Preparation method of concrete insulation board

A thermal insulation board and concrete technology, which is applied in the field of preparation of concrete thermal insulation boards, can solve problems such as poor fire performance, and achieve the effects of low cost, light weight, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

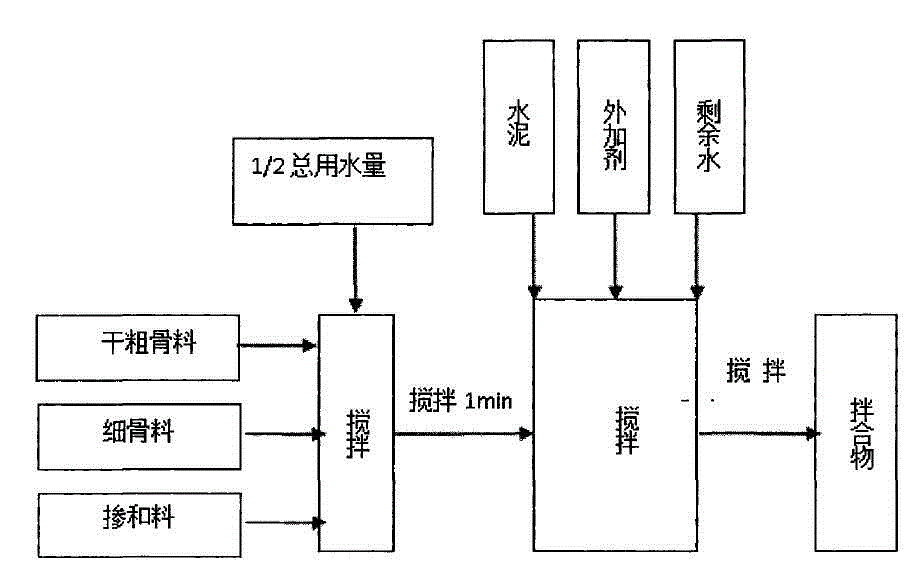

[0015] refer to figure 1 As shown, a method for preparing a concrete insulation board of the present invention includes expanded perlite particles, pottery sand, P.C42.5 composite laurate cement, urban tap water and polycarboxylate high-performance water reducer, and the specific ratio is expansion Perlite particles 45.2Kg / m 3 , pottery sand 533.9Kg / m 3 , P.C42.5 composite laurate cement 370Kg / m 3 ,City tap water 229Kg / m 3 ,Polycarboxylate high performance water reducer 851g / m 3 .

[0016] The sand rate of pottery sand is 0.6.

[0017] The insulation board also includes 1.5m of lightweight aggregate 3 .

[0018] The bulk density of expanded perlite particles is 78Kg / m 3 , the particle size is less than 3mm.

[0019] The particle size of pottery sand is less than 5mm.

[0020] A method for preparing a concrete insulation board. The preparation method is to add expanded perlite particles, pottery sand and light aggregate in the proportion of amine components, perform d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com