Lead-containing free-machining steel

A free-cutting steel, free technology, applied in the direction of metal rolling, etc., can solve the problem of not being able to obtain sufficient machinability, etc., and achieve the effect of excellent machinability

Active Publication Date: 2015-10-21

NIPPON STEEL CORP

View PDF8 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0011] However, in the case of lead-containing free-cutting steel, sufficient machinability may not be obtained simply by simply controlling the form of MnS inclusions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0114] Lead-containing free-cutting steels were manufactured under various chemical compositions and manufacturing conditions, and the machinability was evaluated.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

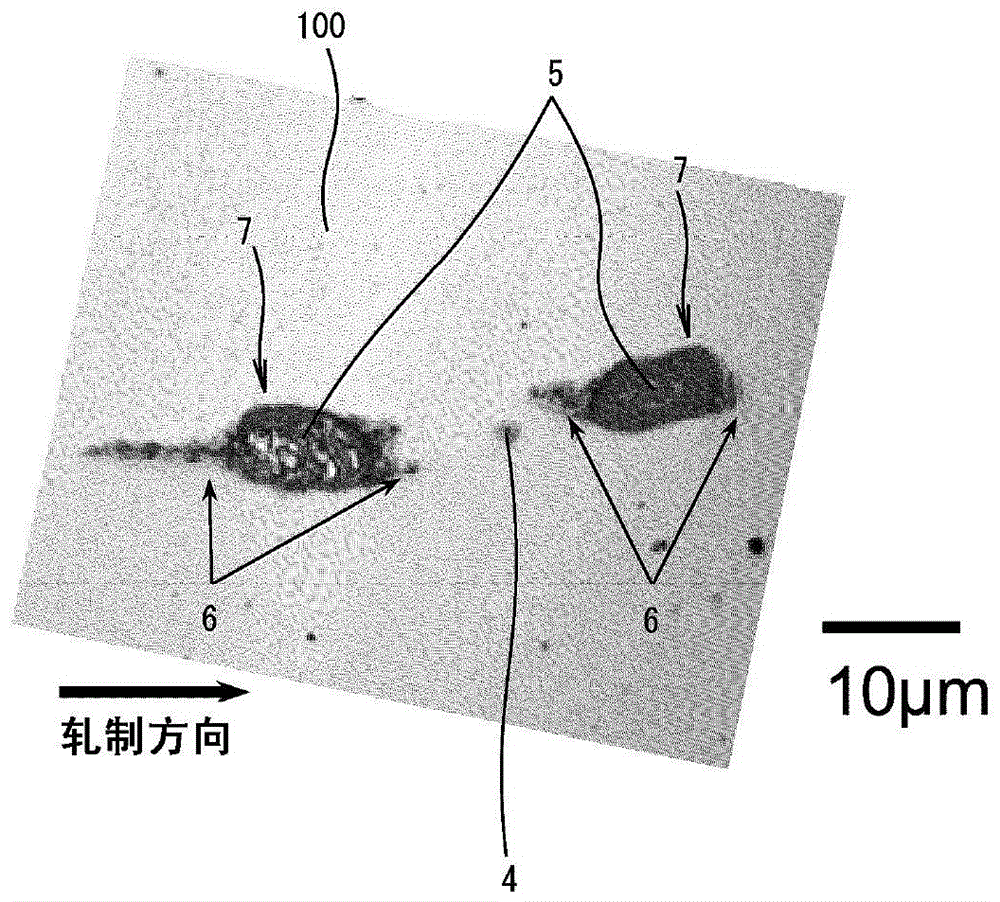

Provided is a lead-containing free-machining steel having excellent machinability. This lead-containing free-machining steel contains, in terms of mass%, 0.005-0.2% C, 0.3-2.0% Mn, 0.005-0.2% P, 0.01-0.7% S, 0.03-0.5% Pb, 0.004-0.02% N, and 0.003-0.03% O, with the remainder comprising Fe and impurities. The steel contains Pb inclusions (40) having a diameter of 0.01-0.5 μm in terms of equivalent-circle diameter, the number of the inclusions being 10,000 per mm2 or larger.

