Aerial work platform with easily-operated platform locking structure

A high-altitude work platform and locking structure technology, applied in the direction of lifting devices, lifting equipment safety devices, etc., can solve the problems of low assembly efficiency, low operation efficiency, negative impact of tire walking, etc., to achieve easy maintenance, easy loading and unloading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

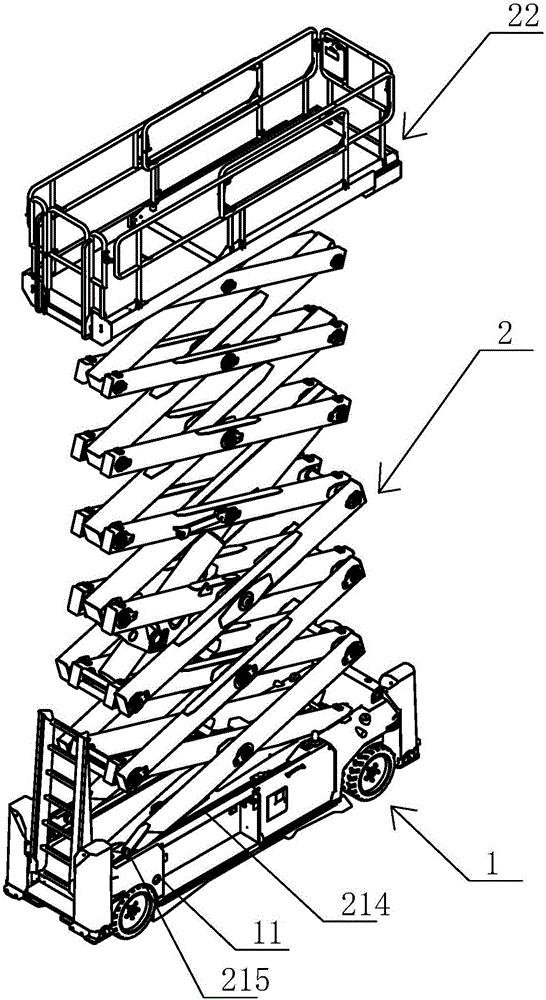

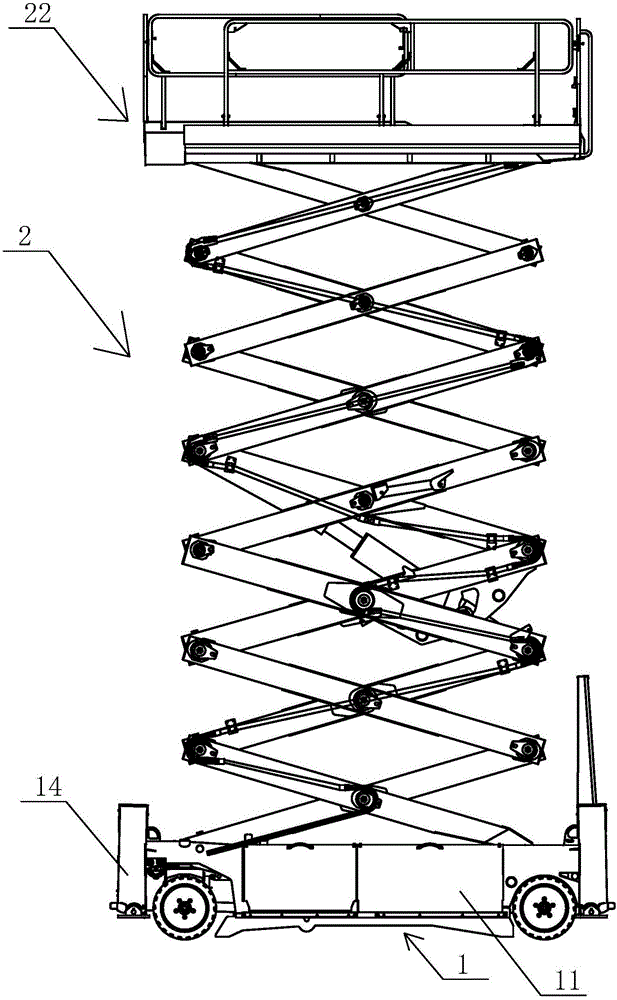

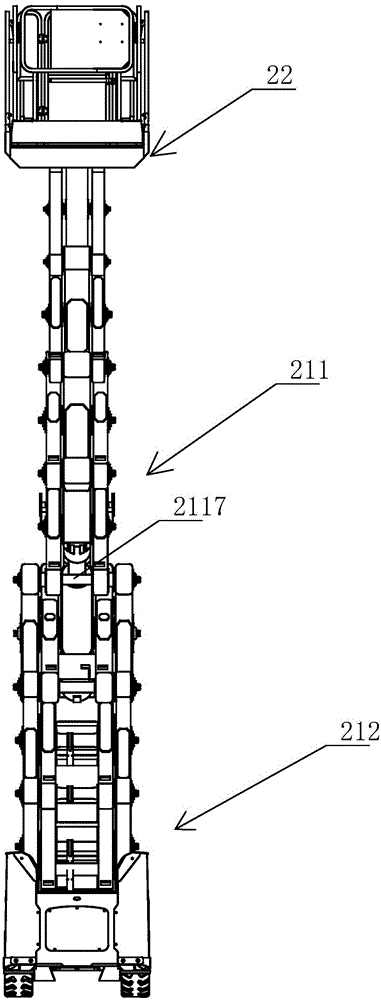

[0036] see Figure 1-Figure 22The scissor-type aerial work platform in this embodiment includes a traveling chassis 1 and a lifting device 2, the traveling chassis 1 includes a chassis 11, a traveling device 12, a pothole protection mechanism 13 and a leg structure 14, and the traveling device 12 includes Left steering wheel 121, right steering wheel 122, left wheel frame 123, right wheel frame 124, linkage frame 125, steering oil cylinder 126 and turning to bent plate 127, described left steering wheel 121, right steering wheel 122 are respectively rotated and installed on left wheel frame 123 1. On the right wheel frame 124, the left steering wheel 121 and the right steering wheel 122 are respectively driven by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com