Volatile gas collecting device

A technology of volatile gas and collection equipment, which is applied in the directions of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc. Drying, promotes drying of the fabric, and promotes the effect of air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

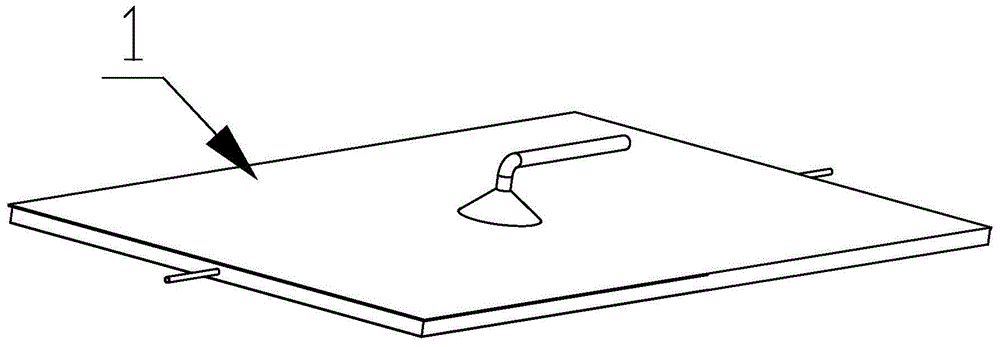

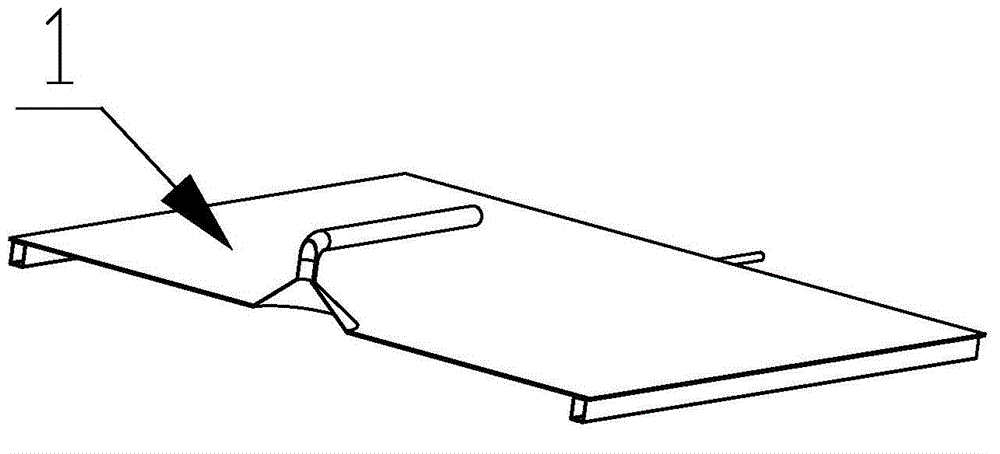

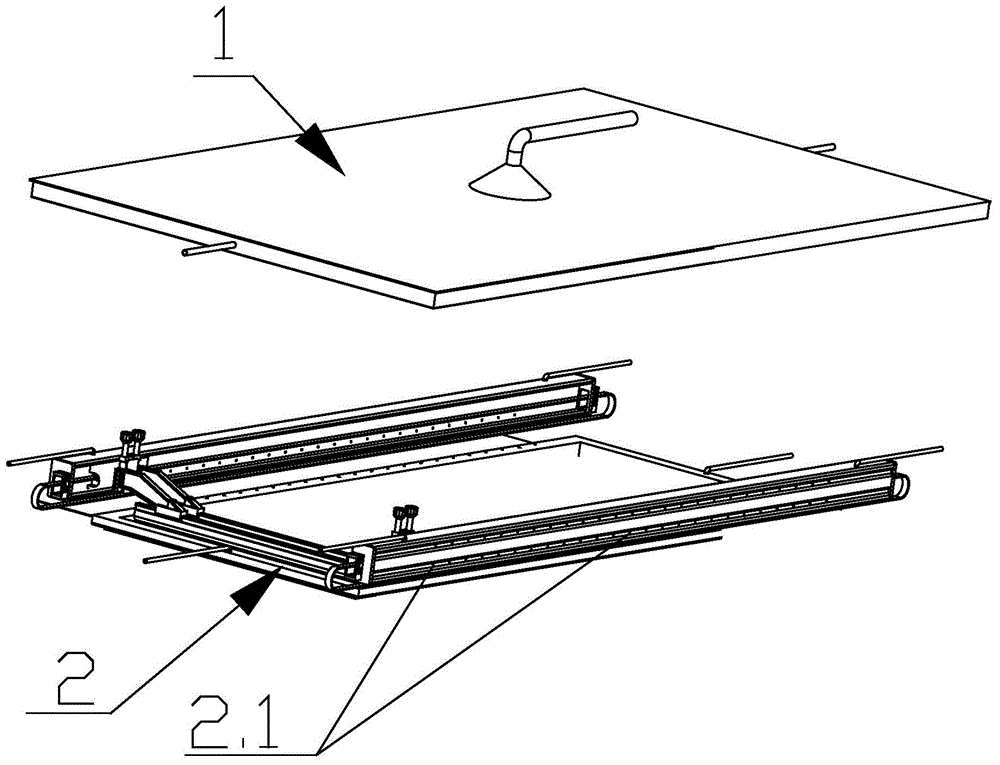

[0022] refer to Figure 1-Figure 3 A volatile gas collection device is shown, which includes a gas collection cover 1, on which an air suction device is arranged, and the lower surface of the gas collection cover 1 forms an air suction area.

[0023] The air blowing assembly is provided on the gas collection hood 1, and the air blowing assembly makes the air flow blow out from around the gas collection hood 1 downwards, and forms a closed ring-shaped air wall. The periphery of the gas collection cover 1 is designed to be hollow, and then the gas is blown into the hollow through the blowing assembly, and then blown out from the bottom of the gas collection cover 1 to form a closed ring-shaped gas wall. The closed ring air wall can control the volatilized gas in the closed area formed by the air wall to avoid the leakage of volatile gas.

[0024] A ring-shaped air outlet hole is opened downward around the gas collection cover 1, and the air outlet hole communicates with the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com