Coupled modeling method for vibration piezoelectric energy harvesting system

A modeling method and vibration voltage technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of high electric energy conversion efficiency, output AC voltage change, and impact on the overall conversion efficiency of the vibration piezoelectric energy harvesting system, etc. problem, to achieve the effect of simple calculation process and small amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

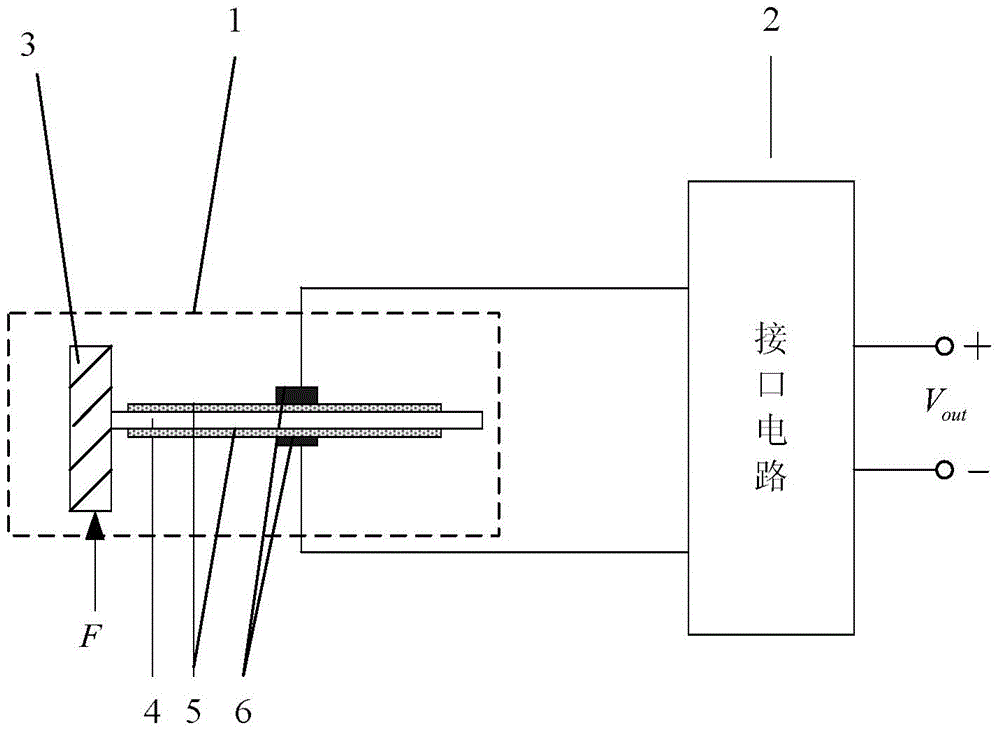

[0031] In order to facilitate the understanding of the present invention, the basic structure of the vibrating piezoelectric energy harvesting system in the prior art is firstly introduced. Such as figure 1 A structural schematic diagram of a vibrating piezoelectric energy harvesting system is shown; it includes a piezoelectric power generation structure 1 and an interface circuit 2. The piezoelectric power generation structure includes a base 3, an elastic substrate 4, a piezoelectric ceramic sheet 5 and two electrodes 6; the elastic substrate One end of 4 is clamped on the base 3 to form a cantilever beam; the piezoelectric ceramic sheet 5 is pasted on the upper and lower surfaces of the elastic substrate 4; the electrodes 6 are respectively plated on the upper and lower outer surfaces of the piezoelectric ceramic sheet 5; the interface The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com