Tail positioning device for motorcycle frame welding tool

A frame welding and positioning device technology, applied in the field of tooling and fixtures, can solve the problems of not being able to catch up with the launch of the product, long preparation time, high product cost, etc., and achieve the effect of flexible disassembly, complete interchangeability, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

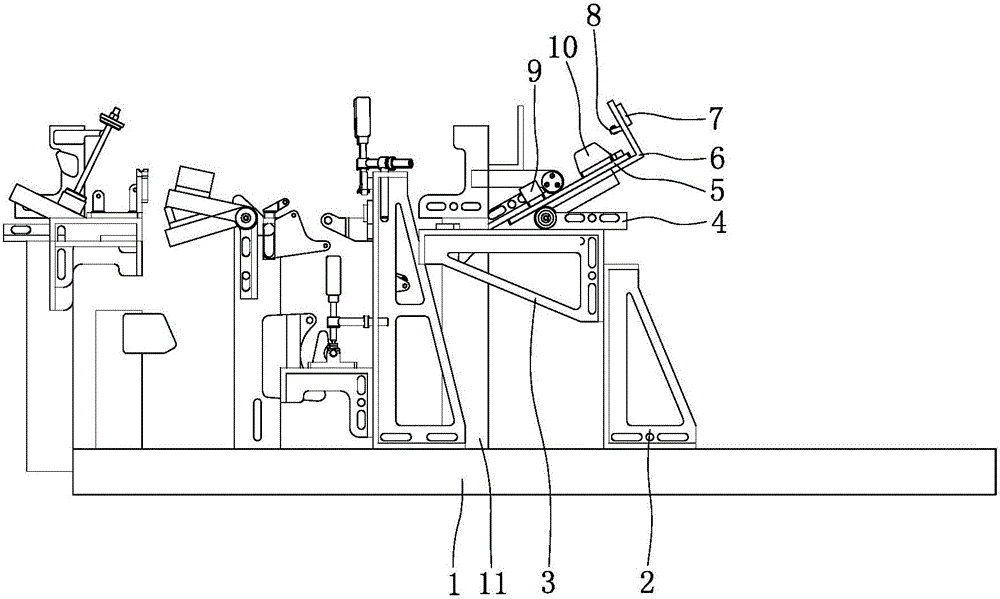

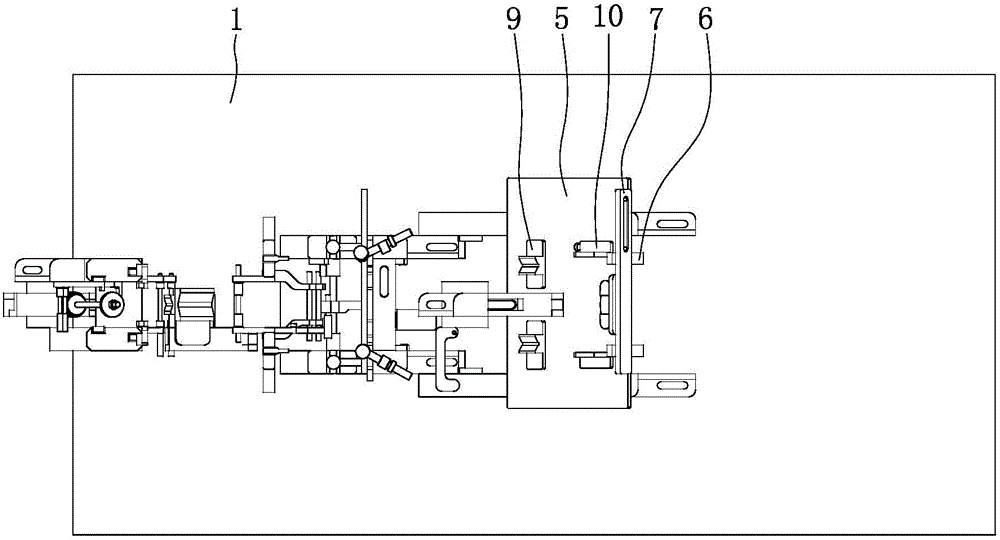

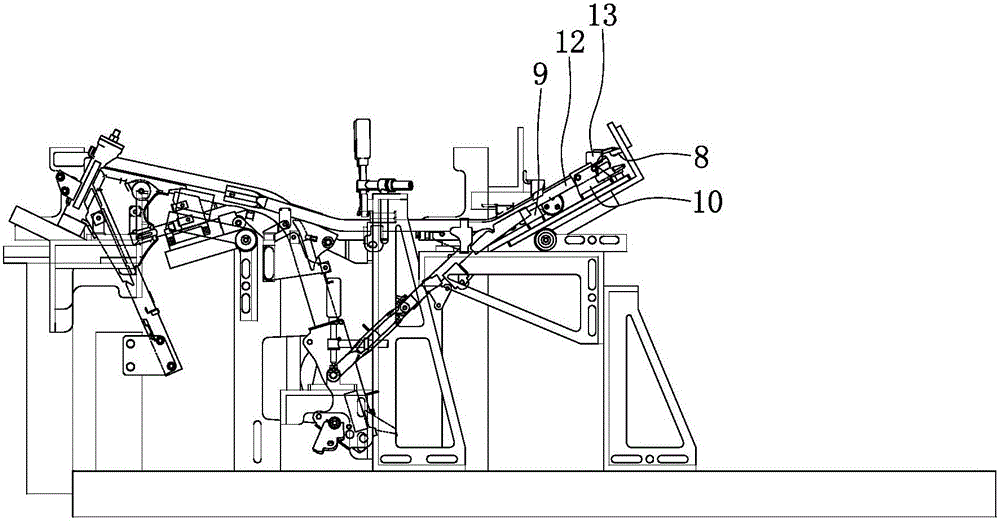

[0021] Such as figure 1 , figure 2 As shown, the working platform 1 is rectangular, and optional holes are arranged in a matrix on the top surface of the working platform 1, and optional holes are evenly arranged on the peripheral side of the working platform 1, and the aperture and size of the optional holes can be selected according to the actual situation. Need to be sure. Two left-right symmetrical vertical tripods 2 are arranged at the middle rear part of the working platform 1, and the bottom of the vertical tripods 2 are fixedly connected with the working platform 1 by bolts. The front side of each vertical tripod 2 top is provided with a horizontal tripod 3, and the rear end face of the horizontal tripod 3 fits with the front end face of the vertical tripod 2 top, and the horizontal tripod 3 and the vertical tripod 2 connected by bolts. Square bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com