Auxiliary airplane engine installing system

An aircraft engine and installation system technology, which is applied to aircraft parts, assembly machines, transportation and packaging, etc., can solve problems such as mutual friction and extrusion, low degree of automation, and no guarantee of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

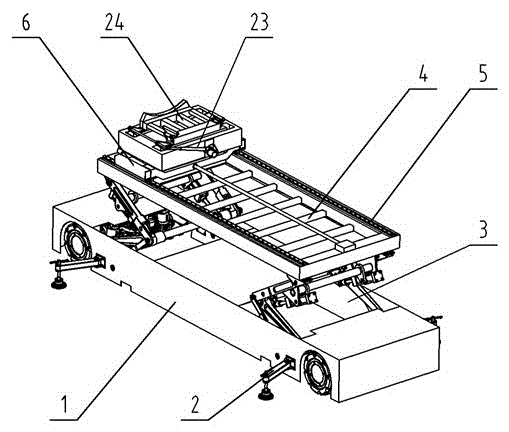

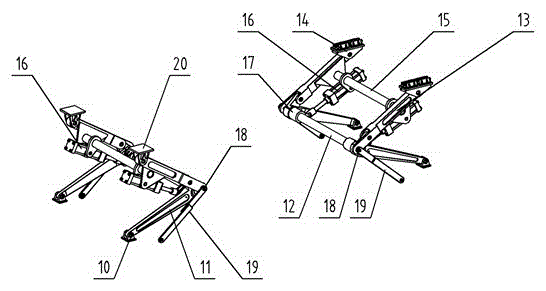

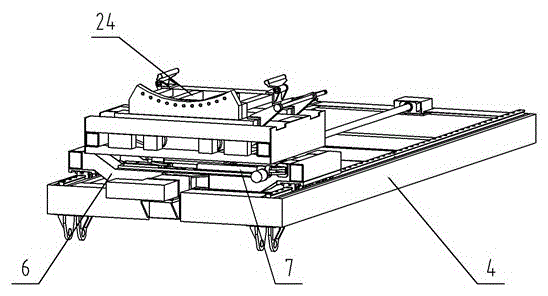

[0015] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 5 Shown: an aircraft engine auxiliary installation system, which includes a car body 1, at least two pairs of outrigger assemblies 2 are evenly distributed on the car body 1, and lifting mechanisms 3 are symmetrically arranged at both ends of the car body 1 in the axial direction , the tops of these two sets of lifting mechanisms 3 jointly support the X-axis translation frame 4, X-axis slideways 5 are arranged on both sides of the X-axis translation frame 4, and a Y-axis slideway 5 is slidingly connected to the X-axis slideway 5. Axis translation frame 6, and matching with Y-axis translation frame 6 is provided with motor and ball screw transmission pair, on Y-axis translation frame 6, then is slidably connected with moving frame 8 driven by Y-axis electric push rod 7, in The moving frame 8 is provided with a C-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com