Copper-iron intermediate alloy and preparation method and application thereof

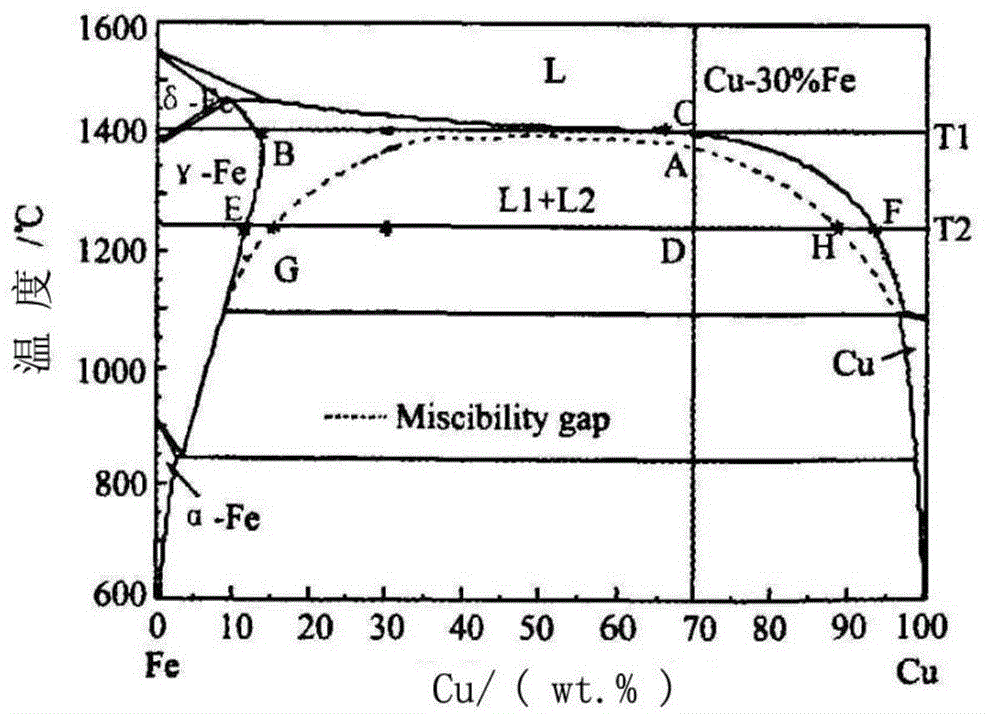

An intermediate alloy, copper-iron technology, applied in the field of non-ferrous metal alloys, can solve the problems of limiting the application research of Cu-Fe alloys, low solid solubility, etc., and achieve the effects of refined grains, stable chemical composition, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

