A color separation and stripping machine

A wire stripping machine and color separation technology, applied in the direction of circuit/collector parts, electrical components, circuits, etc., can solve the problems of inconsistent length of three-core wires, large manual workload, large length error, etc., to save manpower The effect of cost, high degree of automation and qualified product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

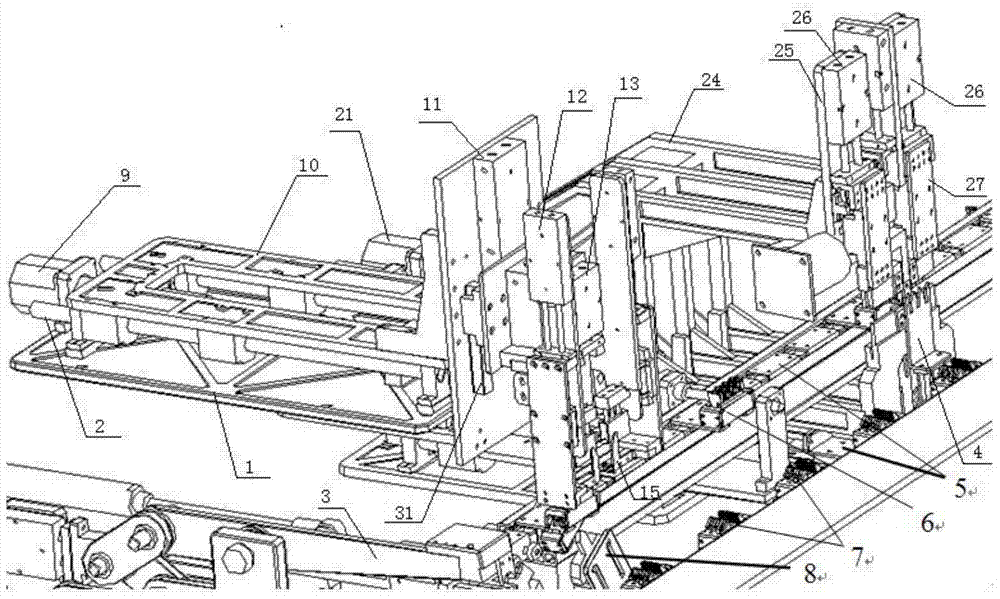

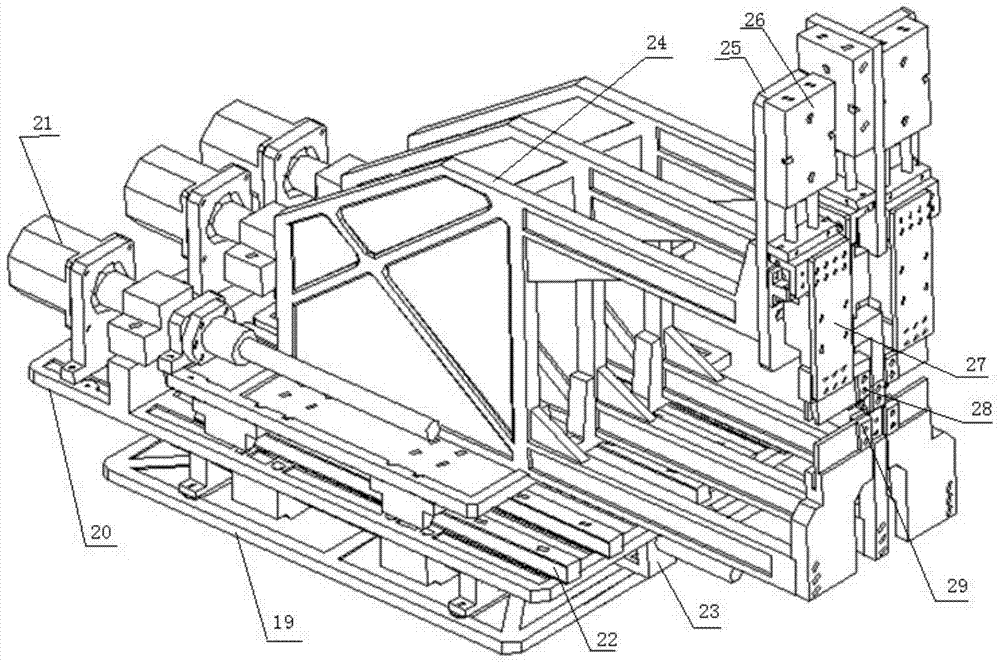

[0022] As shown in the figure, a color separation wire stripping machine, (1) is characterized in that it is composed of a threading device, a color recognition device and a color separation and cutting device;

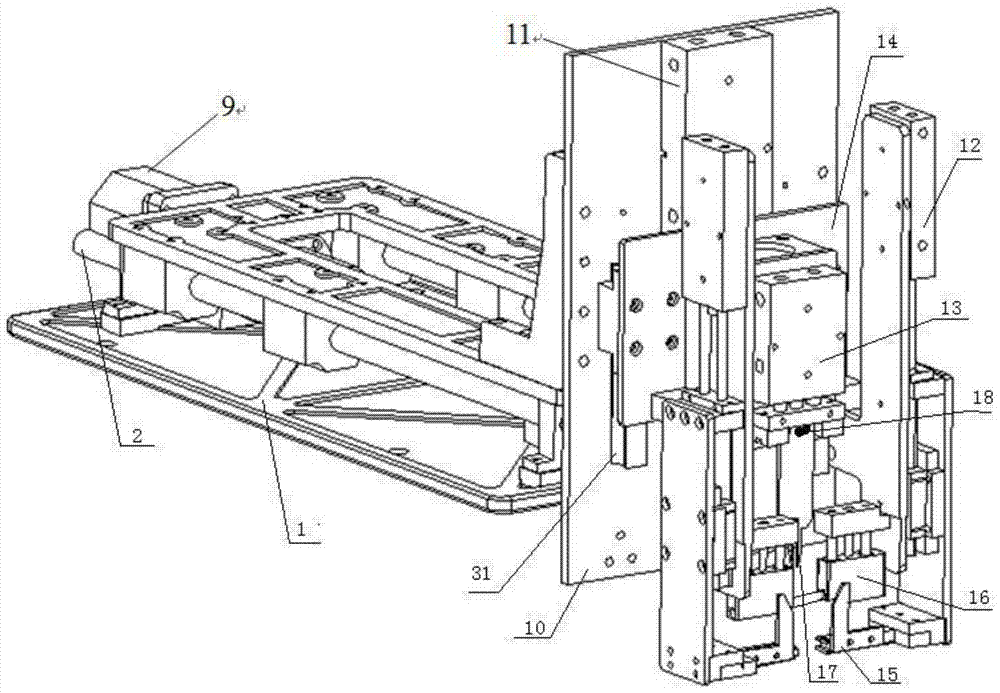

[0023] The threading device is composed of a threading device base (1), a T-shaped pallet (10), a threading motor (9), a clamping lifting cylinder (11), an upper and lower clamping cylinder (12), and a left and right clamping cylinder (13), the cylinder mounting plate (14), the downward stroke clamp (15), the upward stroke clamp (16) and the compass type branch fork (17); two polished rods are installed on the top of the thread stroke device base (1) (2) The polished rod (2) is placed horizontally, the threading motor (9) is installed on the base, and the screw screw is connected through the coupling. The screw nut is installed on the T-shaped pallet (10), and the T-shaped pallet ( 10) Placed on the polished rod (2), the threading motor (9) drives the screw screw, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com