Vertical type hob tobacco cutter

A shredding machine and hob technology, which is applied in the processing of tobacco, tobacco, application, etc., can solve problems such as time-consuming, noise, and impact on shredded quality, so as to ensure the shredded quality, increase the adjustment range, and reduce the cutter roll The effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

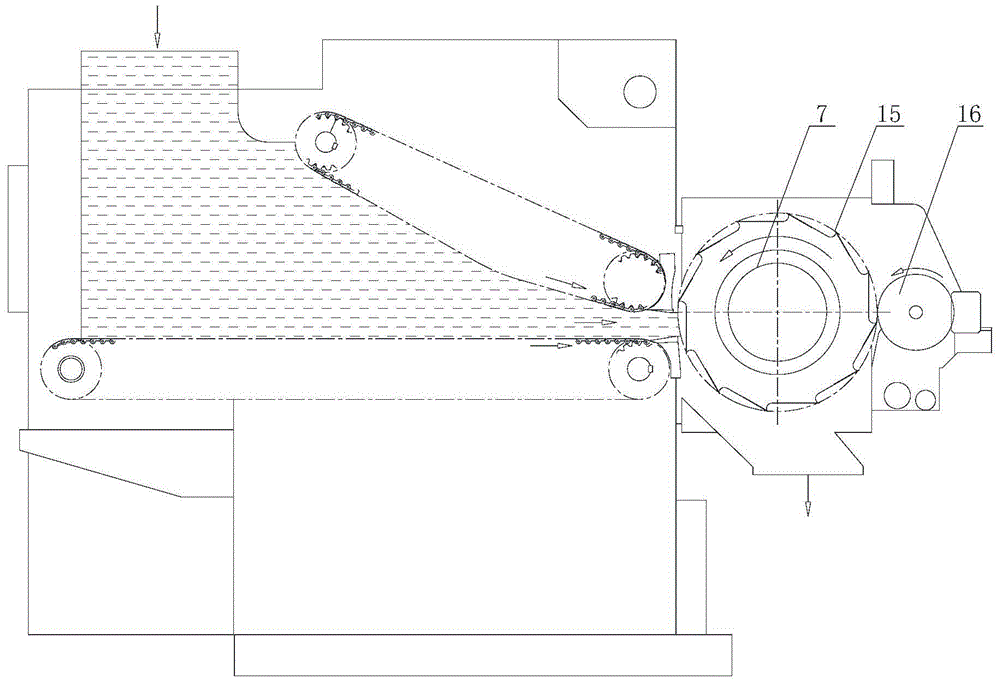

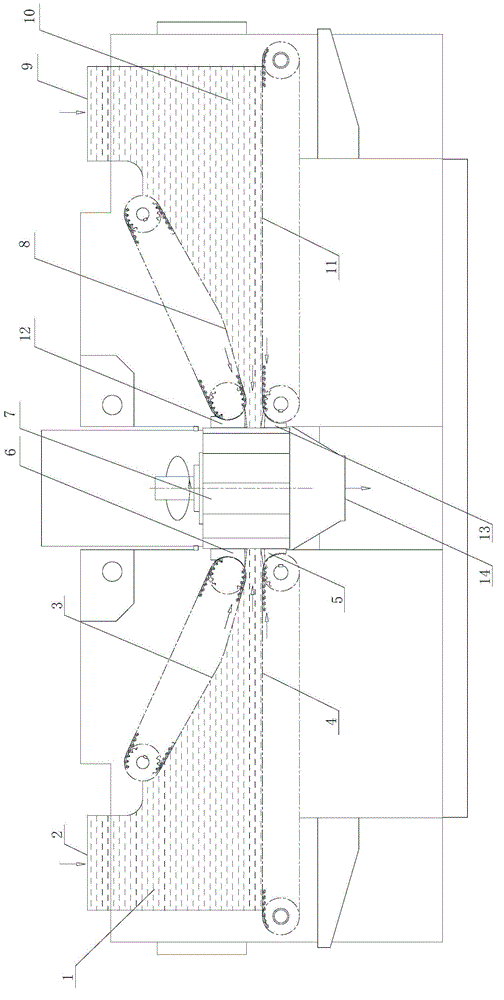

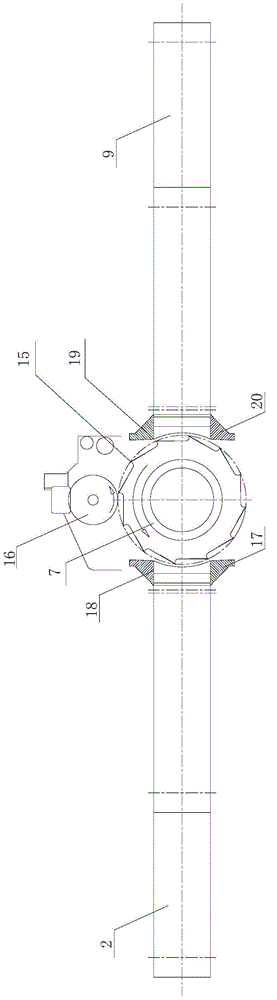

[0041] The feed bin of the shredder of the present embodiment comprises a first feed bin 1 and a second feed bin 10, and the first feed bin 1 and the second feed bin 10 are symmetrically arranged on both sides of the knife roller 7, so Described knife roller 7 vertical setting.

[0042] In this embodiment, the maximum material flow rates of the first feed bin 1 and the second feed bin 10 are approximately equal, and the flow rates of the first feed bin and the second feed bin each account for 1 / 2 of the total incoming material flow.

[0043] The first upper conveying chain 3 and the first lower conveying chain 4 are arranged in the first feeding bin 1 of this embodiment, and the upstream of the first upper conveying chain 3 and the first lower conveying chain 4 is provided with the first feeding Port 2, the first outlet is set downstream. The first outlet is arranged in a rectangle, and the upper and lower sides of the first outlet are respectively provided with the first upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com