Cascaded water chilling unit for dual purposes of intermediate temperature and low temperature

A chiller, cascading technology, applied in the direction of refrigerators, refrigeration components, compressors with cascading work, etc., can solve the problems that cannot meet the production requirements of high efficiency, energy saving, and environmental protection, cannot produce chilled water, and idle equipment High efficiency and other problems, to achieve the effect of reducing equipment occupation, improving stability, and stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

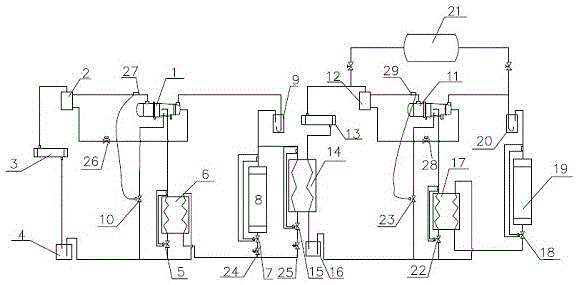

[0039] Such as figure 1 It is a dual-purpose cascade chiller for medium temperature and low temperature. The cascade chiller includes a high-temperature stage system, a low-temperature stage system, and a control system. The high-temperature stage system is connected to the low-temperature stage system by an intermediate heat exchanger 14 , and the high-temperature stage system is connected in sequence by a high-temperature stage compressor 1 , a high-temperature stage condenser 3 and a high-temperature stage evaporator 8 to form a loop. Both ends of the high-temperature stage evaporator 8 are connected in parallel with intermediate heat exchangers 14, and the low-temperature stage system consists of a low-temperature stage compressor 11, a low-temperature stage condenser 13, an intermediate heat exchanger 14, and a low-temperature stage evaporator 19 to form a loop in sequence . Wherein, the liquid inlet end of the high-temperature stage evaporator 8 is provided with a therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com