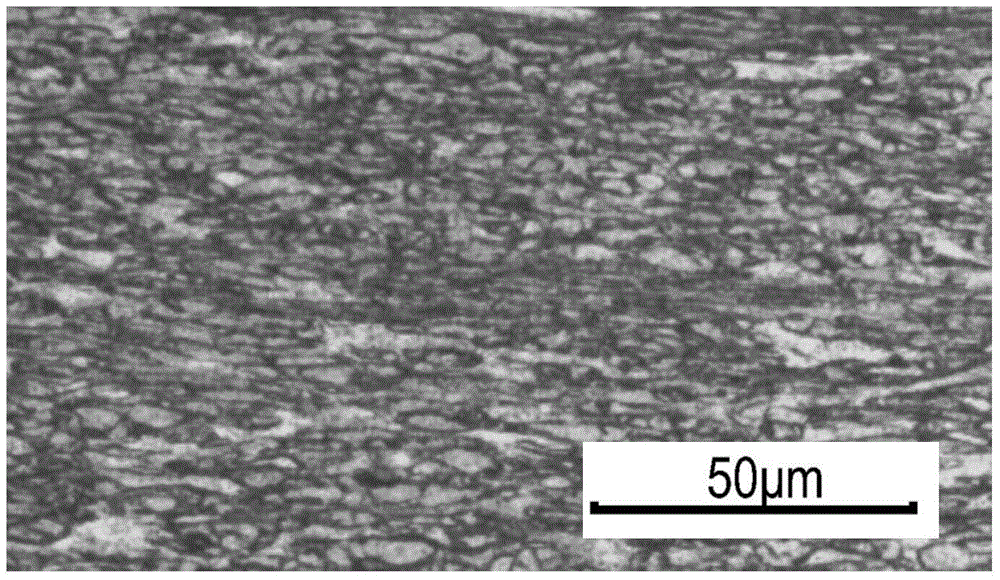

[0072] 1. The specific consumption of each raw material for preparing the copper-iron master alloy masterbatch in this embodiment is (wt.%): Fe=48%; Ni=0.25%; La=0.02%; Ce=0.04%; Cu=51.69%; The composition of the master alloy masterbatch (1#) is shown in Table 1, and the metallographic microscopic morphology of the master alloy is shown in figure 2 ,Depend on figure 2 It can be seen from the data in Table 1 that the chemical composition of the copper-iron master alloy prepared by the present invention is stable, and the composition of the upper, middle and lower parts of the ingot is uniform; the Fe element is evenly distributed in the master alloy without segregation.

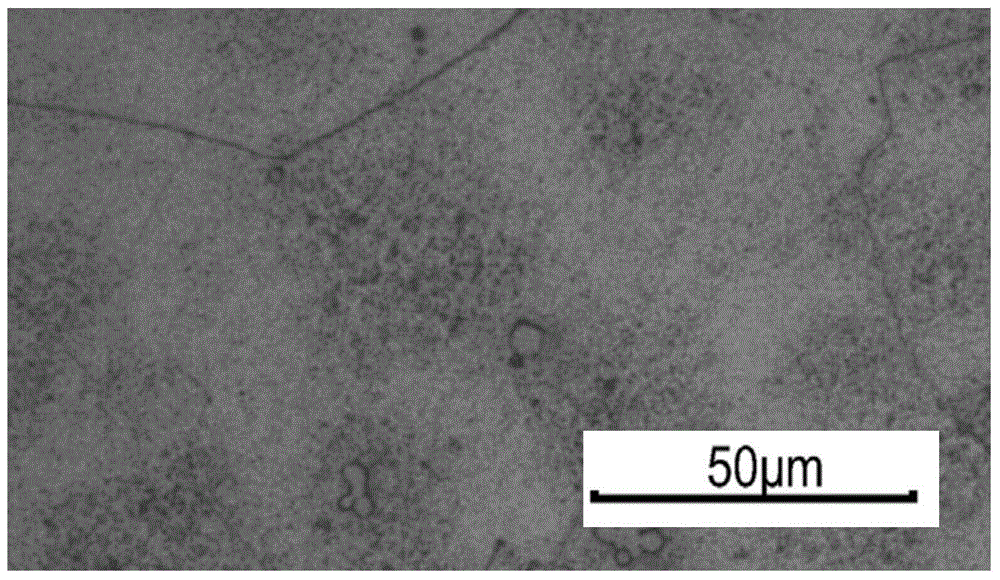

[0073] 2. Prepare high ductility CuFe alloy, the chemical composition is designed as (wt.%): Fe=4.8%, Cu=95.2%. The composition of the prepared copper-iron alloy ingot is shown in Table 2. The chemical composition of the ingot is stable, and the composition of the upper, middle and lower parts of the ingot ...

Embodiment 2

[0076] 1. The specific amount of each raw material for preparing the copper-iron master alloy masterbatch in this embodiment is (wt.%): Fe=51%; Ni=0.28%; La=0.025%; Ce=0.045%; Cu=48.65%;

[0077] 2. Prepare high ductility CuFe alloy, the chemical composition is designed as (wt.%): Fe=5.0%, Cu=95.0%. The composition of the prepared copper-iron alloy ingot is as shown in Table 2, the chemical composition of the ingot is stable, and the upper, middle and lower components of the ingot are uniform;

[0078] 3. The CuFe alloy ingot is processed into Ф0.06mm wire. After testing, the tensile strength of the Ф0.06mm wire is ≥400N / mm 2 ; The elongation rate is 13-16%; the copper-iron alloy also has excellent electromagnetic shielding effect.

Embodiment 3

[0080] 1. The process of preparing the copper-iron master alloy masterbatch in this embodiment is the same as in embodiment 1.

[0081] 2. Prepare high ductility CuFe alloy, the chemical composition is designed as (wt.%): Fe=5.2%, Cu=94.8%. The composition of the prepared copper-iron alloy ingot is as shown in Table 2, the chemical composition of the ingot is stable, and the upper, middle and lower components of the ingot are uniform;

[0082] 3. The CuFe alloy ingot is processed into Ф0.06mm wire. After testing, the tensile strength of the Ф0.06mm wire is ≥400N / mm 2 ; The elongation rate is 13-16%; the copper-iron alloy also has excellent electromagnetic shielding effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com