Method for preparing fabric with lasting cool touch sense

A cooling and fabric technology, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problem of losing the cooling effect and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 30” / 32G Delo UP472 machine is used for the large circular knitting machine, 75D / 72F cool-touch filament is used for the skin-adhering surface, and 75D / 72F cationic modified polyester filament is used for the flower-shaped surface. The cool-touch filament has a skin-core structure and is long The "skin" of the silk is composed of nylon 66, and the "core" is composed of cationic modified polyester. The cross-section of the filament is cross-shaped, and the surface is grooved to form a wicking effect.

[0042] The thread length of the cool touch filament is 25.8cm / 100N, and the thread length of the cationic modified polyester filament is 28.3cm / 100N. The braiding tension is controlled at 5-6cN.

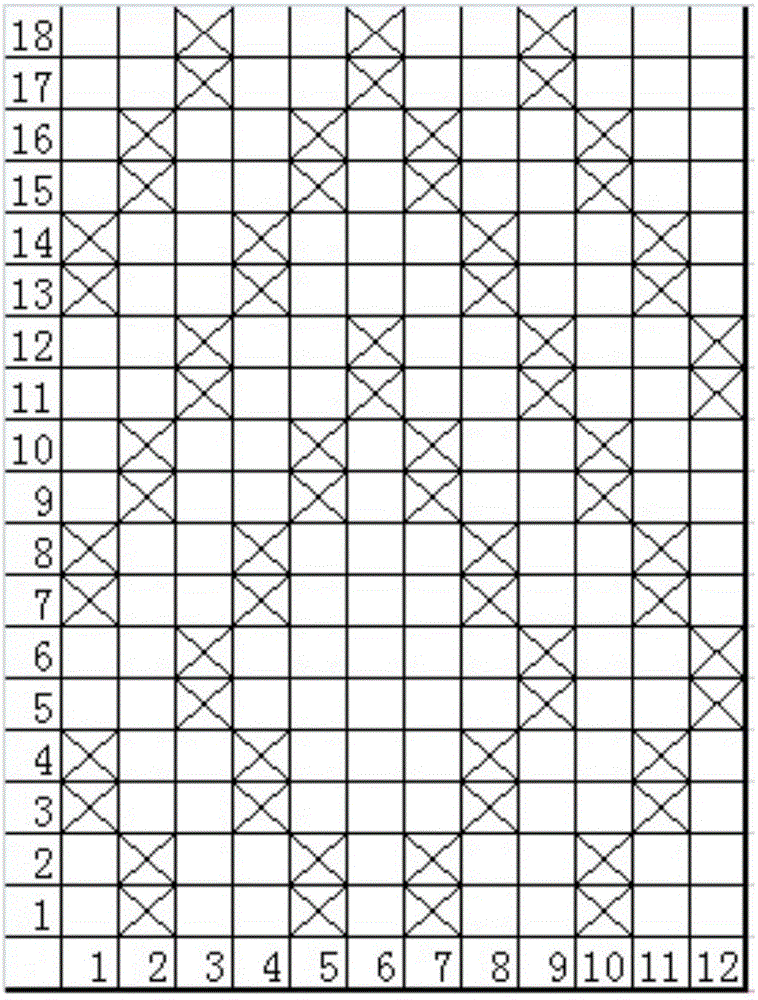

[0043] Flower shape artisan picture such as figure 1 shown. .

[0044] After dyeing and finishing, the final light billet weight is 150g / m 2 , according to GB / T 21655.1, 30min test climbing, before washing, it is 16.5cm in width and 19cm in length; after washing, it is 21.5cm...

Embodiment 2

[0046] 30” / 32G Delo UP472 machine is used for the large circular knitting machine, 75D / 72F cool-touch filament is used for the skin-adhering surface, and 75D / 72F cationic modified polyester filament is used for the flower-shaped surface. The cool-touch filament has a skin-core structure and is long The "skin" of the silk is composed of nylon 66, and the "core" is composed of cationic modified polyester. The cross-section of the filament is cross-shaped, and the surface is grooved to form a wicking effect.

[0047] The thread length of the cool touch filament is 25cm / 100N, and the thread length of the cationic modified polyester filament is 28.6cm / 100N. The braiding tension is controlled at 5-6cN.

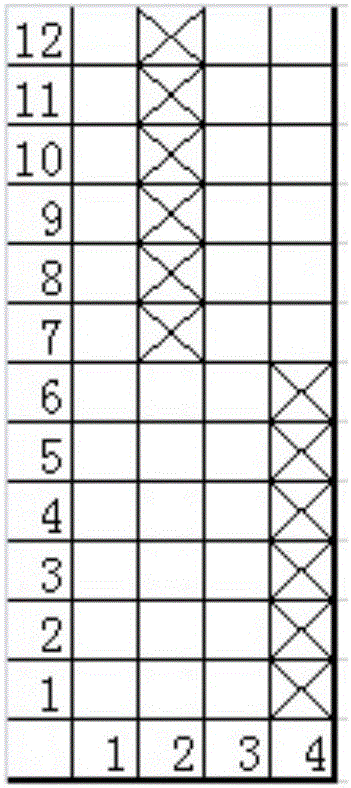

[0048] Flower shape artisan picture such as figure 2 shown.

[0049] After dyeing and finishing, the final weight of the blank is 170g / m 2 , according to GB / T 21655.1, 30min test climbing, before washing, it is 15.6cm in width and 17.6cm in length; after washing, it is 17.5cm in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com