A segmented trace hinge moment balance

A hinge moment, segmented technology, applied in the direction of measuring devices, aerodynamic tests, instruments, etc., can solve the problems that the influence of temperature cannot be ignored, the working environment is harsh, and the hinge moment balance cannot use water-cooled heat-proof structure, etc., to achieve Wide application range, improved sensitivity, and the effect of measuring small loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

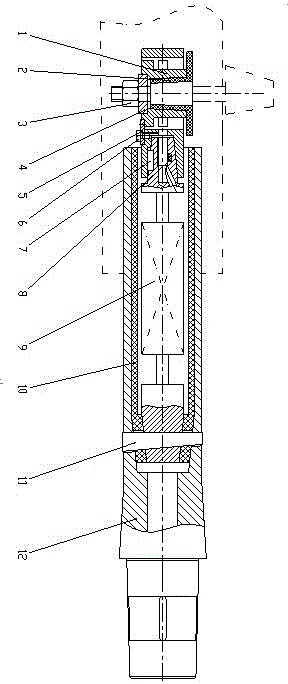

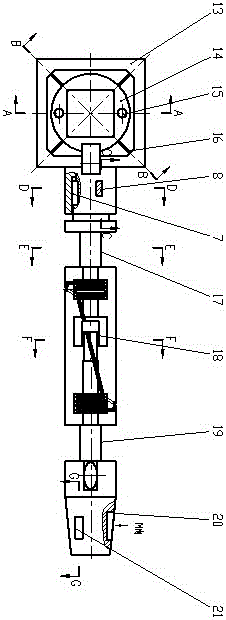

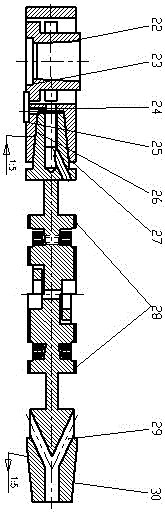

[0040] A segmented micro hinge moment balance of the present invention adopts a segmented structure in order to measure the trace hinge moment of the full motion rudder model, which consists of a single component micro hinge moment balance, a six component balance, a heat insulation The heat device and the limit protection device are composed of four parts.

[0041] The design load of a segmented micro hinge moment balance of the present invention is that the normal force Y component is 30N, the pitching moment Mz component is 1.8N.m, the axial force X component is 30N, and the rolling moment Mx component is 0.06N.m. The X-direction force component is 20N, and the yaw moment My component is 0.8N.m. The test Mach number ranges from 5 to 10, and the flow field temperature is 800°C.

[0042] Such asfigure 1 As shown, it is an assembly diagram of a segmented micro hinge moment balance of the present invention. The present invention is a segmented all-steel composite structure, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com