A pump circulation anti-clogging device for high-efficiency pressure filtration of basic magnesium carbonate

A magnesium carbonate filter press, anti-clogging technology, applied in the directions of magnesium carbonate, filtration separation, separation methods, etc., can solve the problem that the working performance of the filter press cannot be fully utilized, the working efficiency is increased, the filter pressure resistance is increased, and the pressure filtrate flow rate is small, etc. problems, to achieve the effect of simple structure, preventing material clogging and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

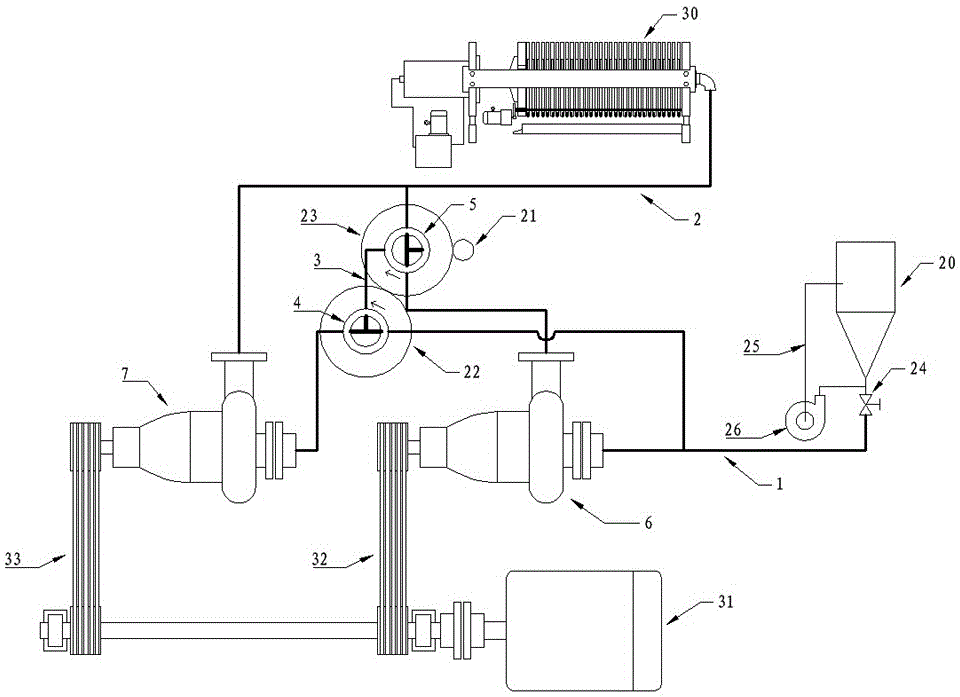

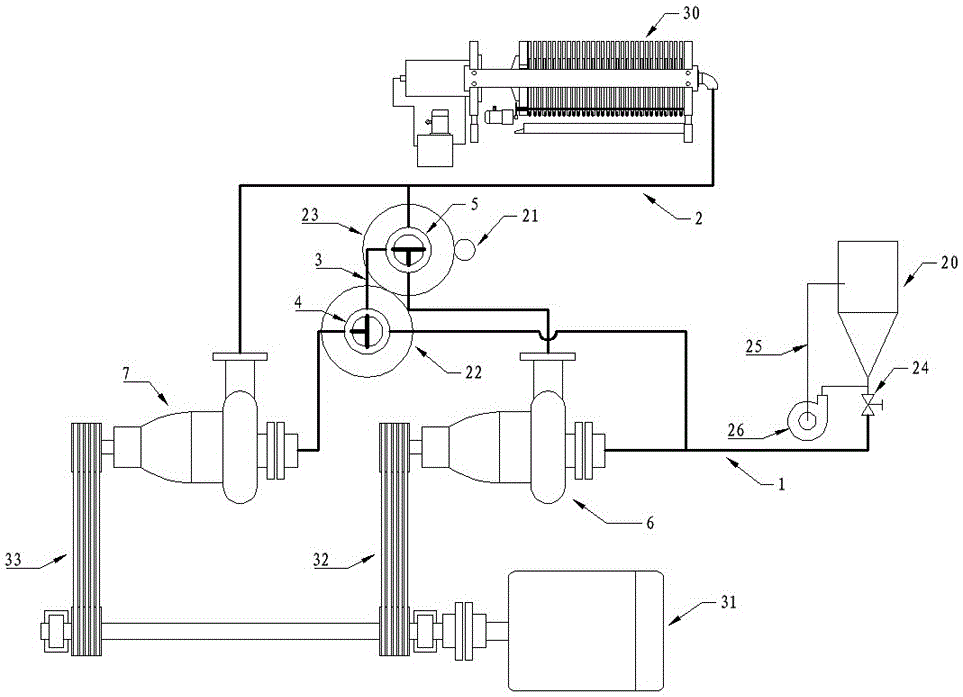

[0017] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0018] Such as figure 1 with figure 2 The pump circulation anti-clogging type shown is a device for high-efficiency filter press of basic magnesium carbonate, including inlet pipe 1, two centrifugal pumps (6, 7), outlet pipe 2, basic magnesium carbonate filter press, and two centrifugal pumps 6 and 7 are driven by the same motor 31; the inlet pipe 1 is branched into two pipes, one pipe is connected to the outlet pipe 2 through the three-way cock 4 and the centrifugal pump 7, and the other pipe is passed through another centrifugal pump 6 and another three-way cock 5 is connected to the outlet pipe 2; two three-way cocks 4 and 5 are provided with gears 22 and 23 to drive the valve core to rotate, and the gears 22 and 23 of the two three-way cocks are meshed with each other and driven by a driving gear 21 to realize two The rotation switch of three-way cock 4,5, two th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com