Tea leaf processing equipment

A processing equipment and tea technology, which is applied in the field of tea processing equipment, can solve the problems of poor uniformity, low degree of automation, and difficulty in controlling the rolling force in the rolling process, and achieve high practical value, high degree of automation, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below, but the present invention can be implemented in various ways defined and covered by the claims, and the present invention will be described in detail below in conjunction with the accompanying drawings.

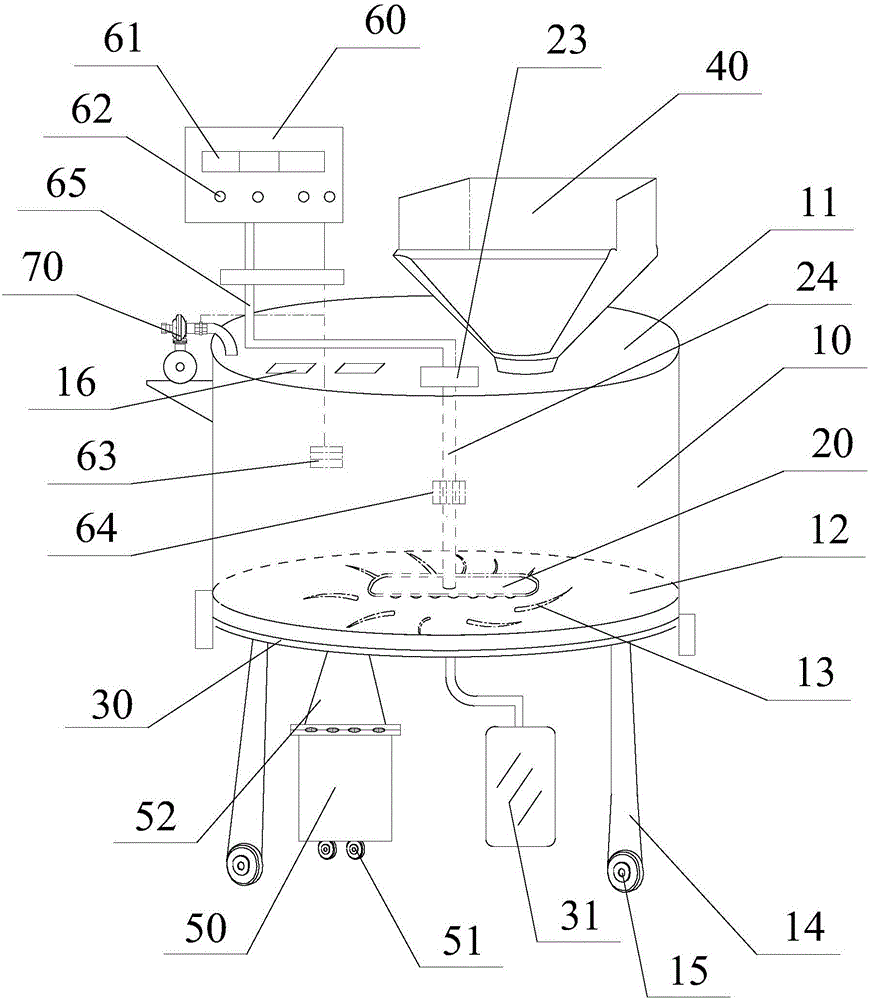

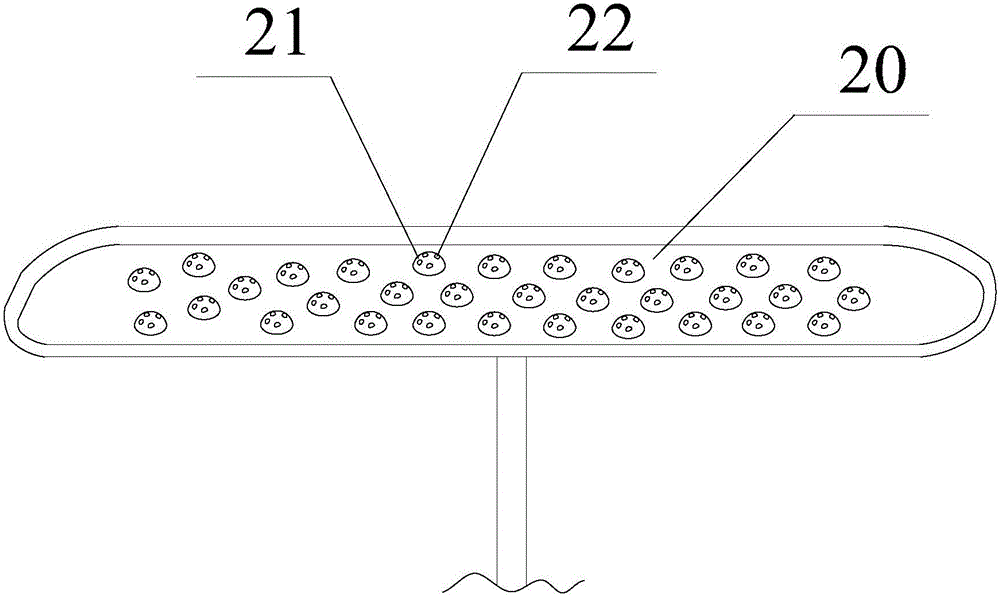

[0030] Such as figure 1 As shown, the present invention provides a kind of tea processing equipment, comprises frying tea pot 10, kneading device, heating device 30 and control module, and frying tea pot 10 is by the pot bottom 12 at the bottom, the upper cover plate 11 at the top and the The side shells form a closed accommodating chamber. The bottom of the pot 12 can be a planar structure, or it can be a curved surface with a certain radian downward along the horizontal direction, so that the tea leaves on the upper surface of the bottom of the pot 12 have a certain ability to gather centripetally, which is beneficial to concentrated rolling. The lower end of the bottom of the pot 12 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com