Automobile steering track rod assembly and ball head pin test device

A technology of steering tie rod and test device, which is applied in the direction of measuring device, vehicle test, mechanical component test, etc., can solve the problems of large investment, wide area, low use efficiency, etc. The effect of land area and improvement of use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

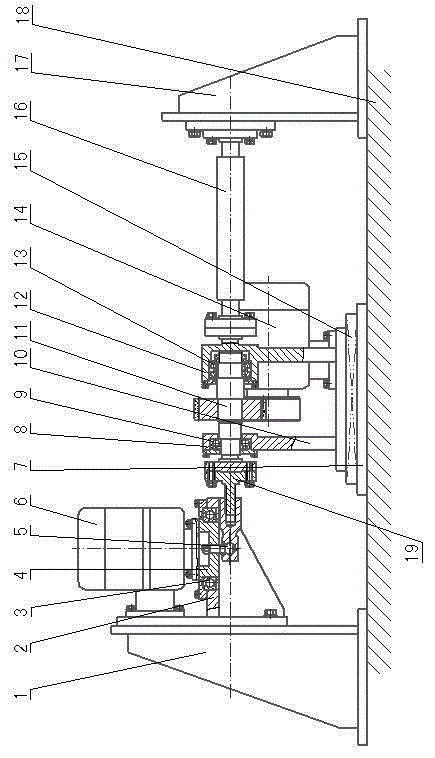

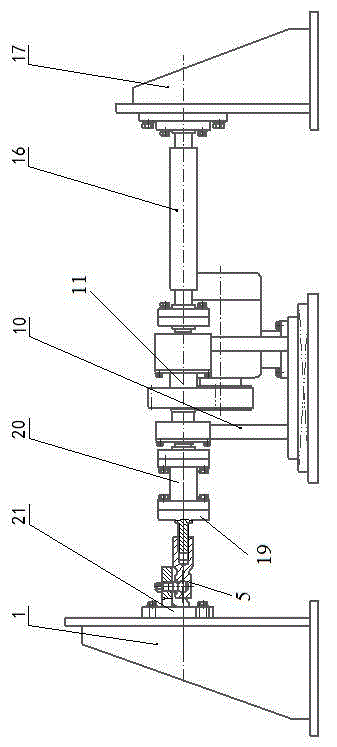

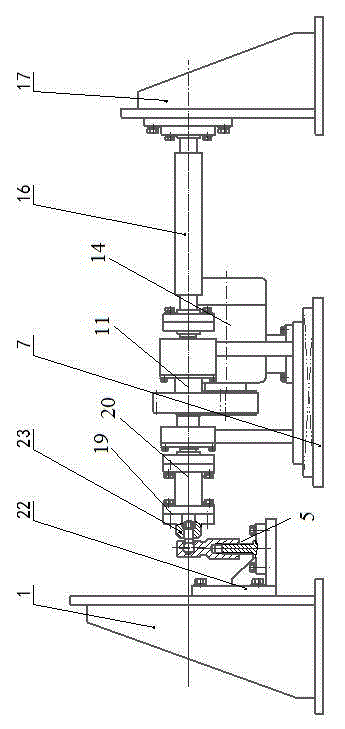

[0019] like Figure 1-4 As shown, the present invention includes a body 18, a left support 1, a middle support 7 and a right support 17, the left support 1, the middle support 7 and the right support 17 are all arranged on the body 18, and the middle support 7 A moving bracket 10 is provided, and an actuator 16 (preferably a hydraulic actuator, preferably a hydraulic actuator, is connected between the moving bracket 10 and the right support 17) that drives the moving bracket 10 to perform linear reciprocating motion on the intermediate support 7 along the axis of the actuator. It is more preferable to have a hydraulic actuator with a universal joint, so as to minimize the damage to the actuator caused by the lateral force from the sample; when a hydraulic actuator with a universal joint is used, the moving bracket 10 is connected with the universal joint through the universal joint. Hydraulic actuator 16 is connected). A first mounting position is provided on the left support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com