Carbon fiber composite rod used on intelligent steel strand and preparation method

An intelligent steel strand and carbon fiber technology, applied in the direction of fiber mechanical structure, structural elements, building components, etc., can solve problems such as endangering building safety, reducing bearing stress, and inability to monitor changes in tensile stress of steel strands. Safe to use, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

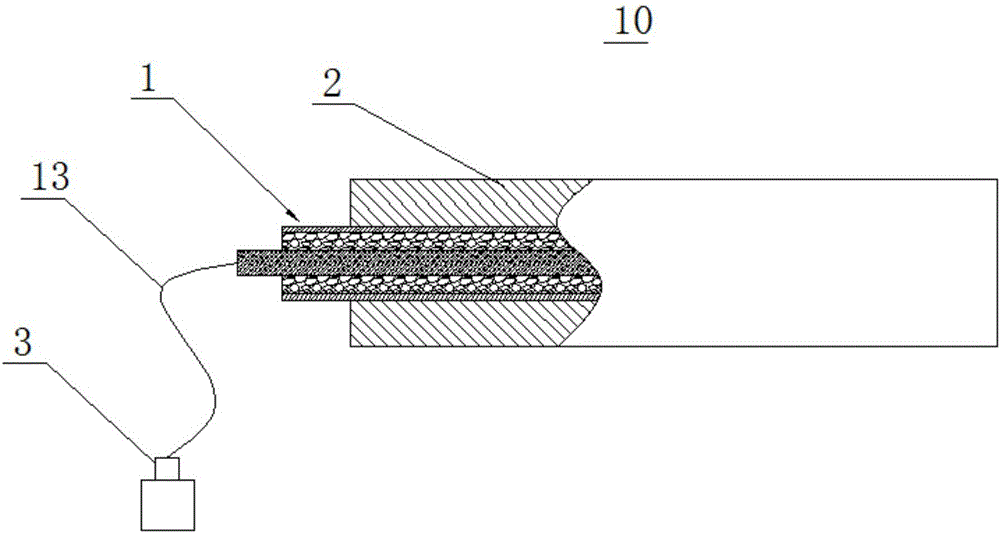

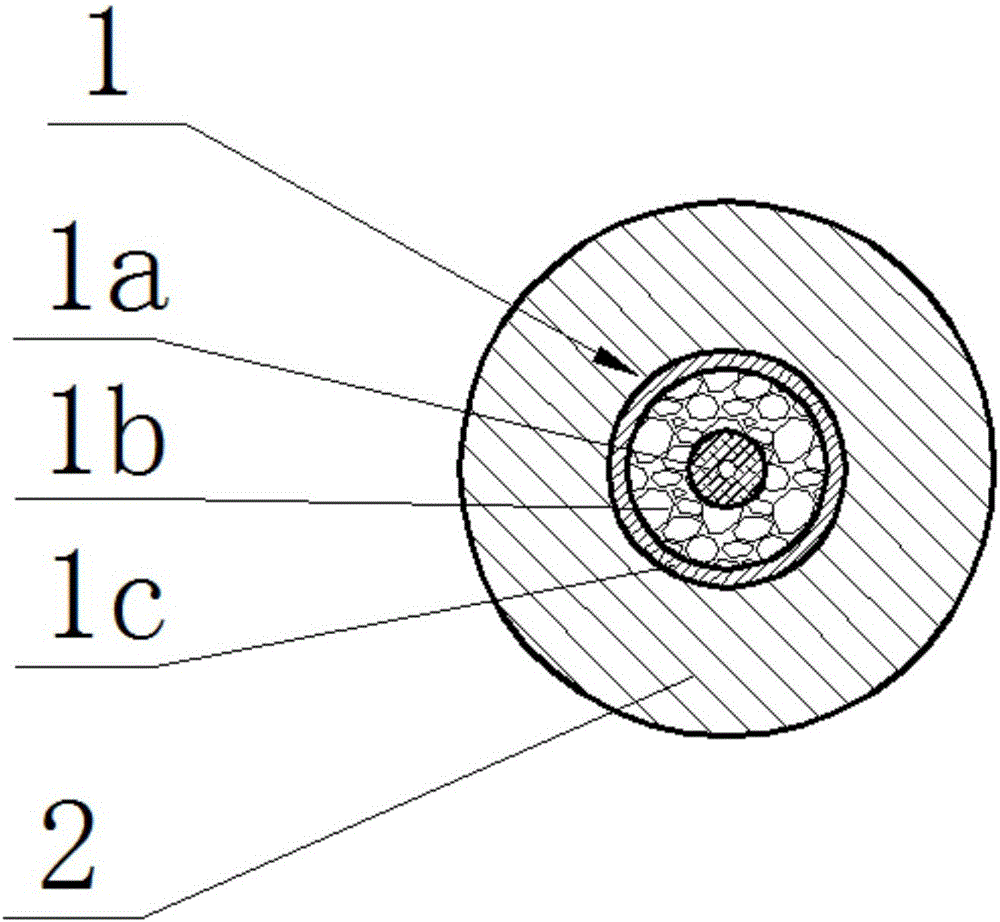

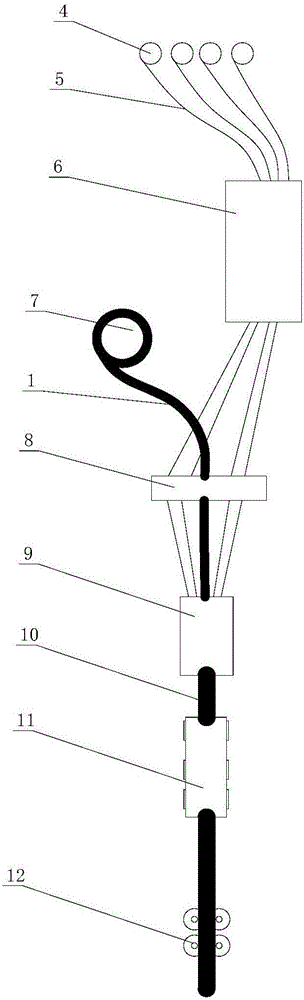

[0019] The present invention provides a carbon fiber composite rod used on smart steel strands. The carbon fiber composite rod 10 includes: an optical fiber 1, and a composite carbon fiber 2 is arranged outside the optical fiber 1; the composite carbon fiber 2 is made of adhesive resin and additives. It is composed of a plurality of carbon fiber bundles 5 .

[0020] The ratio of the resin and the additive is: resin: additive=9:1; the resin includes: thermosetting resin or thermoplastic resin; the additive includes: toughening agent, accelerator and coupling agent, wherein the toughening agent: Accelerator: coupling agent = 5:2:3.

[0021] The optical fiber 1 includes: a purple-coated optical fiber 1a, a strain sensing ointment 1b is arranged outside the purple-coated optical fiber 1a, and an aramid protective layer 1c is arranged outside the strain sens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com