Multi-point feeder for inserting reinforcement cage after drilling and grouting piles and its application method

A technology for steel cages and grouting piles, which is applied to sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of bending deformation damage of steel cages, inability to sink, affecting the quality of piles, etc. The effect of improving construction quality and construction efficiency, improving pile-forming efficiency and pile-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

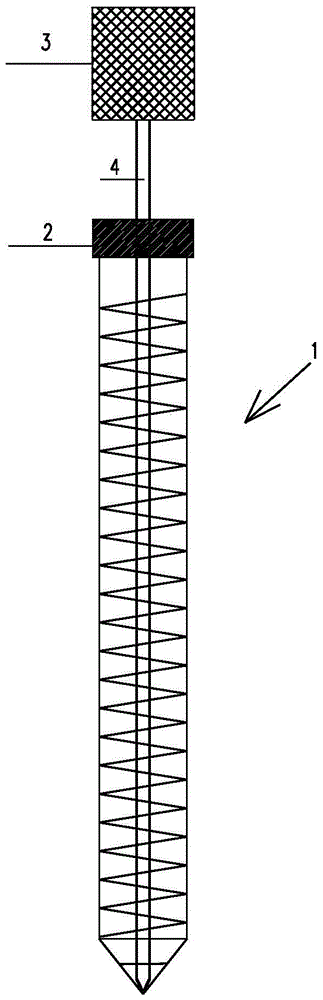

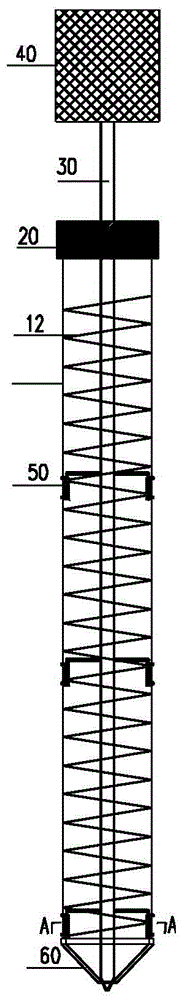

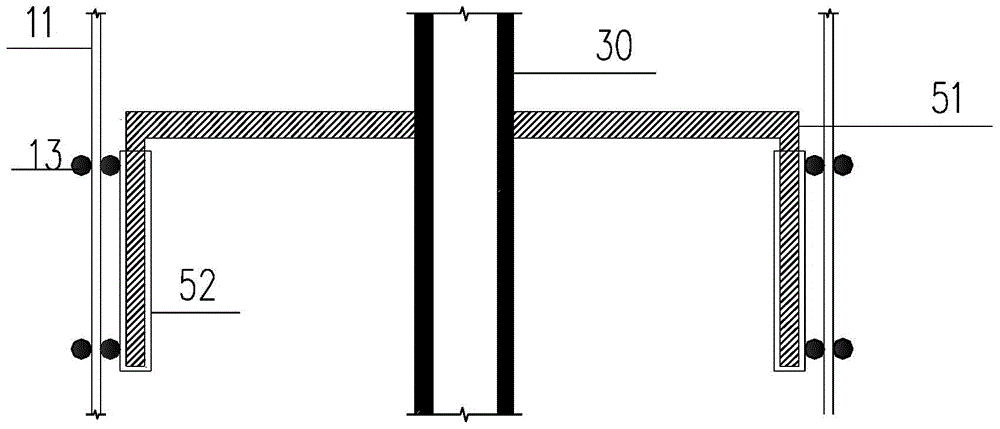

[0031] The multi-point delivery device for inserting reinforcement cages after drilling and grouting piles in this embodiment includes a conversion disc 20 arranged on the top of the reinforcement cage 10; a delivery rod that matches the conversion disc 20 and vertically penetrates the reinforcement cage 10 30; steel hoop 13, the steel hoop 13 includes an inner steel hoop 131 and an outer steel hoop 132, the inner steel hoop 131 and the outer steel hoop 132 are respectively welded to the inner and outer sides of the longitudinal reinforcement 11 of the reinforcement cage 10; one is arranged on the delivery rod 30 The middle and low frequency vibrator 40 at the top; at least one group of multi-point vibration device 50, the multi-point vibration device 50 includes the L-shaped steel bar 51 welded on the delivery rod 30 and the sleeve 52 welded on the inner steel hoop 131, the L-shaped Reinforcing bar 51 is matched with sleeve 52; And spud shoe 60, and spud shoe 60 is the conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com