Backwashing fluid filtering system

A fluid filter and backwashing technology, applied in the direction of filtration separation, gravity filter, fixed filter element filter, etc., can solve problems such as clogging the filter, affecting the operation of the fluid system, and reducing the flow rate through the filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

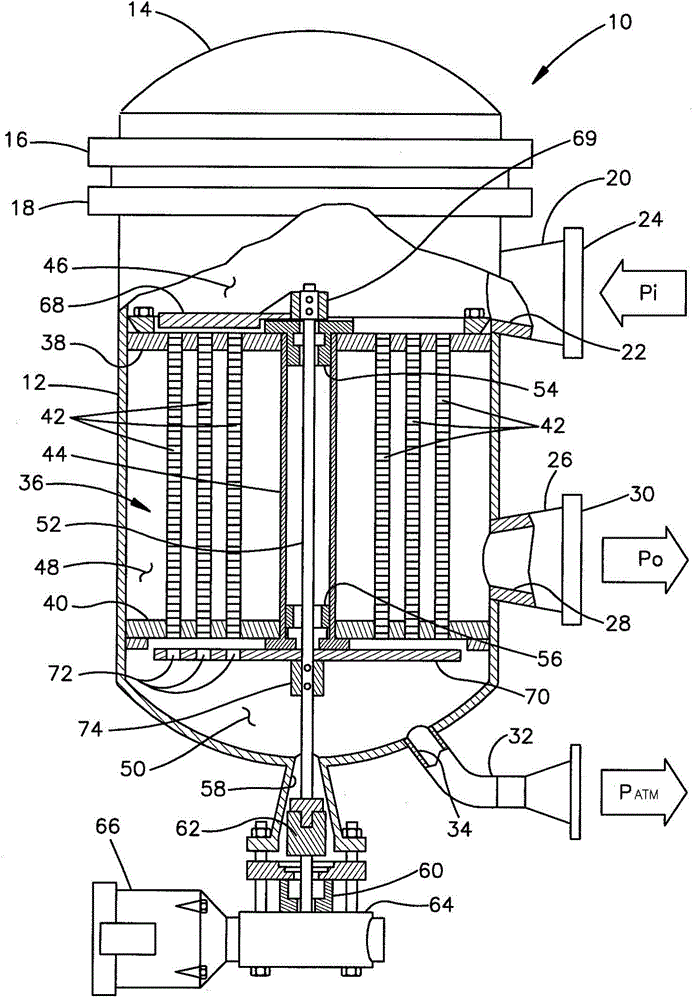

[0013] refer to figure 1 , one embodiment of the filtration system of the present invention is generally indicated at 10 and includes a pressure vessel having a wall 12 with a removable cover 14 fastened thereon by suitable means, such as surrounding the cover The annular flange 16 of the pressure vessel and the annular flange 18 on the pressure vessel are circumferentially arranged clips or bolts (not shown). The pressure vessel has an inlet connection 20 adjacent the flange 18 having an inlet passage 22 communicating with the interior of the pressure vessel and provided with an annular flange 24 adapted to connect to a supply that has been Pressurized to inlet pressure P i pipeline for fluid flow (not shown). The pressure vessel has provided thereon an outlet fitting 26 positioned adjacent the end of the vessel, away from the inlet 20, with an outlet passage 28 formed therein communicating with the interior of the vessel wall and having an annular flange disposed thereon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com