Electrochemical liquid tank

An electrochemical and liquid tank technology, applied in the field of electrochemical liquid tanks, can solve the problems of workpiece surface damage, unusability, submersible electric pump damage, etc., and achieve the effect of improving surface quality, reducing damage, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

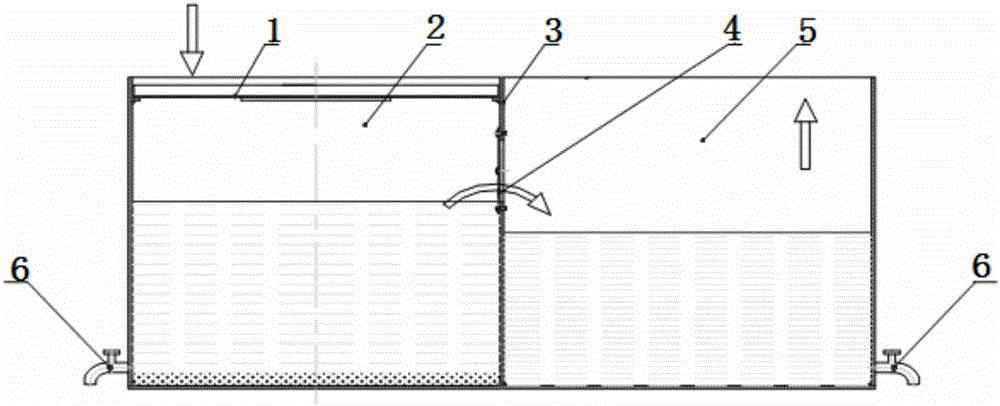

[0010] Such as figure 1 As shown, the present invention provides a kind of electrochemical liquid tank, comprises casing, is divided into sedimentation pond 2 and circulation pond 5 by separating plate 3 in the middle of this casing, wherein on sedimentation pond 2 there is electrochemical liquid circulation inlet and There is an electrochemical liquid circulation outlet on the circulation pool 5, and a primary filter screen is provided on the top of the aforementioned sedimentation tank 2. The material of the primary filter screen is 0Cr18Ni9 stainless steel, and the number of meshes is 300 meshes to filter impurities with large particles. A secondary filter is provided in the middle of the aforementioned isolation plate 3, and the material of the secondary filter is 0Cr18Ni9 stainless steel with a mesh number of 600 mesh to filter impurities with small particles 4 . The sedimentation tank can also effectively precipitate the electrochemical solution.

[0011] In addition, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com