Motor braking device of electric bicycle back-pedal brake mechanism

A technology of electric bicycles and brake mechanisms, applied in the direction of bicycle brakes, bicycle accessories, vehicle parts, etc., can solve problems such as increasing production costs, increasing assembly processes, and reducing equipment reliability, so as to simplify assembly processes, improve safety, and respond fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

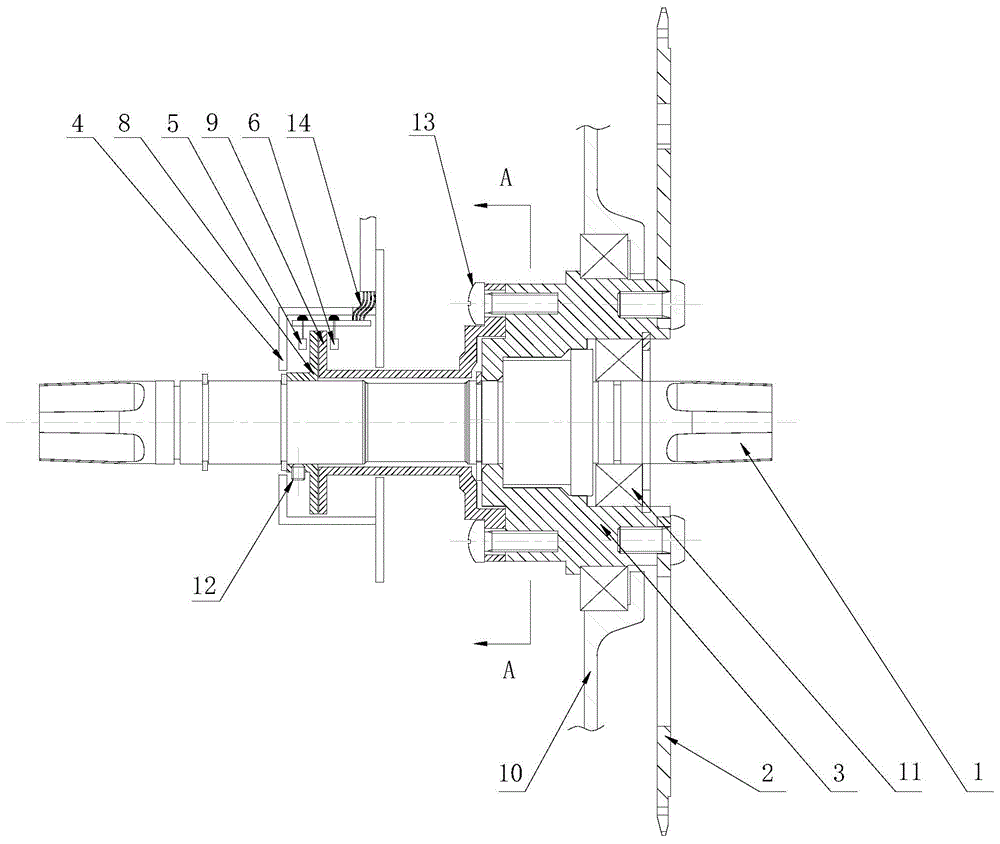

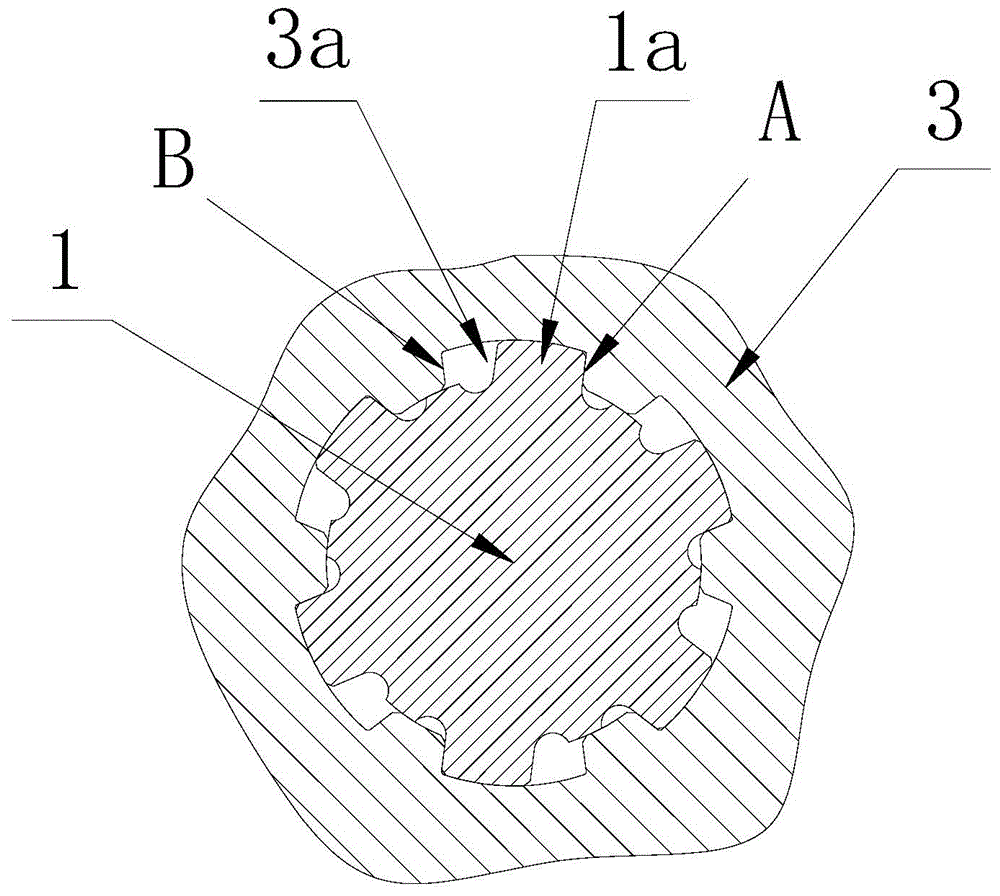

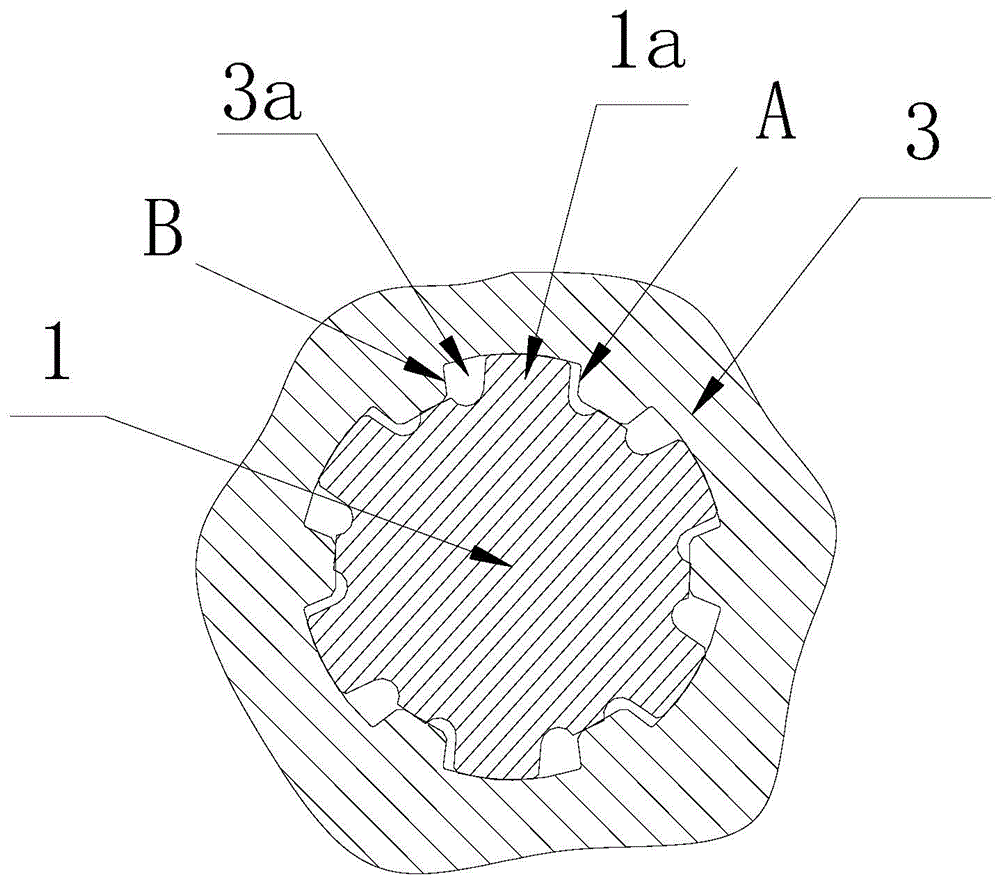

[0037] Example: Combine Figure 1~Figure 7 As shown, the specific implementation of the motor brake device of the electric bicycle reverse pedal brake mechanism of the present invention will be described. This embodiment is specifically assembled on an electric bicycle that adopts a central motor, such as figure 1 As mentioned above, its conventional structure is: vehicle frame (not shown in the figure), central shaft 1 installed on the vehicle frame and central motor (omitted in the figure), as in the prior art, the central motor and central shaft 1 are connected and transmitted through a gear reduction mechanism, and the housing 10 of the central motor is fixed to the vehicle frame; a chain disc 2 is also arranged on the central shaft 1, and the chain disc 2 is connected to the brake mechanism installed on the wheel hub through a chain (in the figure omitted) connected. The core improvement of the present invention is as follows:

[0038] The chain disc 2 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com