Elastic screen mesh lunar vehicle wheel

A lunar rover and wheel technology, applied in the direction of wheels, rims, vehicle parts, etc., can solve the problems of few reports of wheel configuration and small wheel radius, and achieve the advantages of extending the driving range on a single charge, increasing the traction force, and quickly changing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

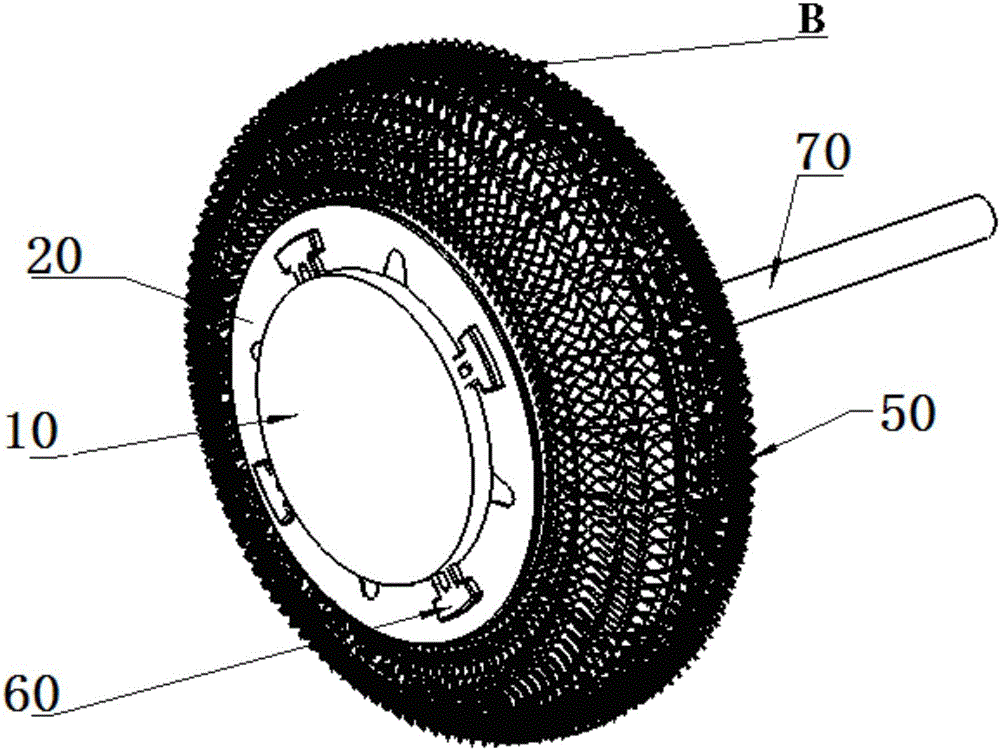

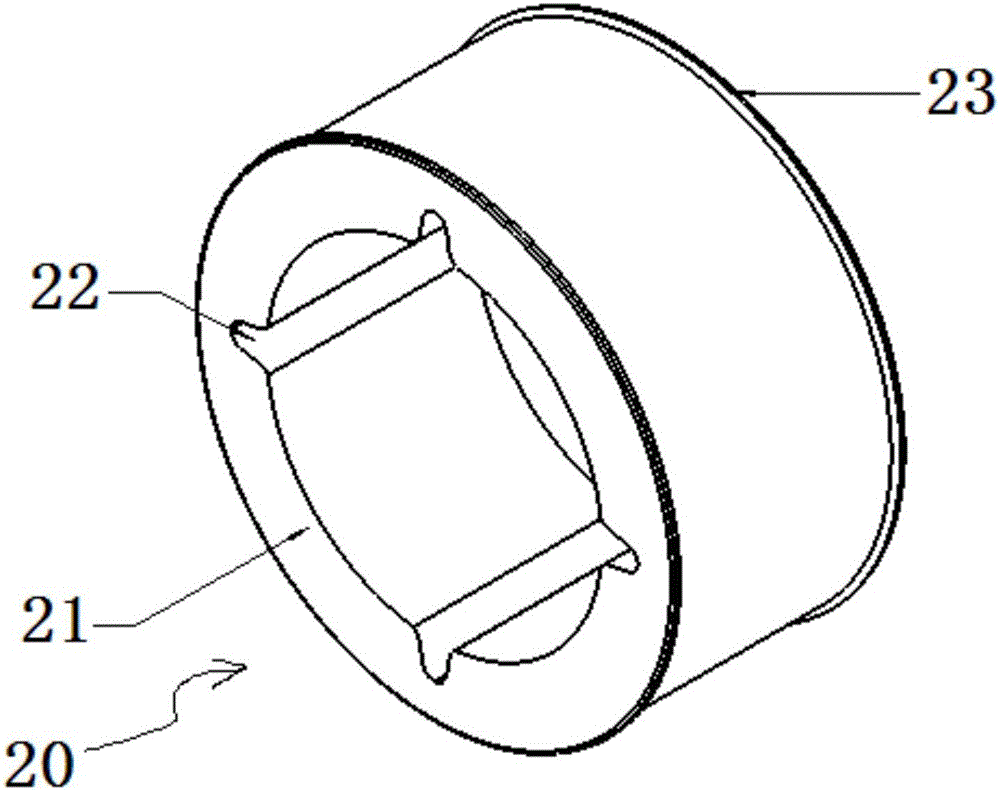

[0036] like Figure 1-Figure 6 As shown, a lunar rover wheel with an elastic screen mesh includes a hub 10, a rim 20, a wheel frame 30, a core 40, and a metal braided mesh screen tire 50. Wherein, the rim 20 is arranged outside the