Marking press for corrugated paper

An indentation machine and corrugated paper technology, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of indentation tearing, weak pressure, low forming efficiency, etc., to ensure the degree of wetting and indentation depth. Controllable, various effects of indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

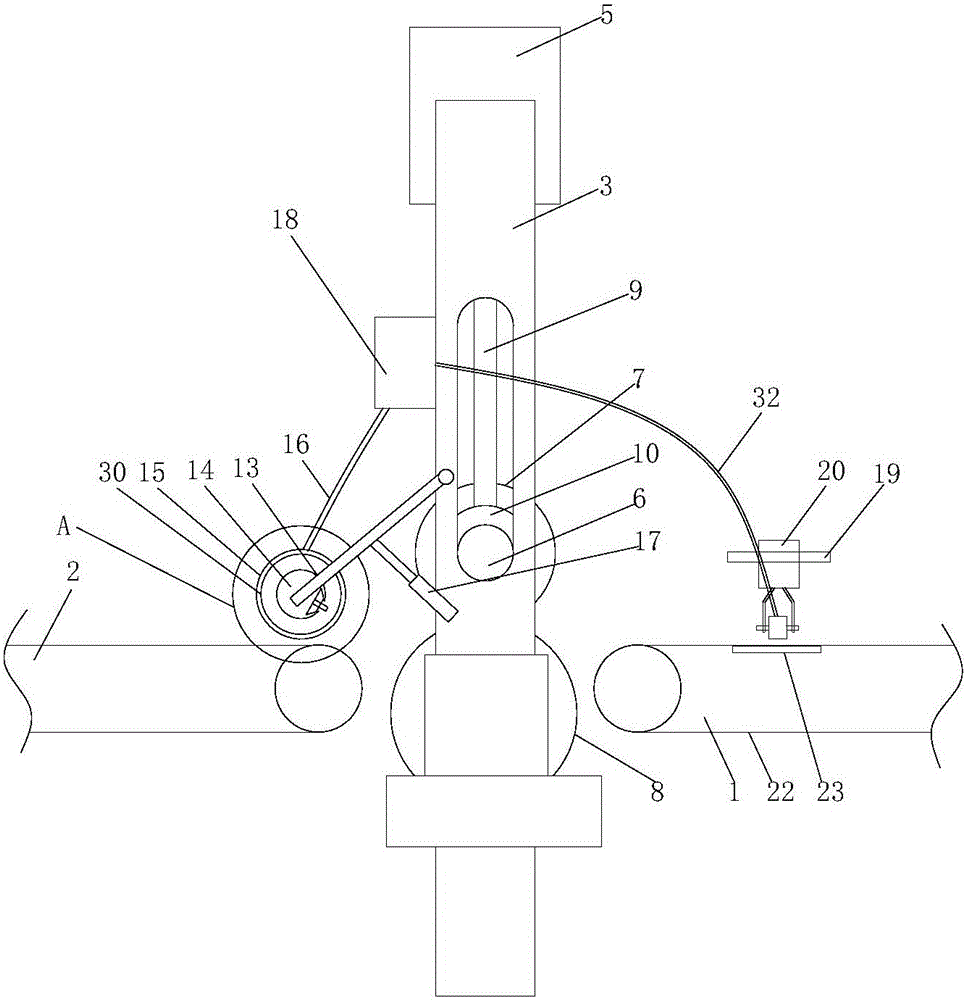

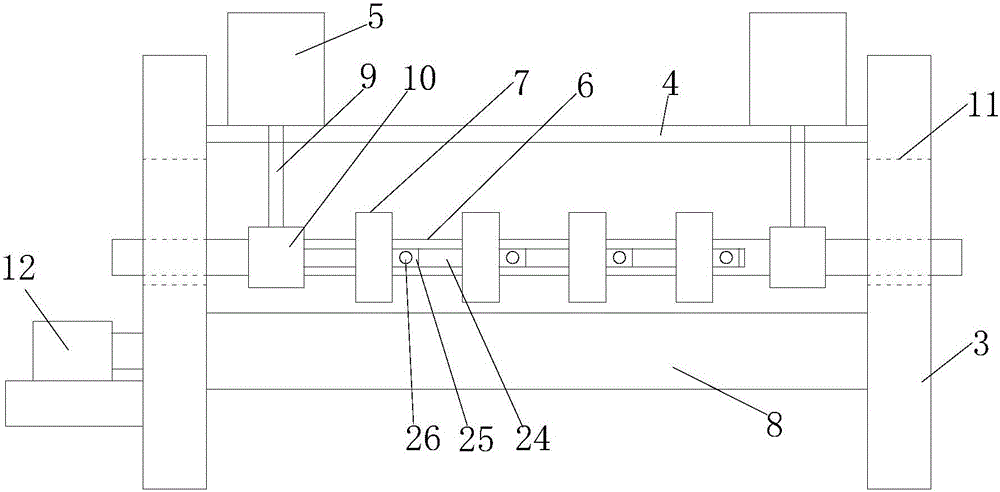

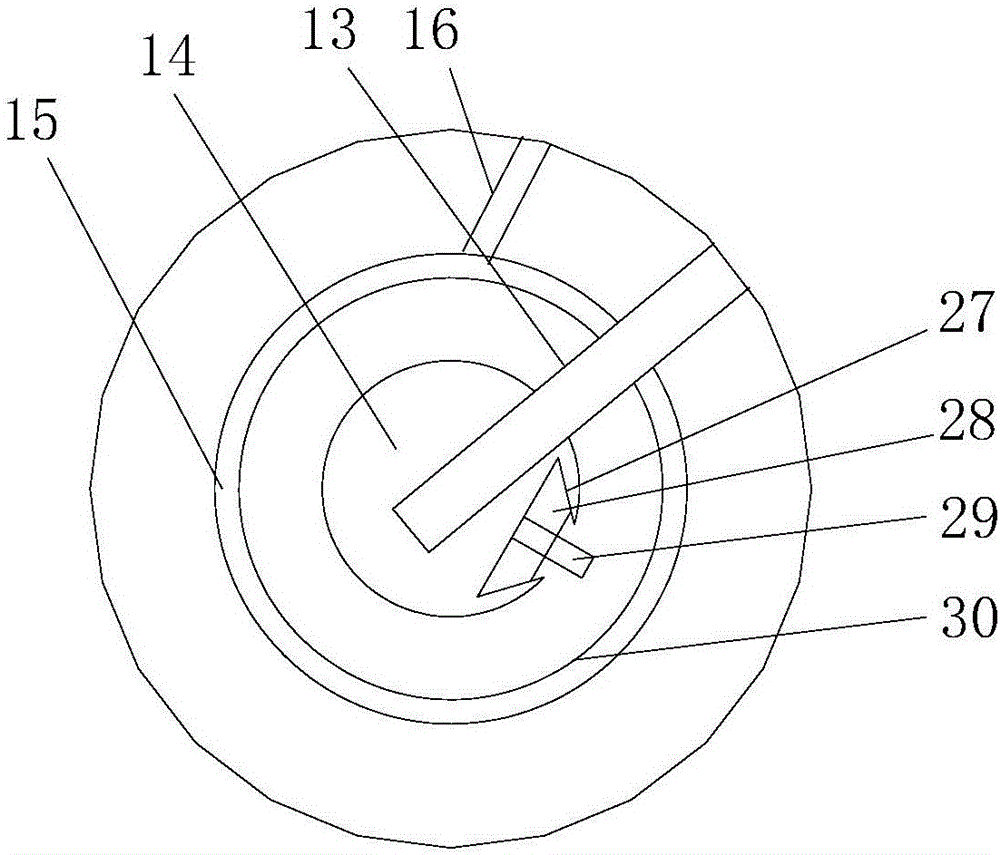

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 as shown, figure 1 It is a structural schematic diagram of a creasing machine for corrugated paper proposed by the present invention; figure 2 It is a structural schematic diagram of a longitudinal creasing device in a creasing machine for corrugated paper proposed by the present invention; image 3 It is a structural schematic diagram of the enlarged schematic diagram of part A in a creasing machine for corrugated paper proposed by the present invention; Figure 4 It is a structural schematic diagram of a transverse creasing device in a creasing machine for corrugated paper proposed by the present invention.

[0024] refer to figure 1 , figure 2 , a creasing machine for corrugated paper proposed by the present invention, including a longitudinal creasing device, a pre-pressing wetting device, a front conveying device 1 and a rear conveying device 2, and the longitudinal creasing device is arranged on the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com