General valve design optimization method

An optimization method and valve technology, applied in computing, special data processing applications, instruments, etc., can solve the problems of lack of systematic, single basis and support, and achieve the effect of speeding up the research and development process, reducing the test cost and shortening the test period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

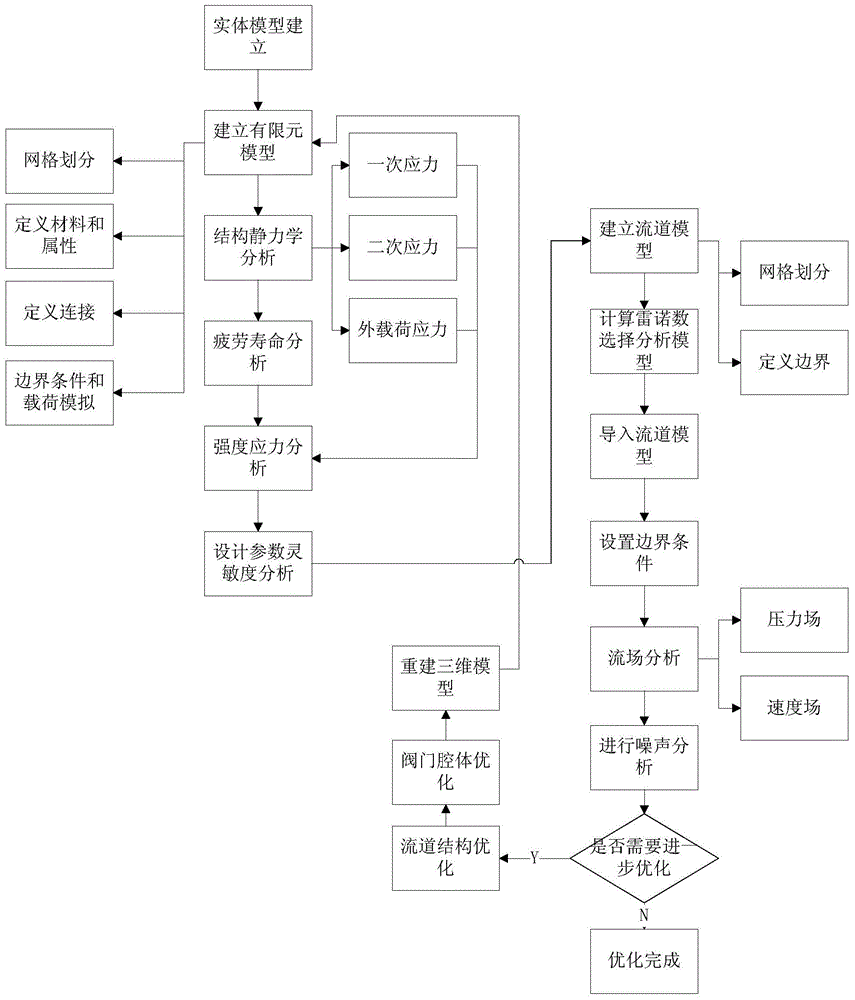

Method used

Image

Examples

Embodiment

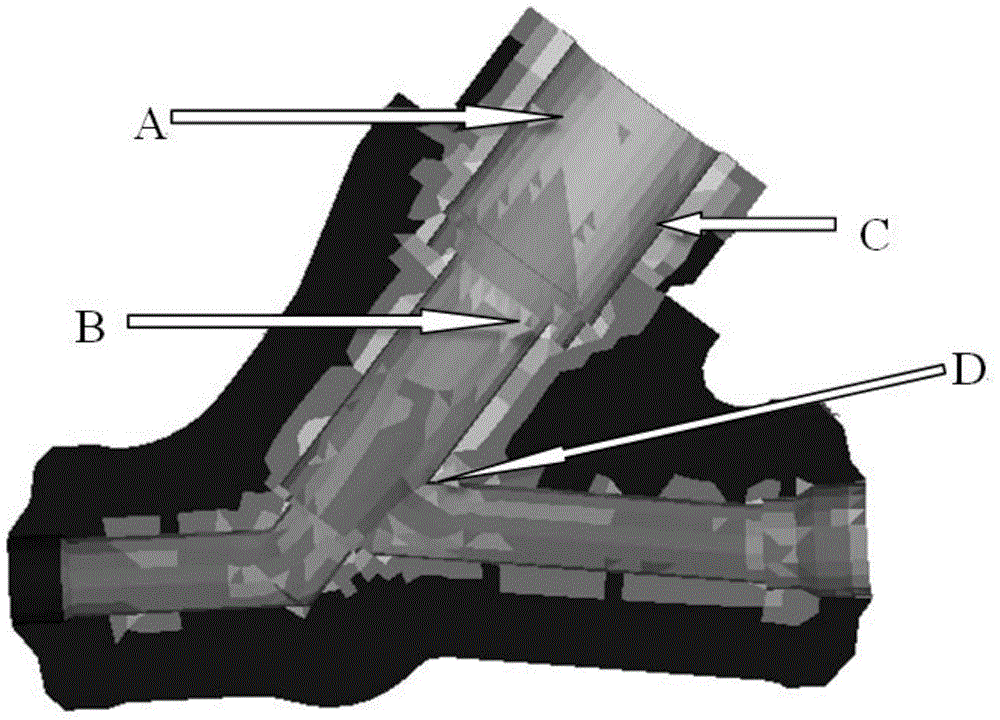

[0041] Using the steam trap as the analysis object, the solid model of the steam trap is established for stress-strain analysis as follows: figure 2 As shown, among them, the stresses in the areas shown in A, B, C, and D are relatively large, and the stress at D is the largest, that is, the maximum stress is mainly distributed in the transition area. Use the primary stress results for the region to compare with the allowable stress values. If the primary stress result obtained from the analysis is greater than the allowable stress, the valve should be strengthened to optimize the stress concentration point. If the primary stress result obtained from the analysis is less than the allowable stress, the valve can be evaluated as qualified for the stress stiffness design and enter the trial production test stage. If the primary stress result obtained from the analysis is far less than the allowable stress, the valve should be lightweight designed to reduce the material used on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com