Skeletal fixation device

A fixation device and fixation unit technology, applied in the direction of fixators, internal fixators, internal bone synthesis, etc., can solve the problems of being unable to adjust, stuck in the reaming part, and unable to be taken out, so as to enhance the support strength, increase the strength, and avoid scurrying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0151] Hereinafter, specific embodiments of the bone fixation device of the present invention will be described with reference to the drawings.

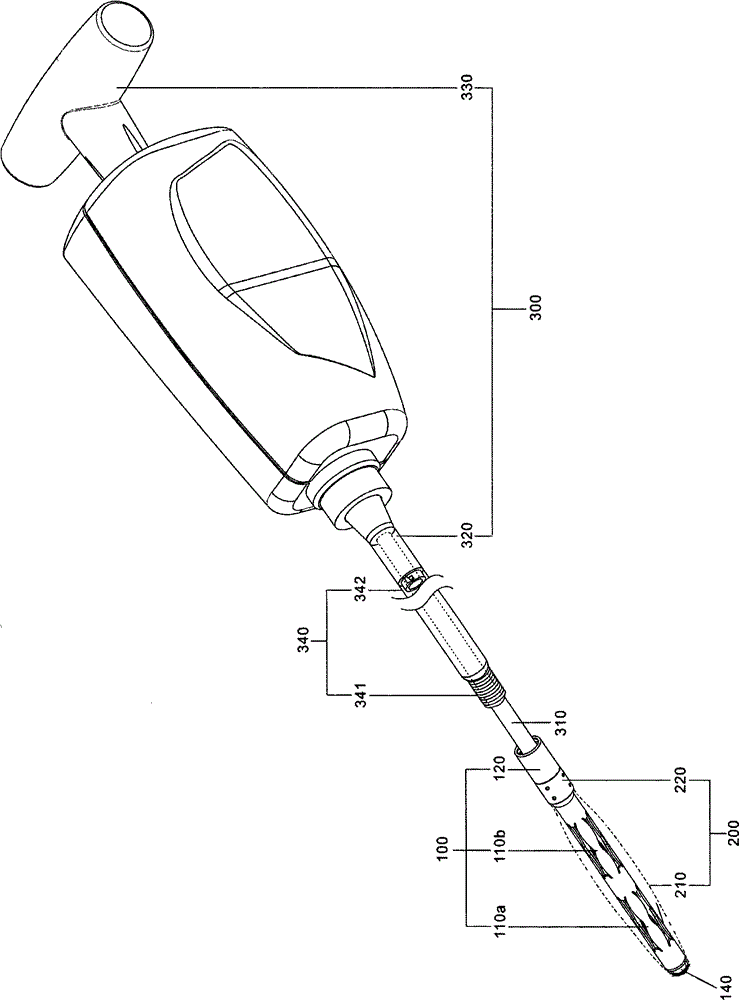

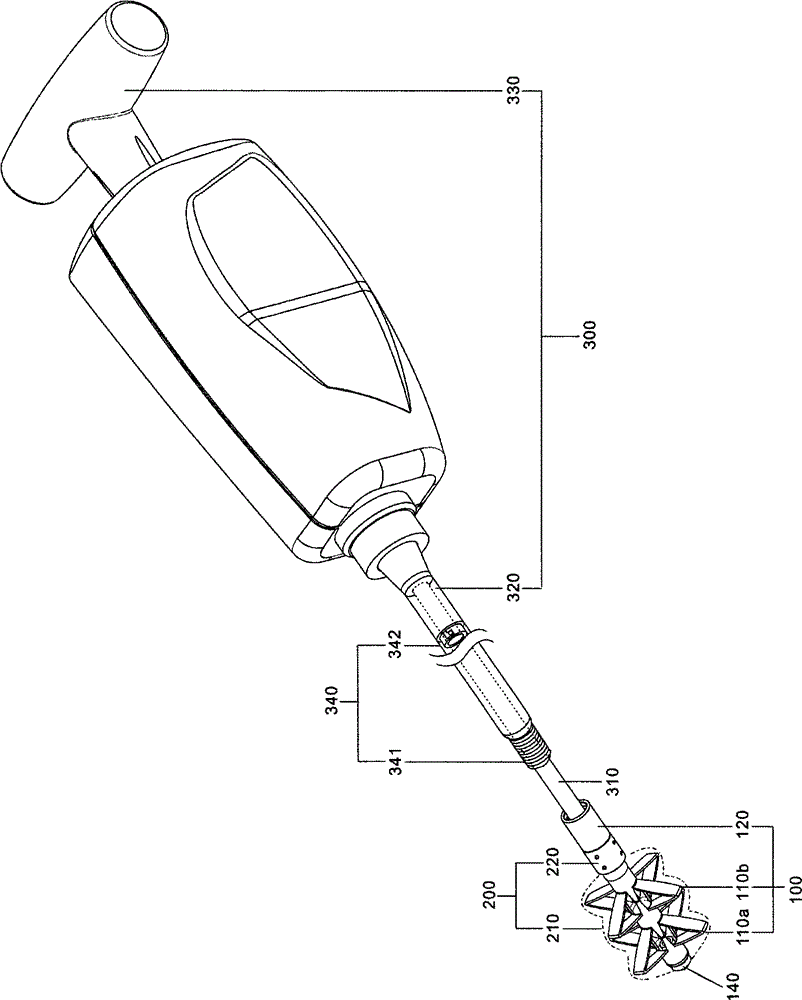

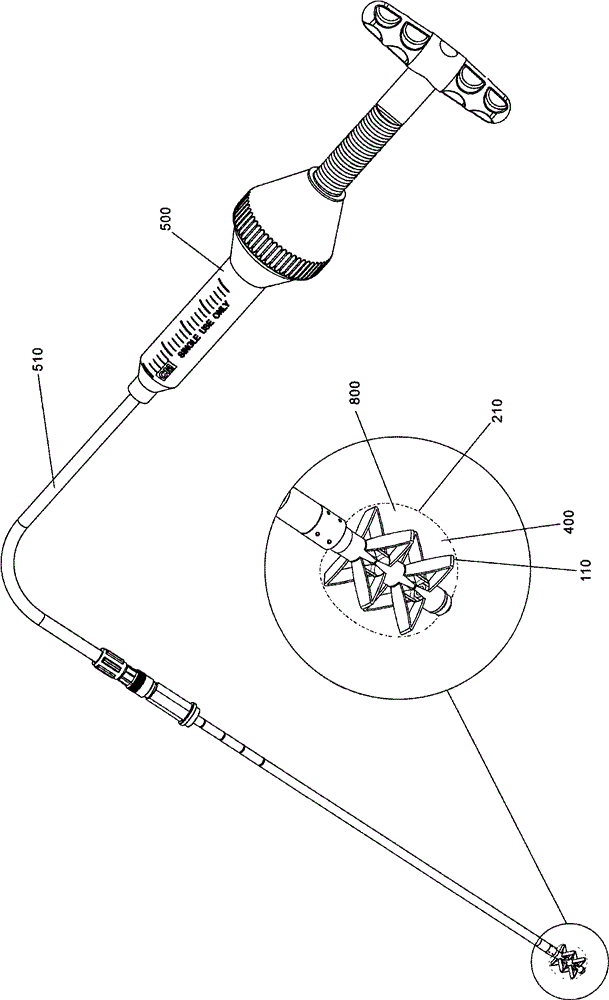

[0152] Figure 1a It is a schematic diagram of a preferred specific example of the bone fixation device of the present invention. Such as Figure 1a As shown, the expanded structure of the expanded unit 100 includes first expanded structures 110a and 110b, and the expanded structures 110a, 110b are in a contracted state. The covering unit 200 covers the deployment structures 110a, 110b of the deployment unit 100 by the spherical covering member 210, and also uses the covering unit 200 to block the broken bones in the vertebrae, so that the deployment unit 100 will not be affected by The bone fragments in the vertebrae get stuck, and it happens that the deployment unit 100 cannot be contracted to the collapsed state. The cladding unit 200 is fixedly connected with the deployment unit 100 by using the anchor at the connecting end 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com