A leadless festive cannon and its manufacturing process

A production process, lead-free technology, applied in firecrackers, fireworks, offensive equipment and other directions, can solve the problems of difficult product quality control, high safety hazards, high cost and high cost, and achieve stable product form, tight and firm connection, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below, the present invention will be described in more detail with reference to the drawings and specific embodiments.

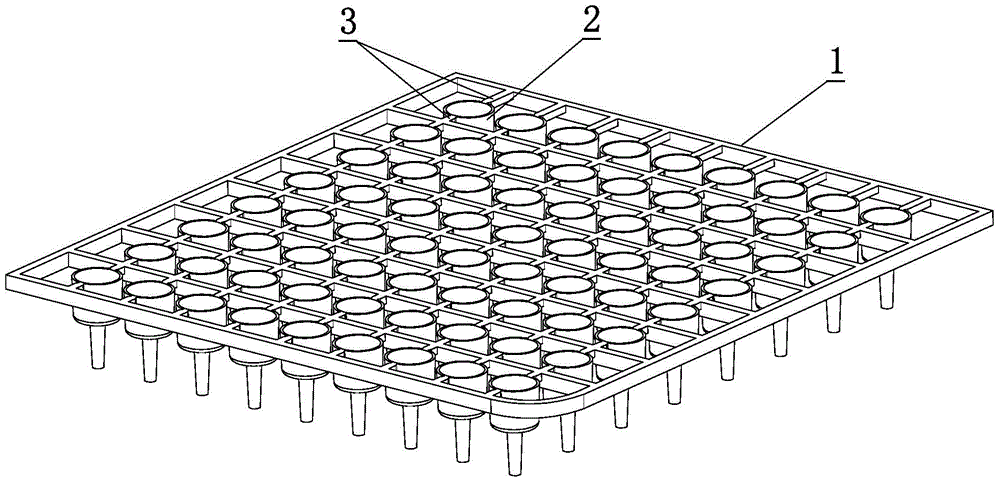

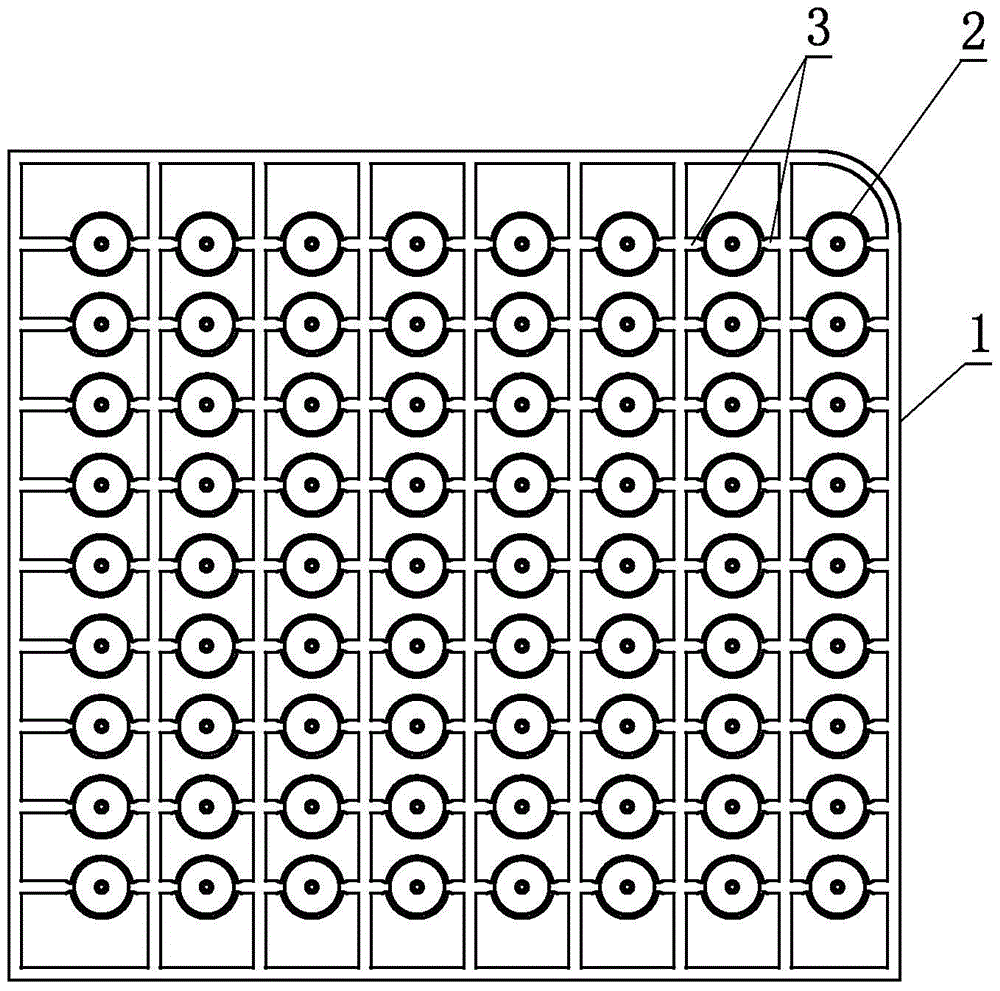

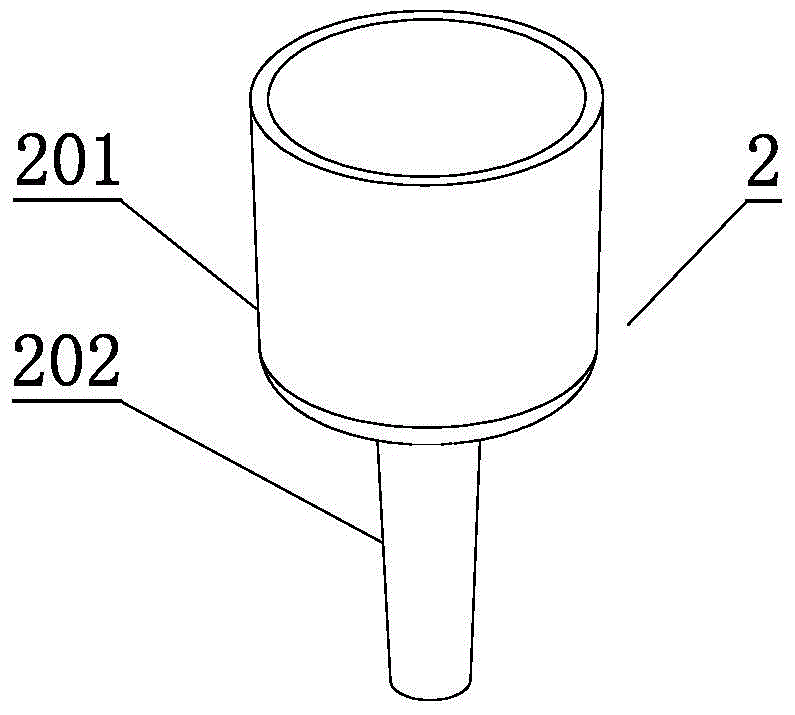

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, its composition is composed of a connecting frame 1, a single body with a tailpipe 2, a connecting bar 3, an upper pipe body 201 with a bottom, a fuel tailpipe 202, a fire guide hole 203, and an ignition port 204.

[0039] The structural features of specific embodiments are:

[0040] A leadless festive cannon, characterized in that it includes a conjoined frame 1, a unit with a tailpipe 2, and a connecting bar 3, and a plurality of said units with a tailpipe 2 are arbitrarily connected to the conjoined frame 1 through the connecting bar 3 Arrange and combine to form a conjoined structure as a whole plate, in which,

[0041] The tail pipe unit 2 further includes an upper pipe body 201 with a bottom, and a fuel tail pipe 202 which is arranged below the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com