hub 10 and fixed in the axial direction by the bolt 60 . A wheel frame 30 is arranged outside the wheel rim 20 , a tire core 40 is arranged in the wheel frame 30 , and a braided screen mesh cover tire 50 is fixed on the outer edge of the wheel rim 20 to wrap the wheel frame 30 .

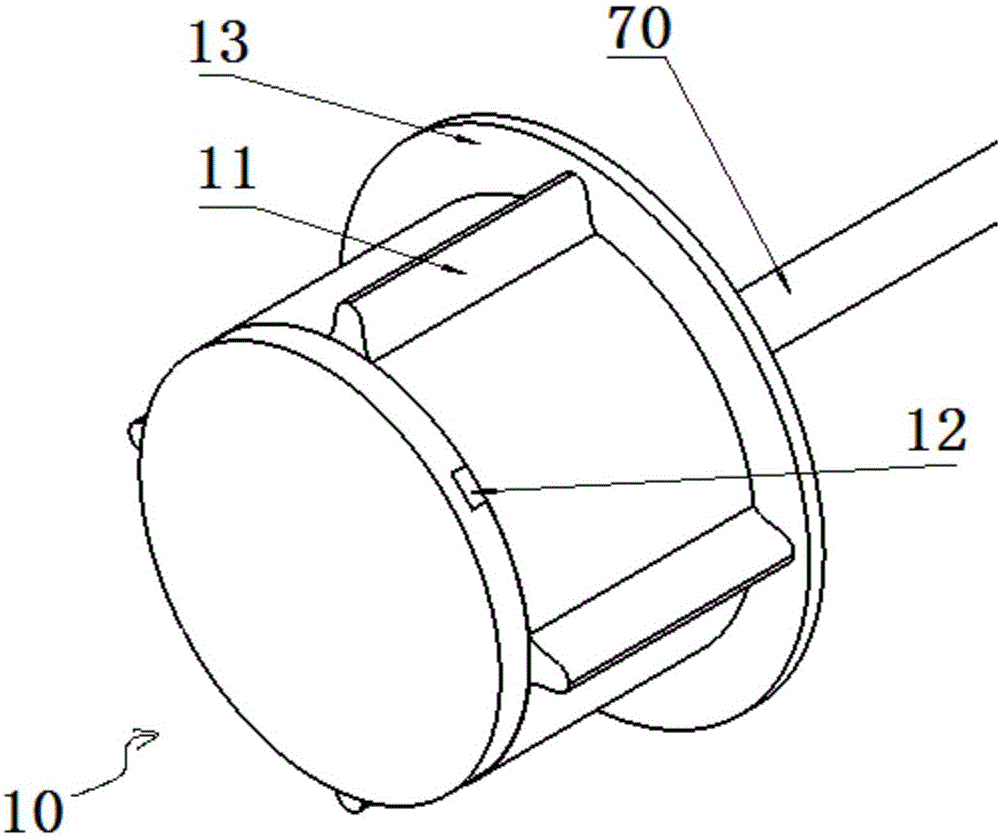

[0037] like figure 2 As shown, the hub 10 is connected to the axle 70, and an independent driving motor is arranged inside. The end of the wheel hub 10 near the body is provided with a hub baffle 13 with an increased radius, and the hub baffle 13 is integrated with the wheel hub 10 to limit the movement of the rim 20 along the axis toward the veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com