igto package structure

A packaging structure and ring structure technology, applied in the direction of output power conversion devices, electrical components, etc., can solve the problems of waveform distortion and noise, increase in volume and weight, and reduce efficiency, and achieve large connection contact area, which is conducive to heat conduction, Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0025] The IGTO packaging structure proposed by the present invention includes a GTO device 1, a driving circuit board 2, a conductive substrate 3 and a protective cover 4;

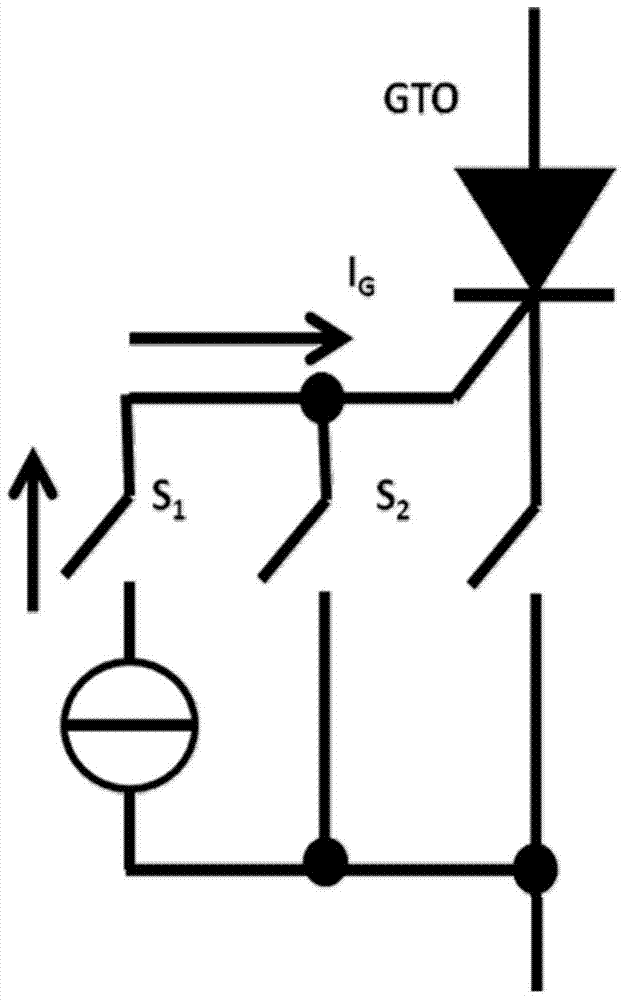

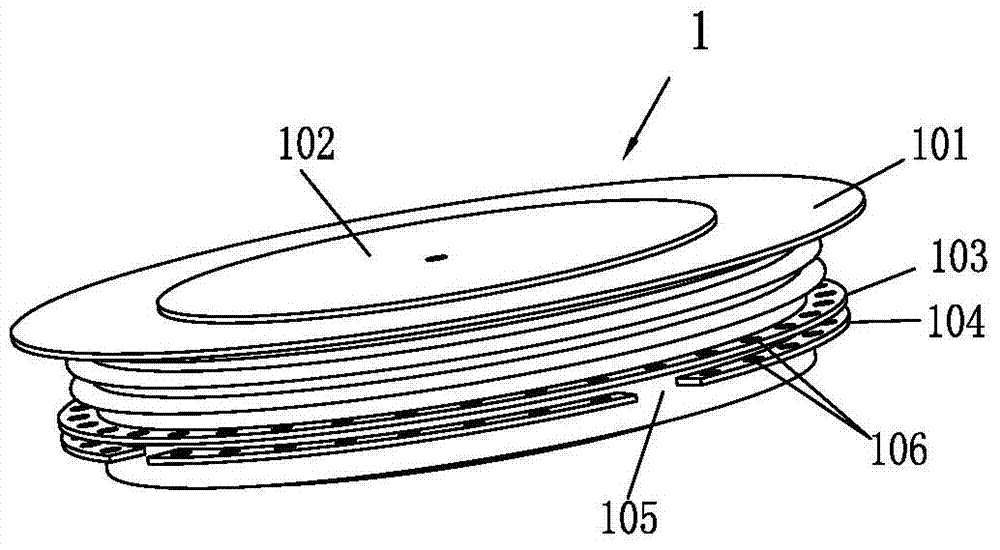

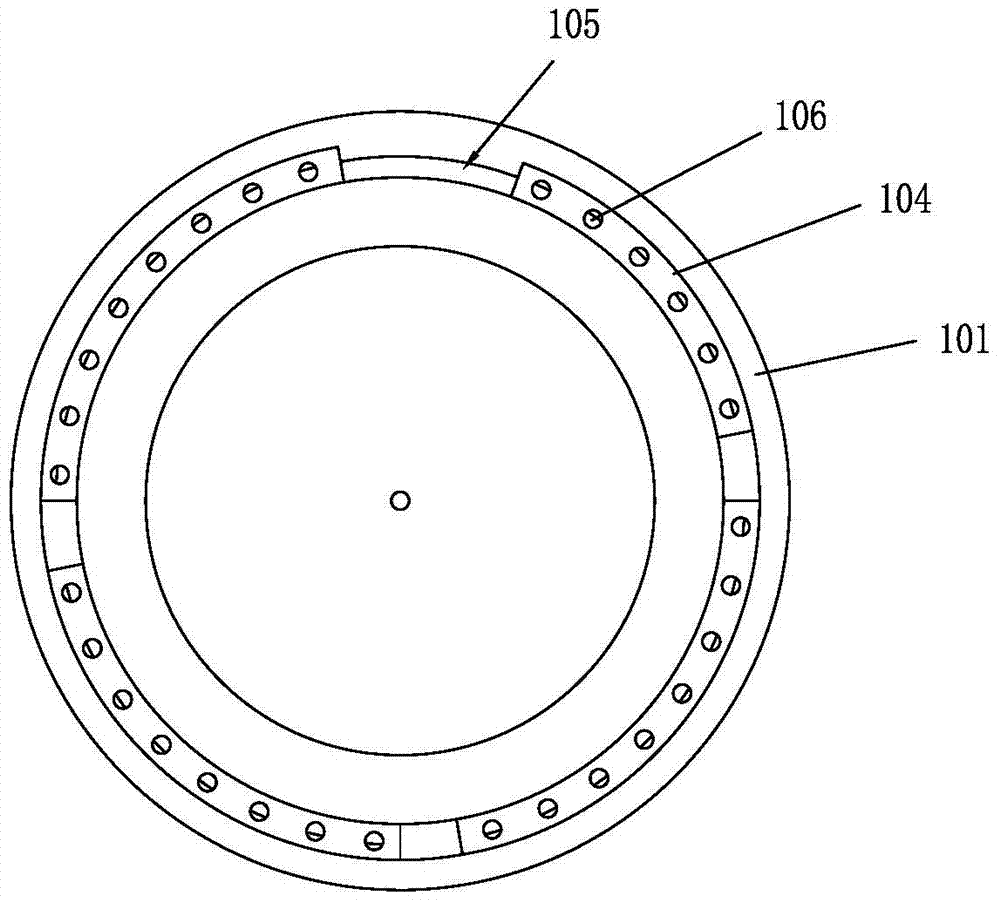

[0026] GTO device 1 such as figure 2 As shown, it is generally in the shape of a round cake, including a ceramic insulating shell 101. The anode 102 of the GTO device is in the middle of the top of the insulating shell 101 and serves as the anode of the IGTO device; the outer surface of the insulating shell 101 of the GTO device is provided with two The upper and lower ring structures are spaced apart, the last ring structure is the gate electrode ring 103 of the GTO device, and the next ring structure is the cathode ring 104 of the GTO device; figure 1 The marks 103 and 104 in the GTO are the gate and cathode of GTO; while the traditional GTO gate lead wire is a copper wire of 4 square ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com