A pole for assembling transmission towers

A technology for transmission towers and poles, which is applied in the direction of towers, building types, buildings, etc., can solve the problems of FRP that cannot be used for a long time, poor aging resistance, and low elastic modulus, so as to facilitate production and on-site handling, reduce impact, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

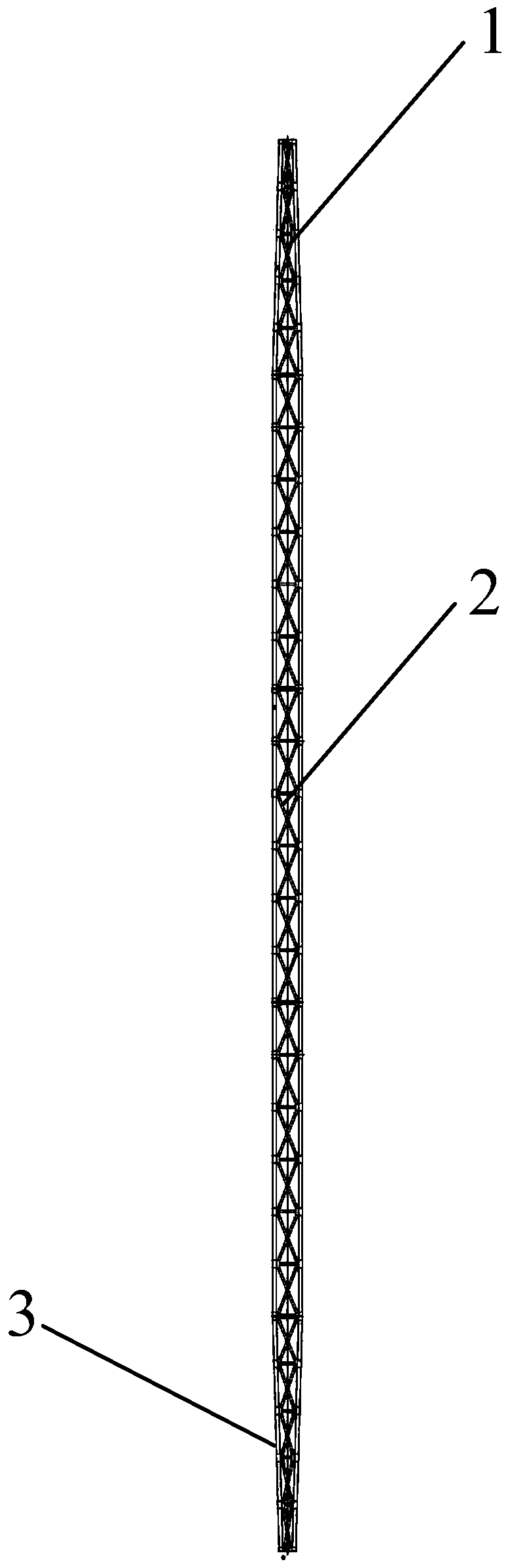

[0063] Embodiment 1: as Figure 8 As shown, a pole for assembling a power transmission tower, the power transmission tower includes a vertically arranged tower body 15 and a cross arm 16 horizontally arranged on the tower body 15, as figure 1 As shown, the pole is composed of an upper end section 1, a standard section 2 and a lower end section 3 arranged sequentially from top to bottom, and the pole is provided with a stay wire 18 connected to the transmission tower;

