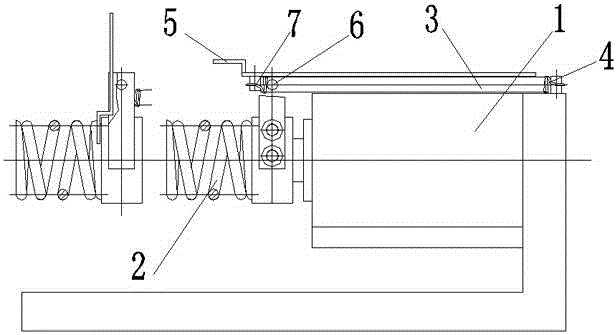

[0014] The present invention includes a cylinder 1. One end of the cylinder 1 is provided with a clamping block 2 that moves with the cylinder 1; the upper part of the cylinder 1 is provided with a water baffle 3 that follows the cylinder 1, and one end of the water baffle 3 passes through a spring A 4 is connected to the cylinder 1, the front end of the water baffle 3 is provided with a positioning plate 5 that restricts the movement of the water baffle 3, the front end of the water baffle 3 is provided with a rotating shaft 6, and the positioning plate 5 is provided with the rotating shaft 6 The corresponding spring two 7.

[0015] The clamping plate 3 is a clamping spring.

[0016] The clamping spring is sleeved on the shaft, so that the movement of the clamping spring is guided by the shaft.

[0017] The first spring 4, the second spring 7, and the water baffle 3 are arranged coaxially.

[0018] The working process of the present invention is: when the device is working, the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com