Connecting structure for drawer basket and slide rails

A connecting structure and sliding rail technology, which is applied to furniture parts, household appliances, drawers, etc., can solve the problems of complex structure of locking adjustment mechanism, can not meet the needs of use, can not be used for drawer pull baskets, etc., to improve the neatness and Aesthetics, simple and reasonable structure, quick disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

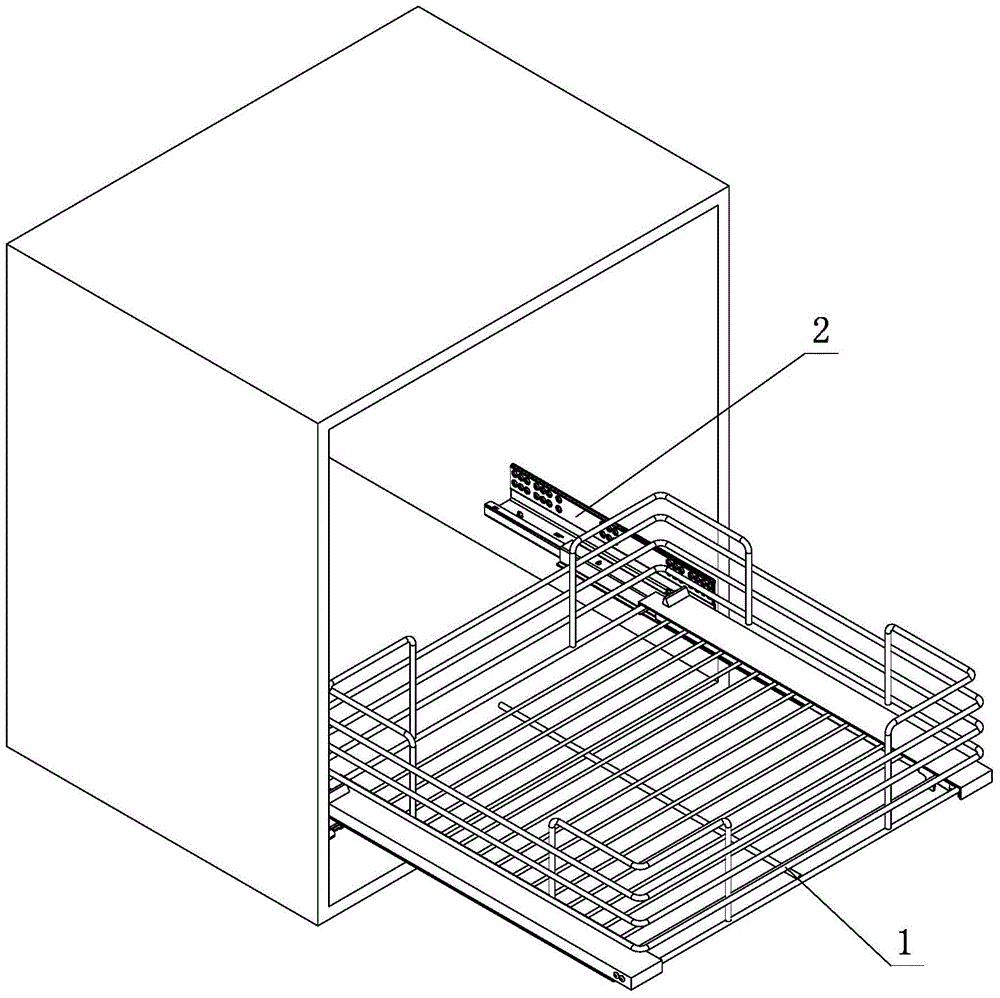

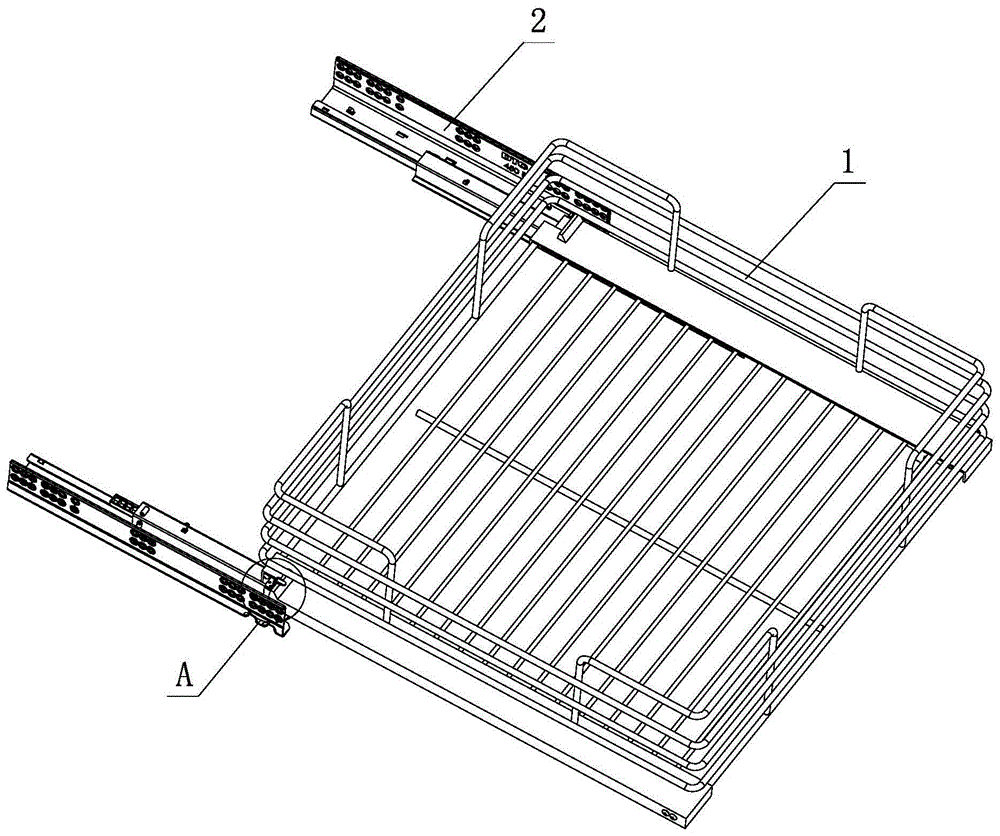

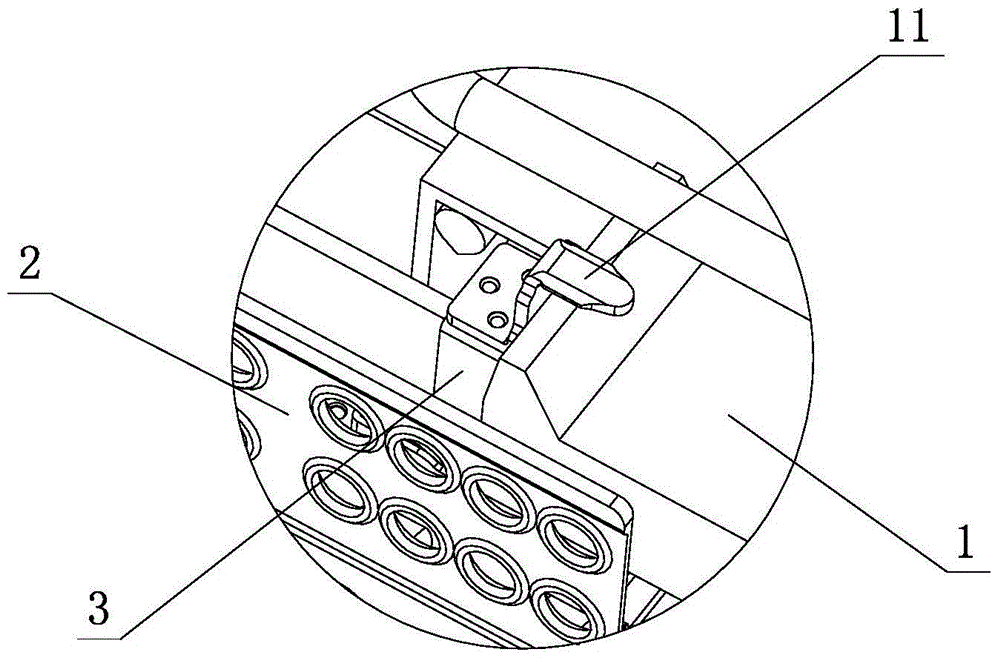

[0026] see Figure 1-Figure 7 , the connection structure between the pull basket and the slide rail, including the pull basket 1, the fixed slide rail 2 and the pull-out rail 3 slidably arranged on the fixed slide rail 2, the pull basket 1 is detachably arranged on the pull-out rail 3, and the pull The front end of the basket 1 and / or the pull-out rail 3 is provided with a front connecting device, and the front connecting device includes a positioning unit 4.1, a clamping unit 4.2 and an adjustment assembly; wherein, the positioning unit 4.1 is inserted on the pull-out rail 3, and at least realizes The left and right limit of the two, the clamping unit 4.2 is fastened on the pull-out rail 3, and at least realizes the front and rear limit of the two, the pull basket 1 is supported on the pull-out rail 3, and the fastening unit 10 and the adjustment assembly Fix each other, and at least realize the upper and lower limit of the pull basket 1 relative to the adjustment component a...

no. 2 example

[0036] see Figure 8 , Figure 9 , the connection structure between the basket and the slide rail is different from the first embodiment in that: the adjustment assembly includes a push element 5 and an adjustment element; wherein, the push element 5 is provided with a grille part 5.3, and is slidably arranged on a fixed On the chute 4.3 of the element 4, the adjusting element is an adjusting dial 8, and one end is rotated and positioned on the fixed element 4, and cooperates with the grille part 5.3, and the other end is provided with an action part 6 for tools or manual action, through the tool Or manually drive the action part 6, adjust the rotation of the turntable 8, and drive the grille part 5.3, so that the pushing element 5 can move linearly and laterally from side to side relative to the fixed element 4, so as to realize that the pulling basket 1 is facing the front connecting device and / or can pull out the rail 3 Left and right horizontal position adjustment.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com