Description

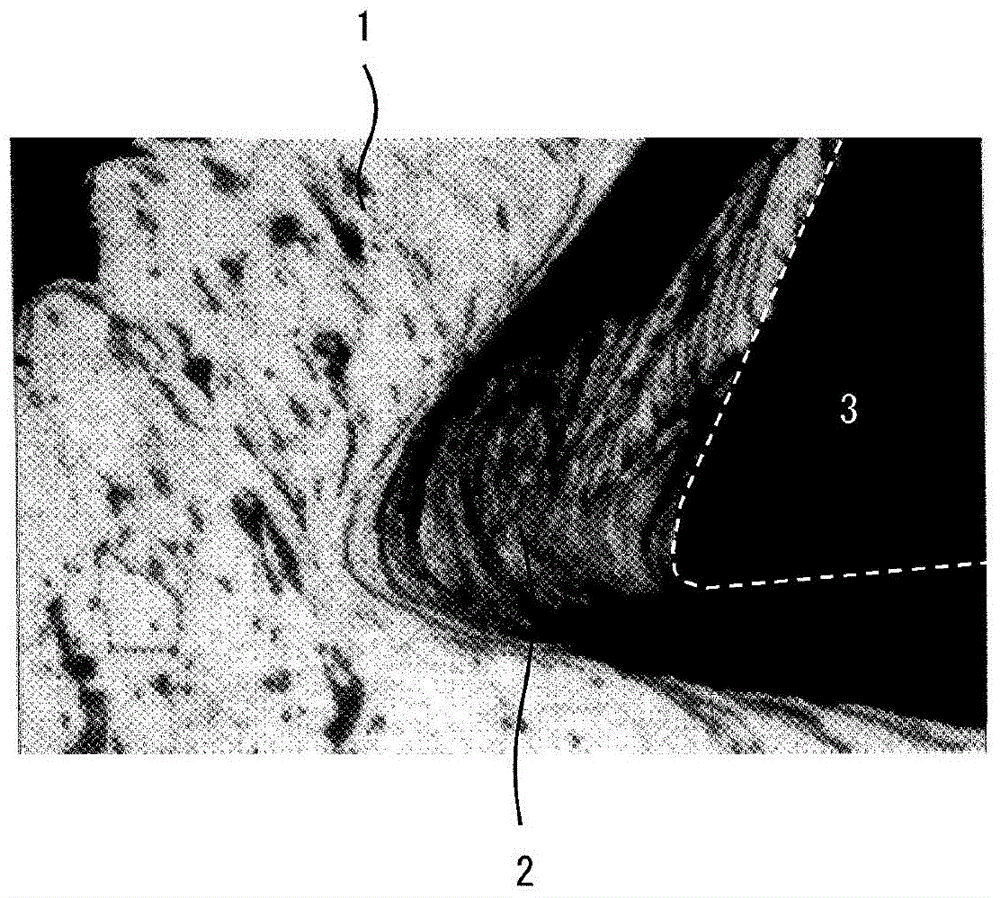

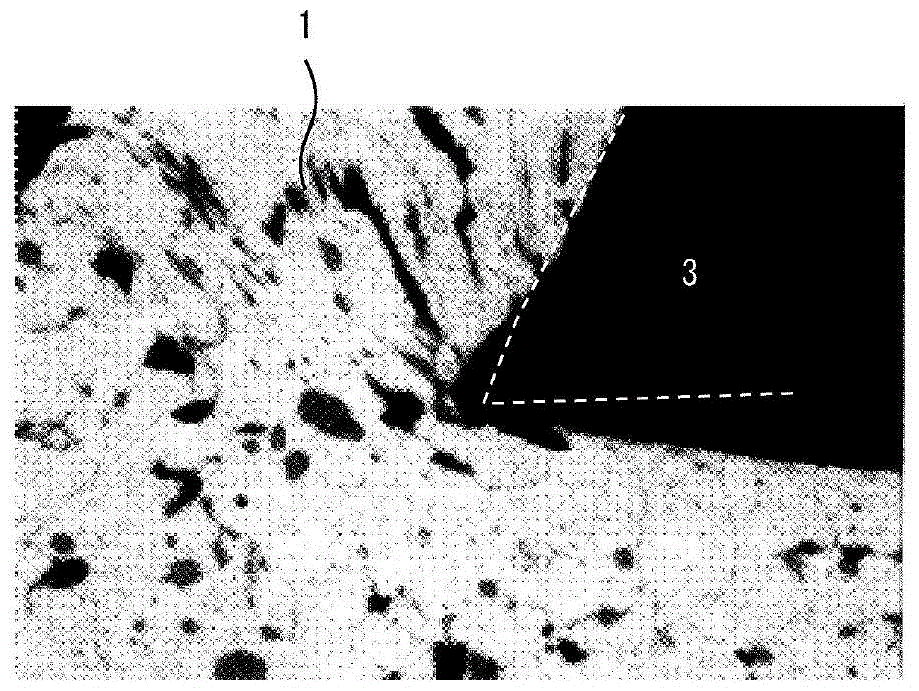

technical field [0001] The present invention relates to free-cutting steel, and more specifically, to lead-containing free-cutting steel containing lead. Background technique [0002] General mechanical products such as automobiles and electrical products consist of many parts. These components are mostly produced by machining. Therefore, "easy machinability", that is, excellent machinability is required for steel which is a raw material of parts. [0003] Free-cutting steel has excellent machinability. Typical free-cutting steels are, for example, SUM23 and SUM24L specified by JIS standards. Since Pb improves the machinability of steel, free-cutting steels often contain Pb. Hereinafter, free-cutting steel containing Pb is referred to as lead-containing free-cutting steel. [0004] In recent years, due to environmental considerations, free-cutting steels with suppressed Pb content and Pb-free free-cutting steels that do not contain Pb have been proposed. However, lead-...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/00C22C38/60B21B3/02B22D27/04C21D8/00

CPCC22C38/00B21B3/02B22D27/04C21D8/00C21D8/0247C21D2211/004C21D2261/00C22C38/60C22C38/001C22C38/002C22C38/008C22C38/04C22C38/08C22C38/12C22C38/16C22C38/18

Inventor 桥村雅之渡里宏二

Owner NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com