Porous-iron-core-structure micro-fluxgate sensor

A fluxgate sensor, porous structure technology, applied in the magnetic field measurement, the size/direction of the magnetic field and other directions using the magnetic flux control principle, can solve the problems of low current efficiency, serious magnetic leakage, reduction, etc., to reduce the excitation current, The effect of reducing power consumption and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

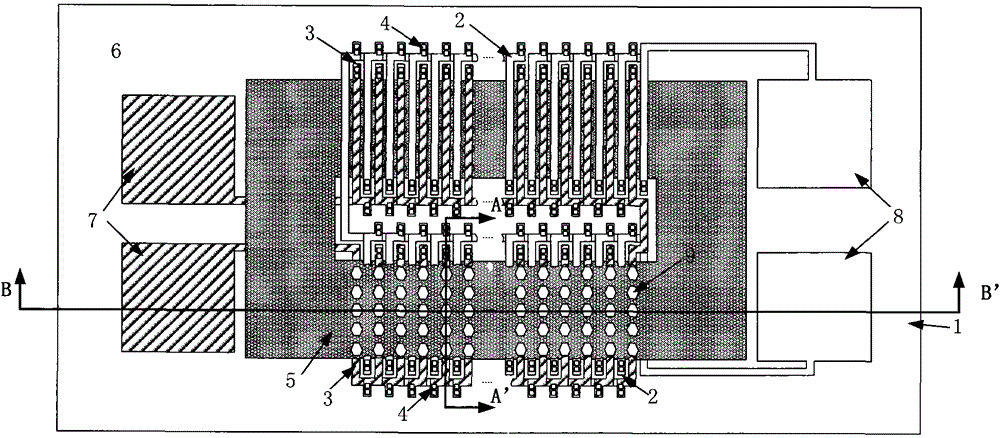

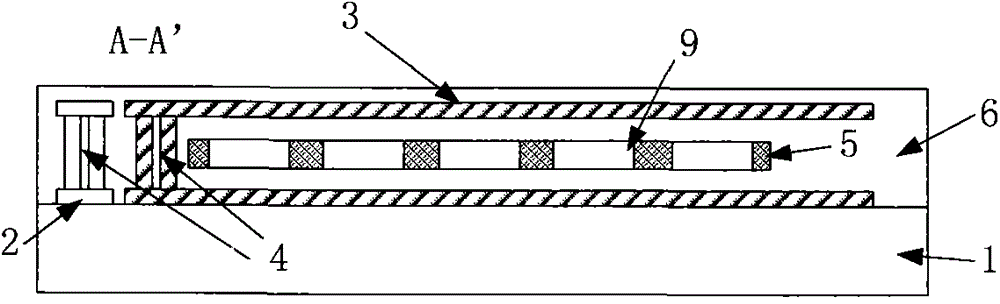

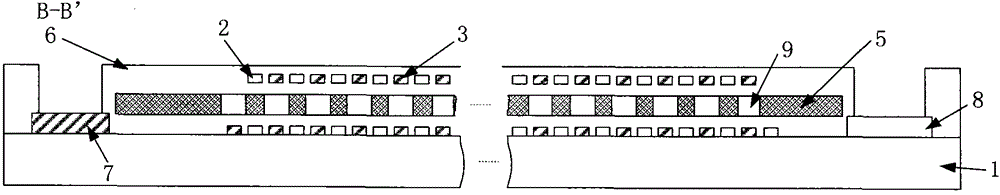

[0028] Example 1: Micro Fluxgate with Honeycomb Holes

[0029] Refer to attached figure 1 , 2, 3, The microfluxgate sensor with porous iron core structure in this embodiment includes a silicon substrate with a silicon dioxide insulating layer to provide support for the entire structure. Double iron core structure is adopted, the two ends of the iron core are connected to form a ring shape, and the iron core has hexagonal holes arranged densely in the vertical iron core axis and spaced apart in the parallel iron core axial direction. These holes divide the iron core into Multiple sets of local variable cross-sectional area structures. Such an iron core layer is surrounded by a three-dimensional solenoid excitation coil and an induction coil perpendicular to it, and polyimide is used as an insulating layer and a protective layer between the induction coil and the iron core. The induction coil and the excitation coil are respectively connected to pads on the substrate.

[003...

Embodiment 2

[0049] Embodiment 2: Miniature Fluxgate with Square Hole

[0050] Refer to attached Figure 5 , 6, 7, The micro-fluxgate sensor with porous iron core structure in this embodiment includes a silicon substrate with a silicon dioxide insulating layer to provide support for the entire structure. Double iron core structure is adopted, the two ends of the iron core are connected to form a ring shape, and the iron core has hexagonal holes arranged densely in the vertical iron core axis and spaced apart in the parallel iron core axial direction. These holes divide the iron core into Multiple groups of local variable cross-sectional area structures. Such an iron core layer is surrounded by a three-dimensional solenoid excitation coil and an induction coil perpendicular to it, and polyimide is used as an insulating layer and a protective layer between the induction coil and the iron core. The induction coil and the excitation coil are respectively connected to pads on the substrate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com