A circular copper water pipe heated by combustion of a water heater and its manufacturing method

A manufacturing method and water heater technology, which are applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of high gas consumption and increased burning quantity, and achieve the effects of increasing the burning area, reducing the firepower and saving gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

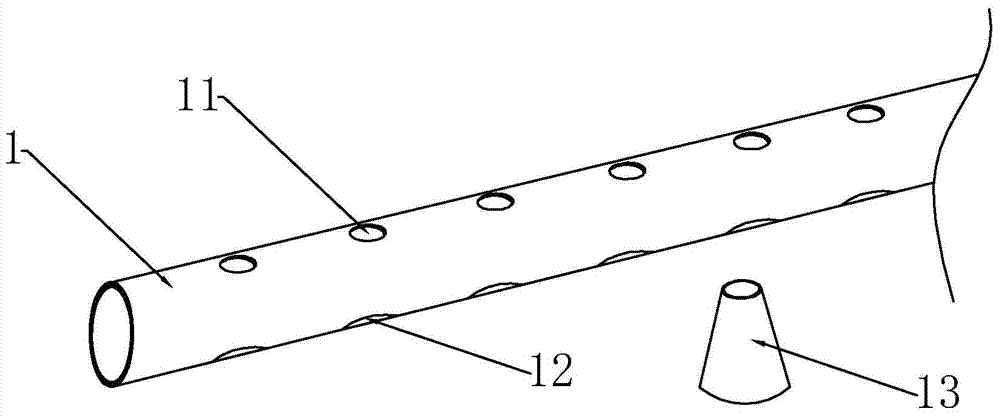

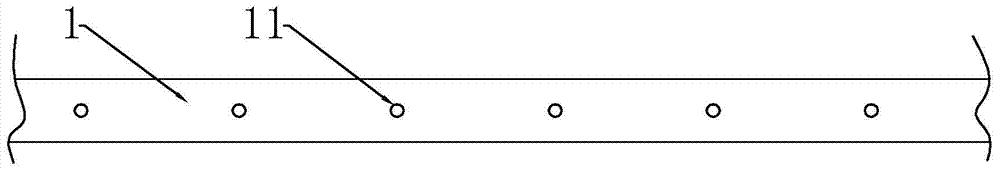

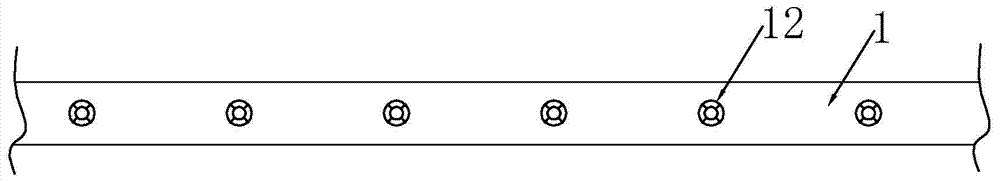

[0025] Such as figure 1 - Figure 4 Shown: a round copper water pipe heated by the combustion of a water heater, characterized in that: the round copper water pipe 1 is drilled with a plurality of upper circular holes 11 and lower circular holes 12 corresponding to the vertical direction. The diameter of the upper circular hole 11 Smaller than the diameter of the lower round hole 12, the upper round hole 11 and the lower round hole 12 are fixed with a tapered inverted copper funnel cup 13 at the same time. The cone of the copper funnel cup 13 is fixed on the hole wall of the upper round hole 11. Fixed on the wall of the lower circular hole 12; the diameter of the upper circular hole 11 is half or less than half the diameter of the lower circular hole 12.

[0026] Further: a circular water pipe heated by the combustion of a water heater, further including a manufacturing method thereof, the manufacturing method is as follows:

[0027] Step 1: Use MASTERCAM or UG or TYPE3 third-part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com