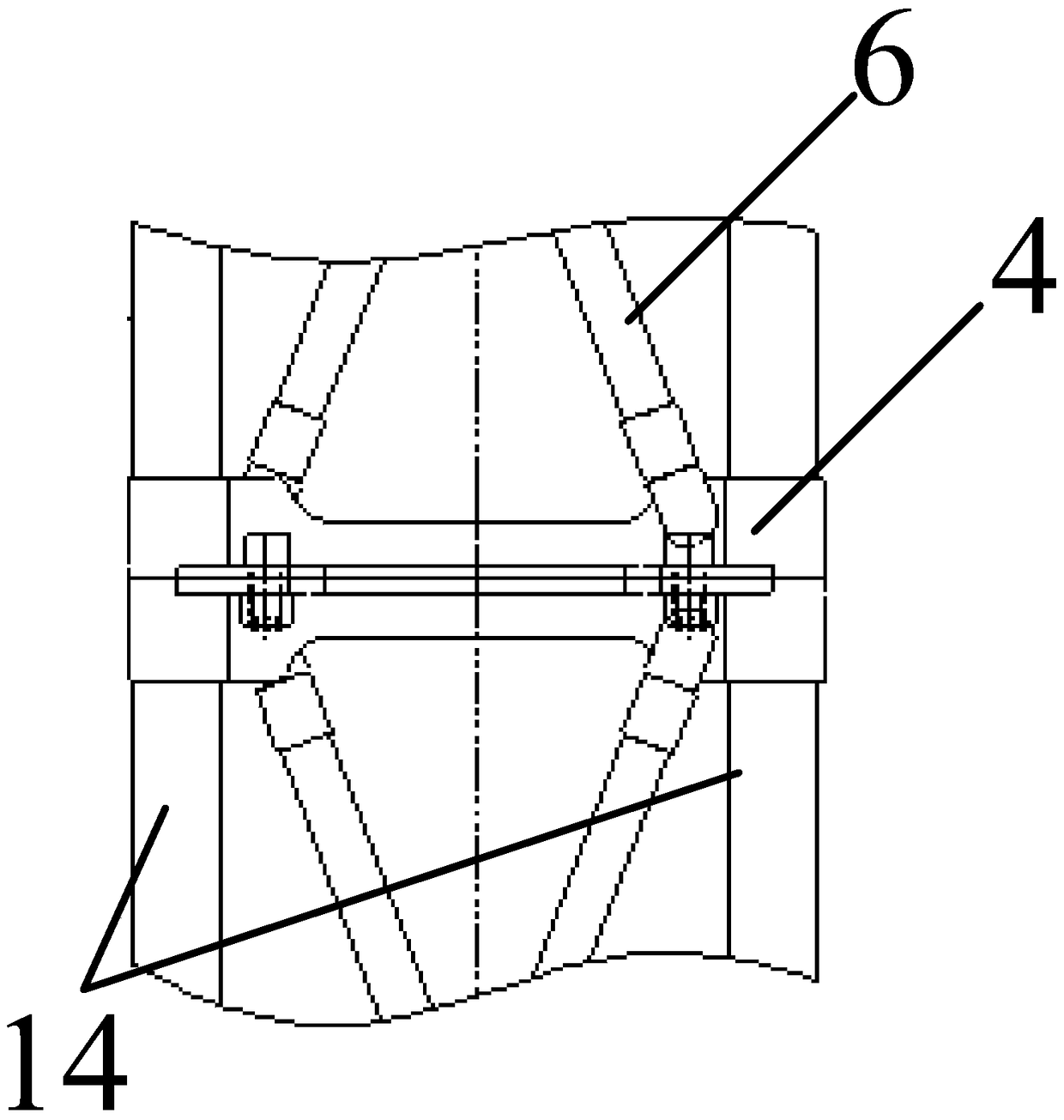

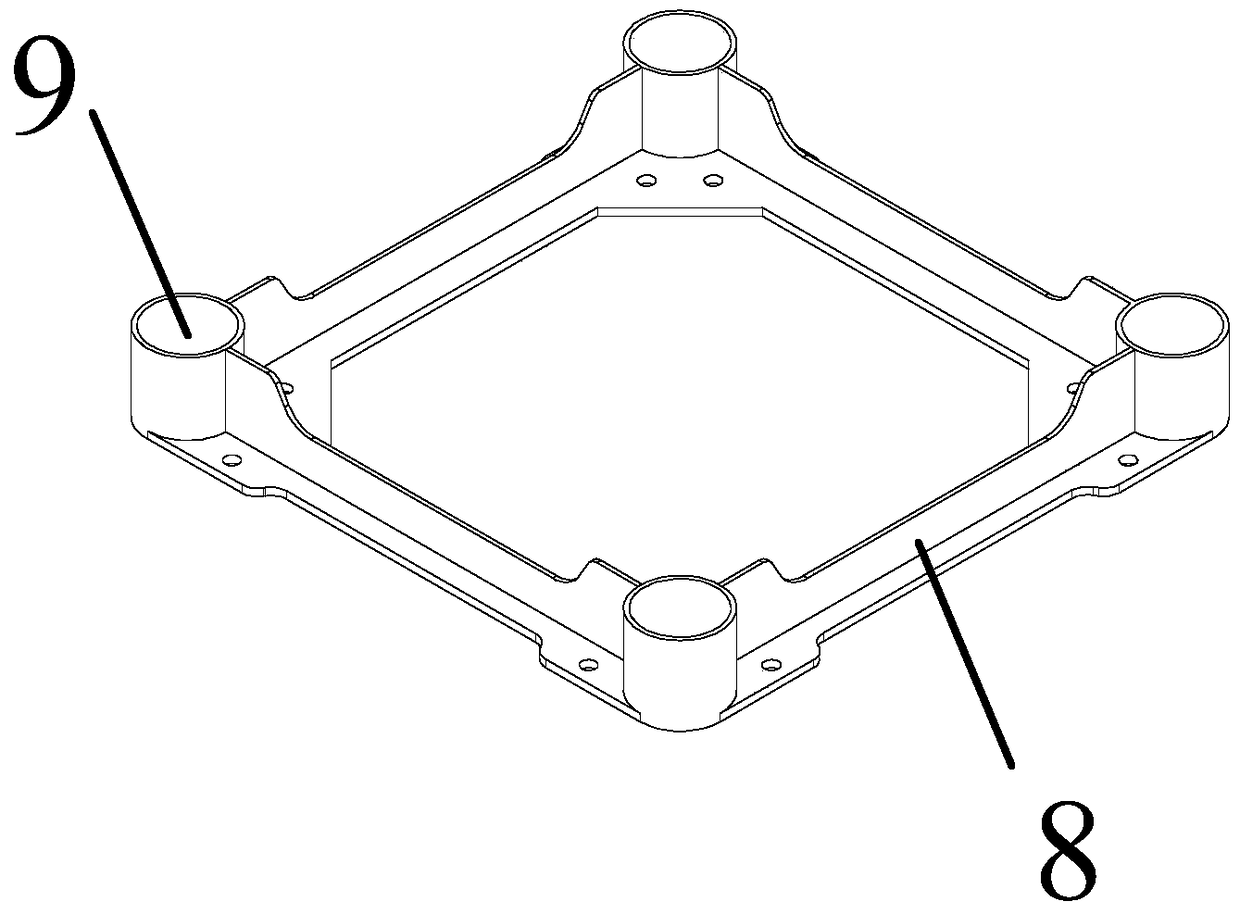

[0064] Such as figure 2 , image 3 and Figure 4 As shown, the upper end section 1, the standard section 2 and the lower end section 3 are connected by a rectangular connector 4, and the section body of the standard section 2 is adjacent to the main pipe 14 arranged vertically. A rectangular frame composed of inclined tubes 6;

[0065] Such as Figure 10 As shown, the stay wire 18 extends from the pole top to the tower body, and is supported by the struts 5 arranged horizontally on the transmission tower. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com