Environment-friendly mortise and tenon joint type dense-gap wall brick

A mortise and tenon type, environmentally friendly technology, applied in thermal insulation, building components, sound insulation, etc., can solve problems such as slow construction progress, difficult to maintain quality, property damage, etc., to reduce construction hours, reduce error losses, and strong earthquake resistance effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

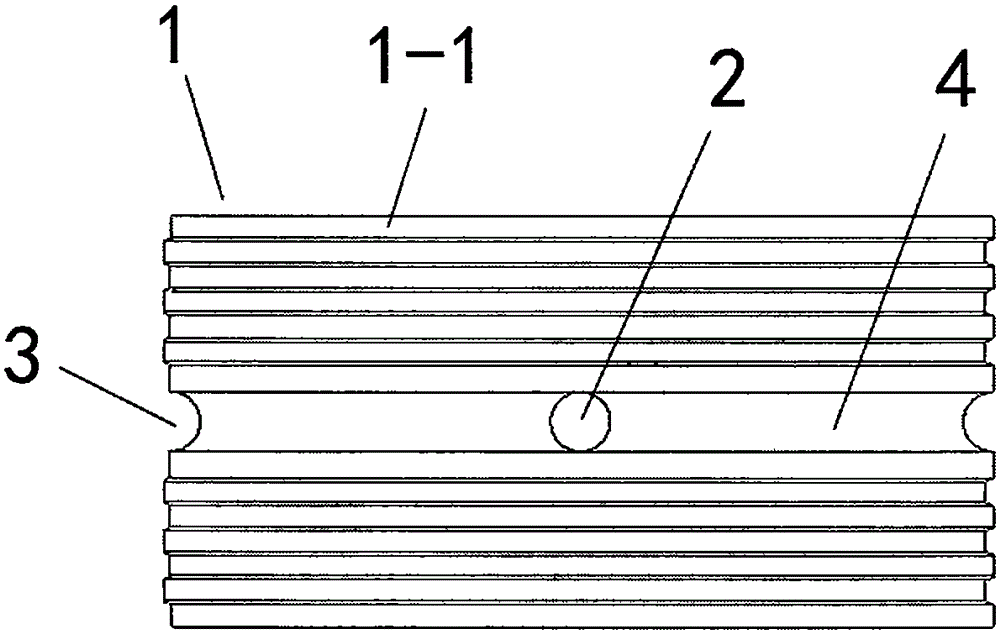

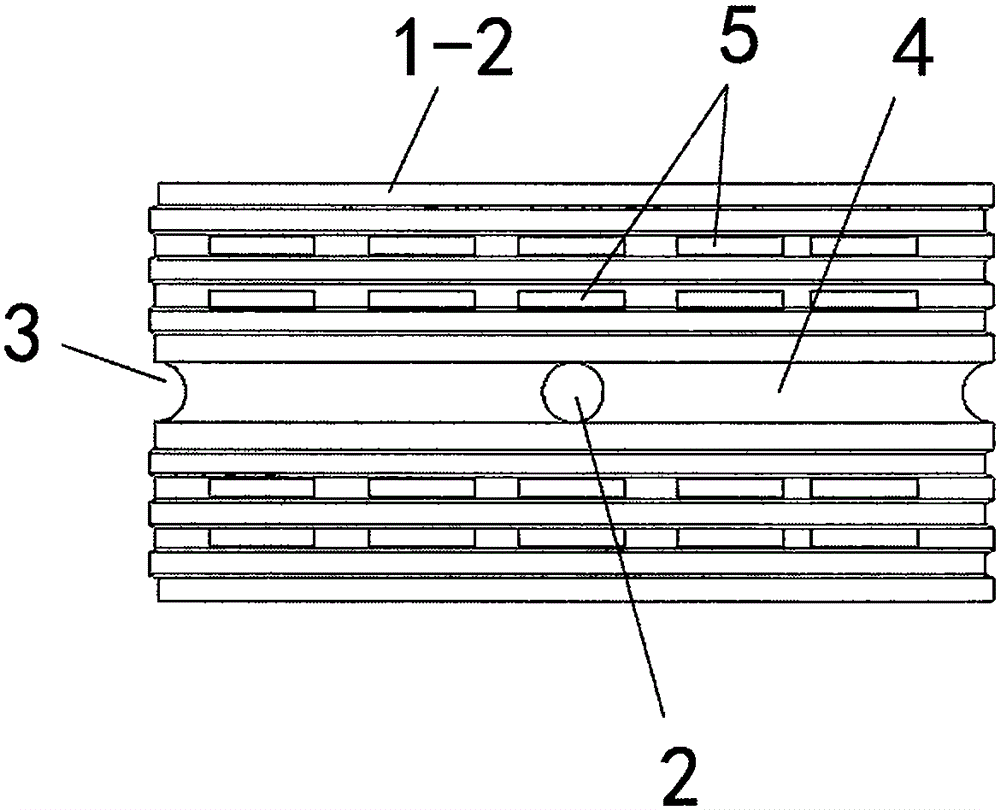

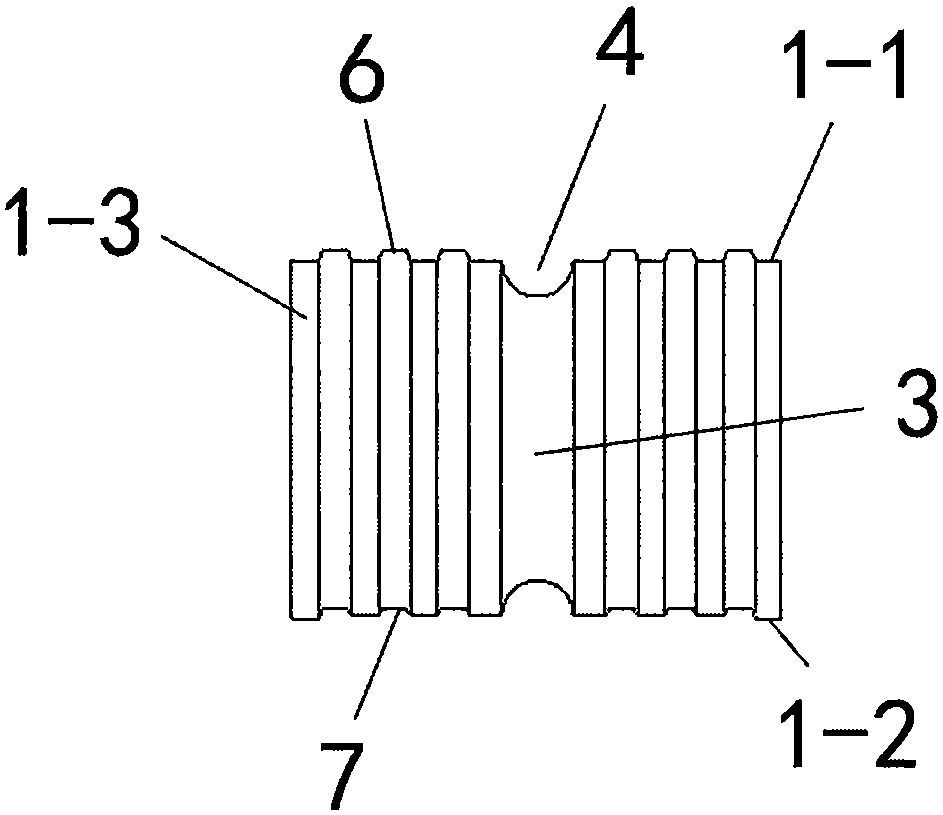

[0025] Such as Figure 1 to Figure 4 As shown, an environment-friendly mortise and tenon type close-gap wall brick includes a body 1, the body 1 is in the shape of a cuboid or a cube, the top surface 1-1 and the bottom surface 1-2, the left side 1-3 and the right side of the body 1 are 1-4 are all provided with mortise and tenon structures that cooperate with each other, wherein the top surface 1-1 and the left surface 1-3 are tenon structures 6, the bottom surface 1-2 and the right surface 1-4 are mortise structures 7; There is a circular central through hole 2 perpendicular to the top surface 1-1 and the bottom surface 1-2; the left side 1-3 and the right side 1-4 of the body 1 are provided with a half cylinder parallel to the circular central through hole 2 shaped longitudinal groove 3; the top surface 1-1 and the bottom surface 1-2 of the body 1 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com