Machining process for machining through hole in workpiece on disc machine

A processing technology and disc machine technology, applied in metal processing, metal processing equipment, drilling tool accessories, etc., can solve the problems of reducing processing efficiency, damage, increasing production and processing costs, etc., to save processing costs, improve processing efficiency, The effect of saving production and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

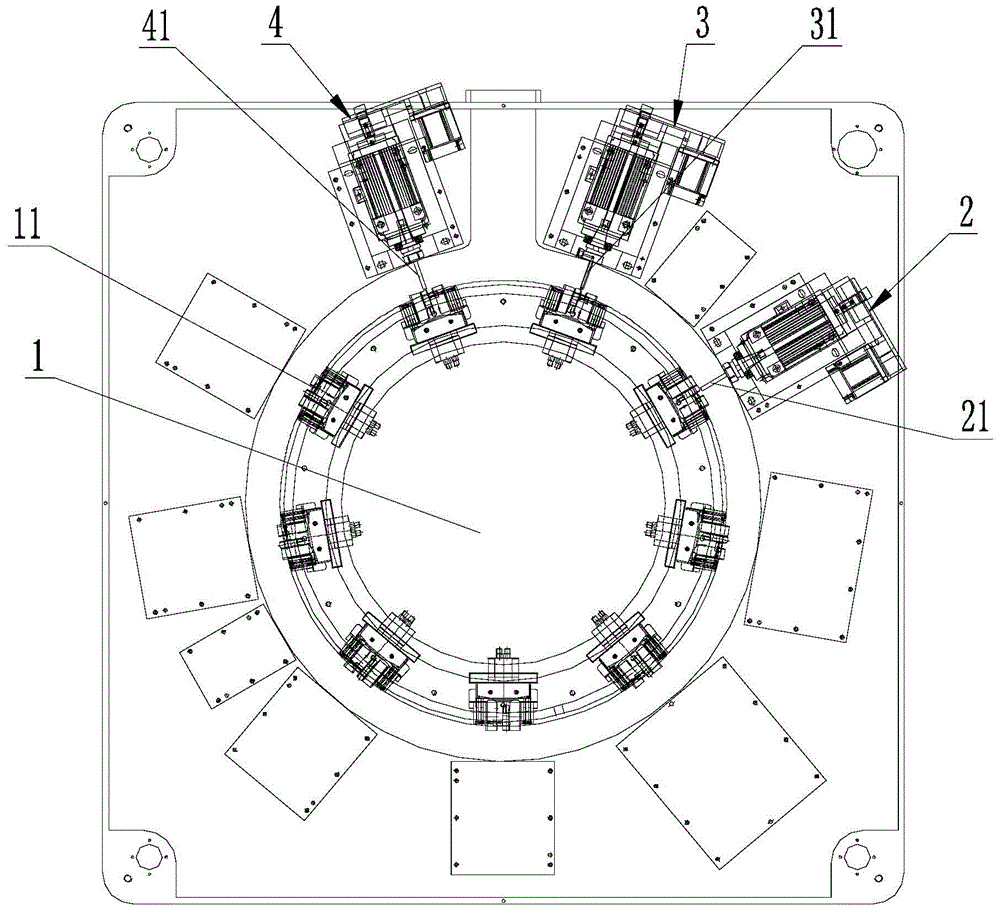

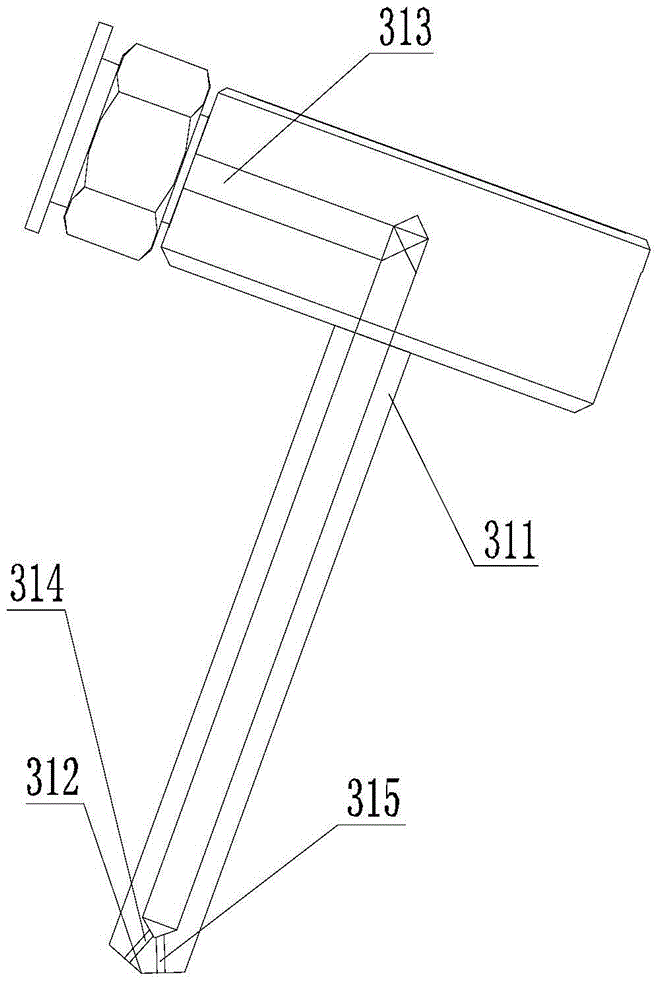

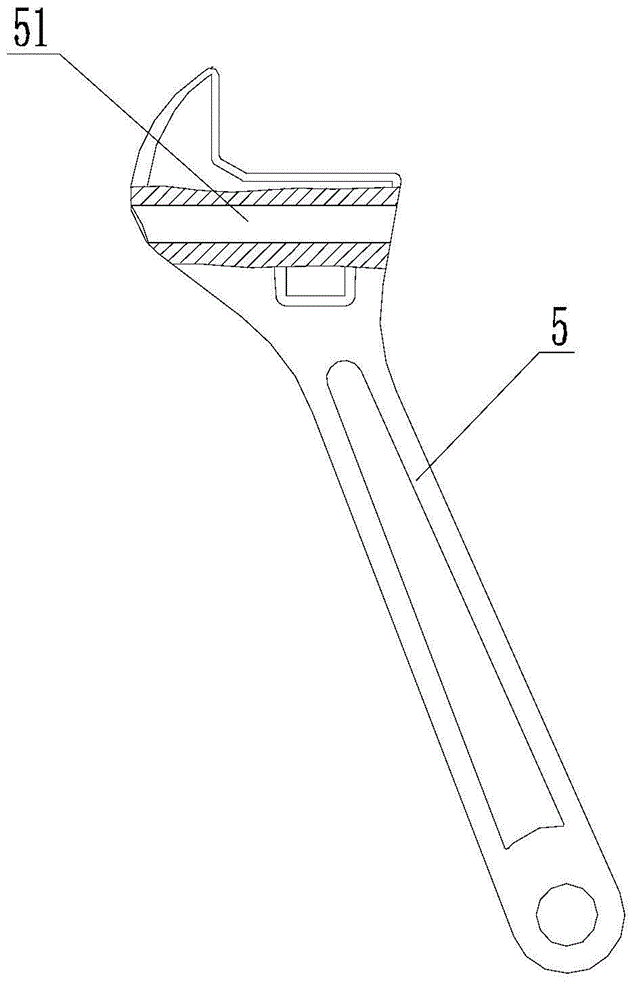

[0018] see Figure 1-3 Shown, above-mentioned a kind of processing technology that is used for the through-hole processing of workpiece on the disc machine. The disc machine includes a rotating disc 1 on a base for driving the workpiece 5 to rotate around its axis, and a processing mechanism on the base for processing the workpiece 5 . A plurality of clamping pieces 11 are evenly spaced on the outer peripheral portion of the rotating disk 1 , and the workpiece 5 is clamped on the side of the rotating disk 1 by the clamping pieces 11 and rotates together with the rotating disk 1 . The processing mechanism at least includes a first processing mechanism 2 , a second processing mechanism 3 and a third processing mechanism 4 which are arranged around the outer peripheral portion of the rotating disk 1 and distributed therebetween. In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com