Waterproof flexible cable

A technology of flexible cables and waterproof layers, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of frequent crossing of cable bending stress and torsional stress, affecting the service life of cables, and too small bending radius, etc., to achieve convenience The effect of compressing transportation, prolonging service life and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

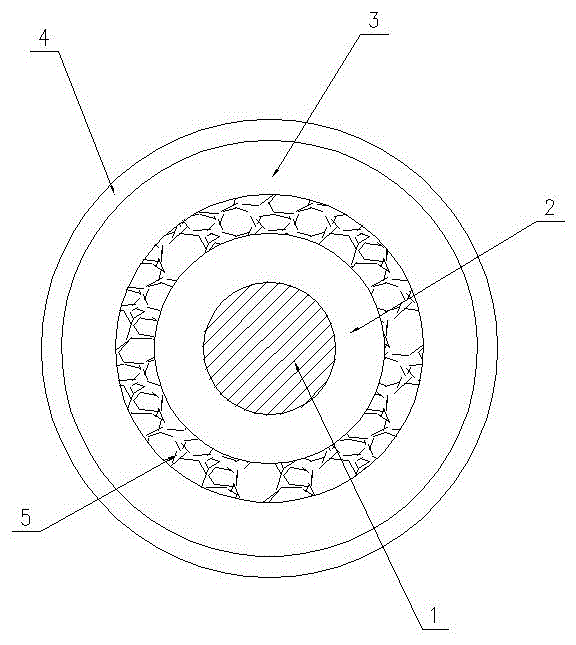

[0015] As shown in the figure, in order to achieve the above purpose, the technical solution adopted by the present invention is: a waterproof flexible cable, which is characterized in that: the core 1 is sequentially composed of an insulating layer 2, a waterproof layer 3, and a protective cover 4 from the inside to the outside. Composed, the water-absorbing layer 5 is provided between the waterproof layer 3 and the insulating layer 2; the water-absorbing layer 5 evenly covers the surface of the insulating layer 2, and the water-absorbing layer 5 is closely bonded to the insulating layer 2; the protective cover 4 and the waterproof layer 3 are connected as a whole through extrusion.

[0016] Preferably, the material of the waterproof layer 3 is plastic-coated aluminum alloy, and the waterproof layer 3 is closely attached to the water-absorbing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com