A multifunctional engineering attachment of a six-bar mechanism

A six-bar mechanism and multi-functional technology, applied in the field of mechanical design, hydraulic control, earthquake resistance and disaster reduction, can solve the problems of high cost, difficult manufacturing, inconvenient operation, etc., and achieve the goal of increasing the opening size, increasing the clamping function, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

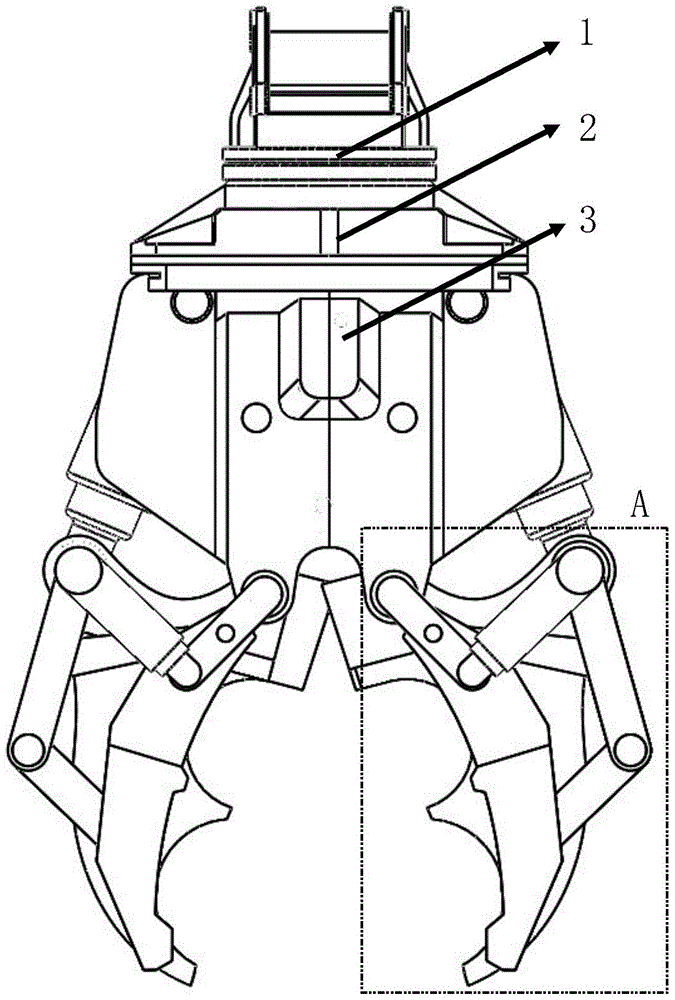

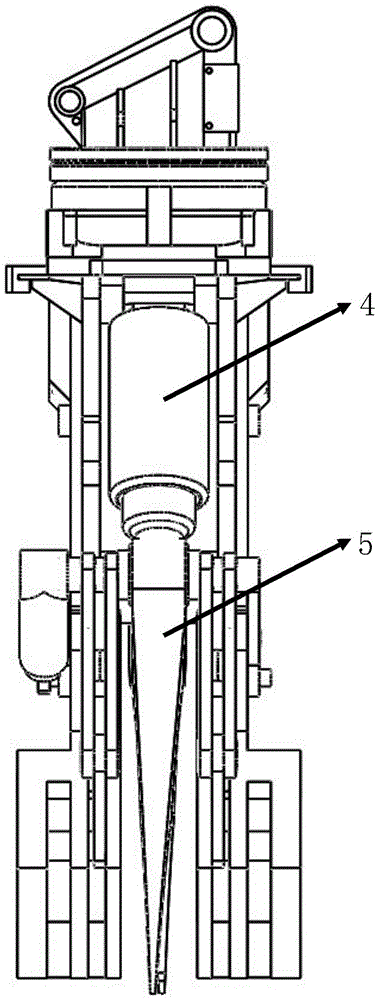

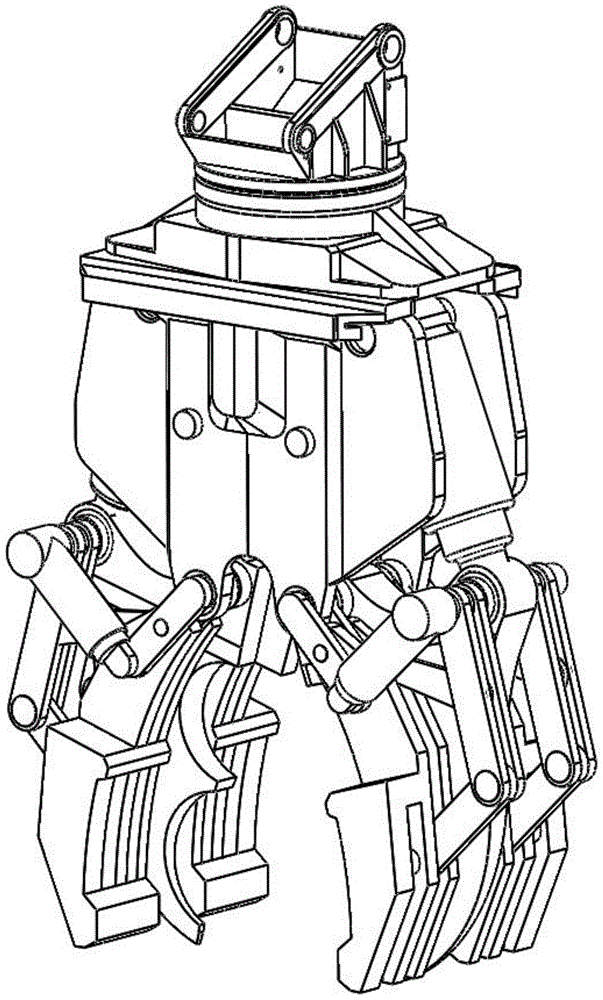

[0034] Such as figure 1 , Figure 6 , Figure 7 as well as Figure 12 , a multifunctional engineering attachment of a six-bar mechanism is composed of a six-link clamping device (A), a scissor separating device (B), a shearing device (C), and a locking device (D). Such as figure 1 As shown, the multifunctional attachment is in the working state of shearing and crushing. At this time, the positioning block (7) on the attachment bracket (3) is inserted into the positioning groove (6), the scissors separation device (B) is in the closed state, and the attachment bracket (3) and the attachment base (2 ) is relatively fixed. The six-link clamping device (A) is in the retracted state, and the swing hydraulic cylinder (19) is locked to keep the position of the clamping hand (15) to prevent it from interfering with the work of the hydraulic scissors (5). Drive the hydraulic cylinder (4) as the main power source to push the hydraulic scissors (5) to rotate, the hydraulic scissor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com