Kitchen waste disposal device

A processing device and kitchen waste technology, which is applied in grain processing, mixer with rotating stirring device, grease/oily substance/floating matter removal device, etc. It can solve the problems of long processing process, bulky equipment, inconvenient household use, etc. , to achieve the effect of compact structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

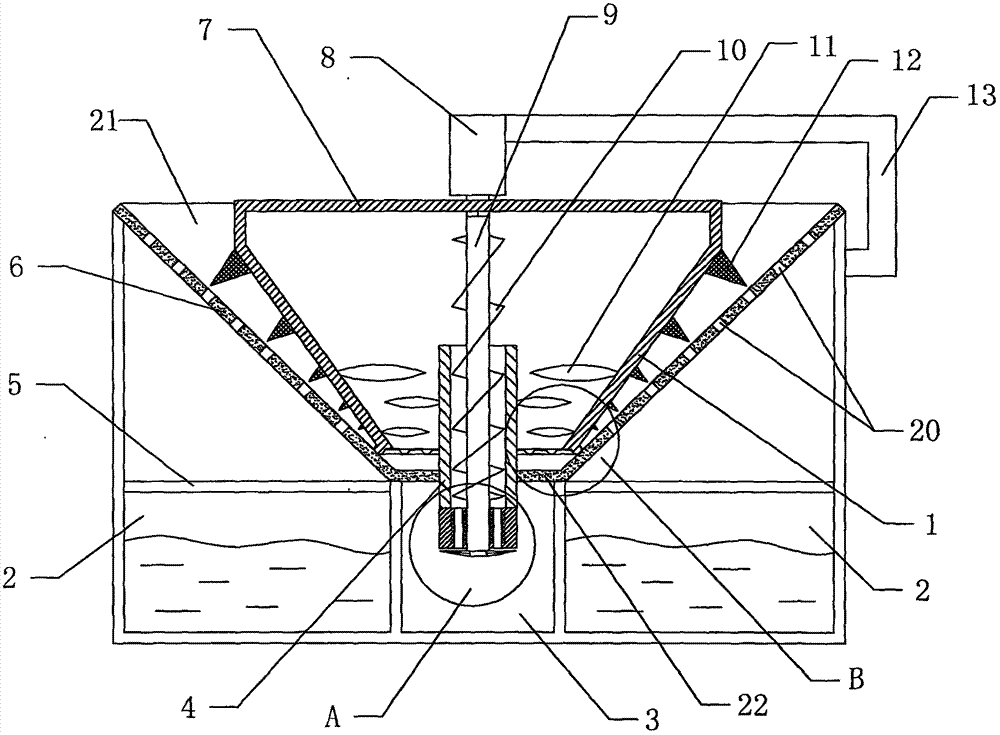

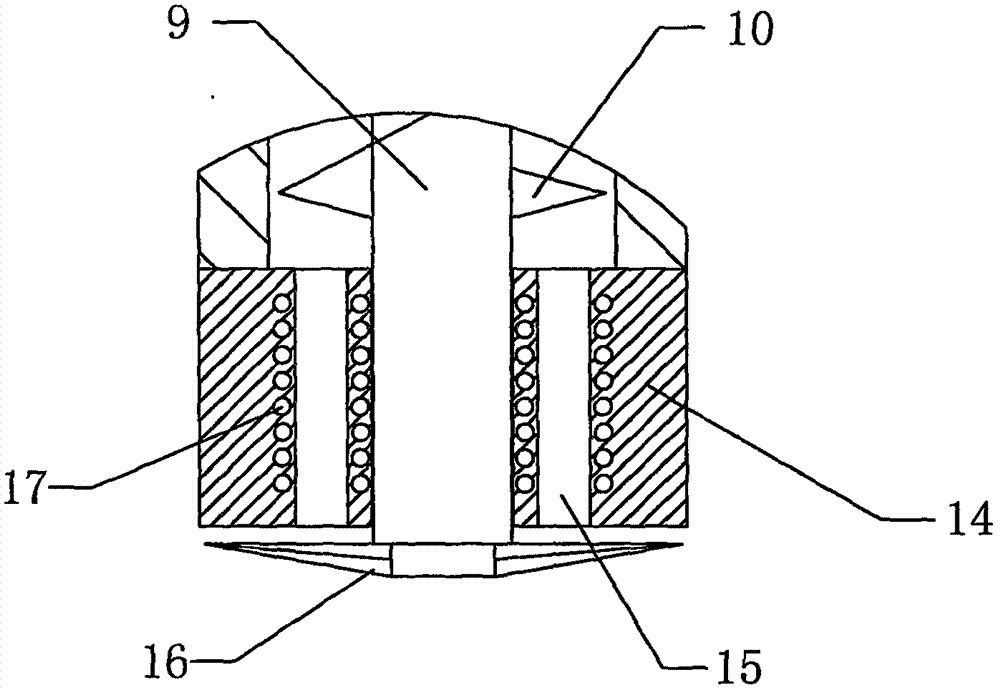

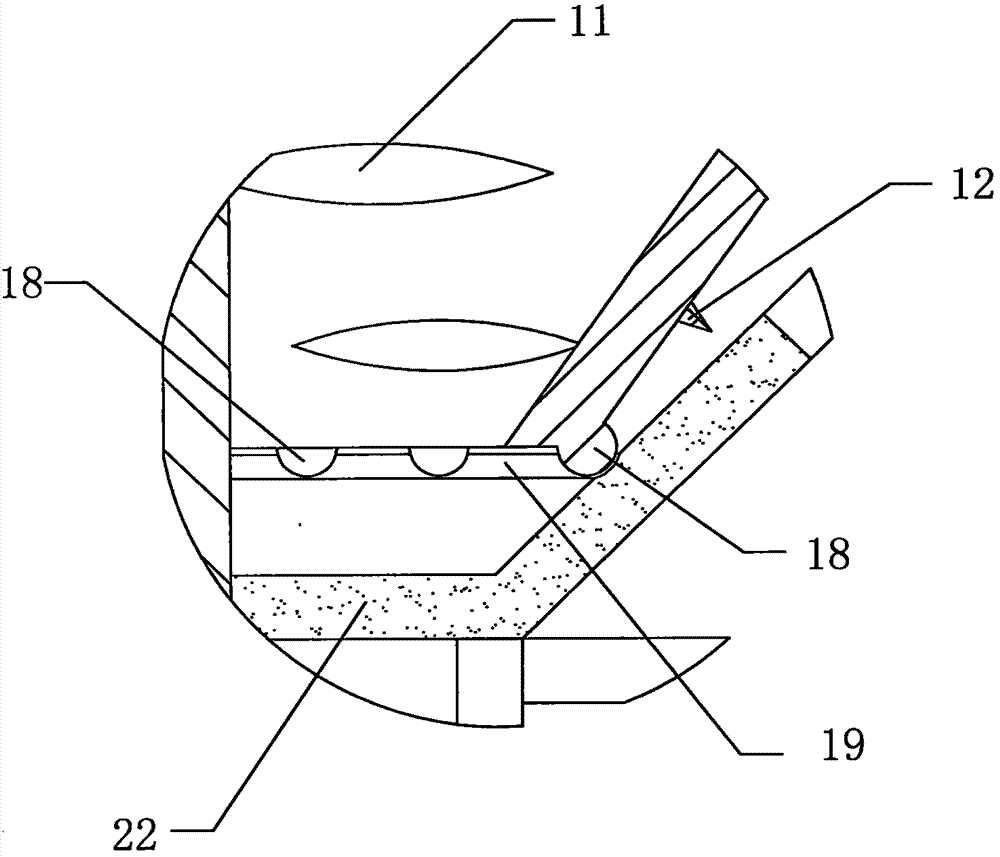

[0025] Such as figure 1 , 3 As shown, the kitchen waste treatment device includes an outer barrel 6, a feed port 21 is arranged above the outer barrel 6, an inner barrel 1 is arranged to rotate inside the outer barrel 6, and a plurality of spherical protrusions 18 are provided on the inner barrel 1. The outer barrel 6 is correspondingly provided with a groove 19, the inner barrel 1 is vertically arranged, the inner barrel 1 and the outer barrel 6 are conical, and the distance between the inner barrel 1 and the outer barrel 6 gradually decreases from top to bottom. Small, the inner barrel 1 is provided with a second spiral blade 12, the outer barrel 6 is provided with a number of water holes 20, the bottom of the inner barrel 1 is provided with an opening, and the bottom of the outer barrel 6 is provided with a baffle 22, The inner barrel 1 is provided with a stirring device and a discharging device. The water hole 20 communicates with the waste liquid tank 2, and the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com