Shell and manufacturing method thereof

A manufacturing method and housing technology, applied in the direction of telephone structure and other directions, can solve the problems of tolerance and gap in assembly, affecting user experience, and imperfection, so as to achieve the effect of improving experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

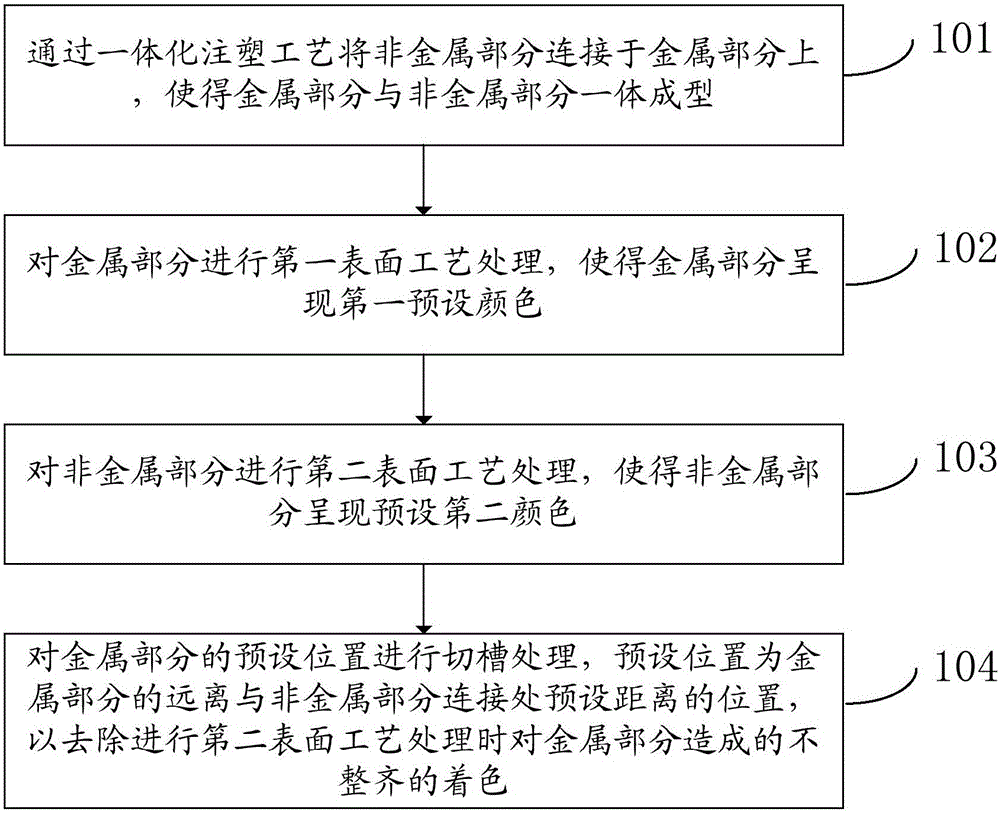

[0035] The invention discloses a method for manufacturing a housing, the following combination figure 1 An embodiment of the shell manufacturing method provided by the present invention is illustrated in detail.

[0036] In this embodiment, the housing includes metal parts and non-metal parts, and the manufacturing method of the housing includes:

[0037] 101. Connect the non-metal part to the metal part through an integrated injection molding process, so that the metal part and the non-metal part are integrally formed;

[0038] In order to ensure the quality of the mobile phone and prevent the mobile phone from being easily broken, most of the current mobile phone shell is made of metal. The signal of the mobile phone, so the position where the shell of the mobile phone is close to the input and output of the mobile phone signal cannot be made of metal. In order to prevent the loosening of the shell of the mobile phone caused by excessive use, at present, the shell of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com