Belt dragging skidding device

A belt and skid technology, which is applied in the field of belt dragging skid devices, can solve the problems of intermittent dragging process, wasteful replacement cost of the belt, bloated head part of the new belt, etc., and achieves simplified belt replacement operation steps and belt replacement steps. The effect of simplification and improved belt replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

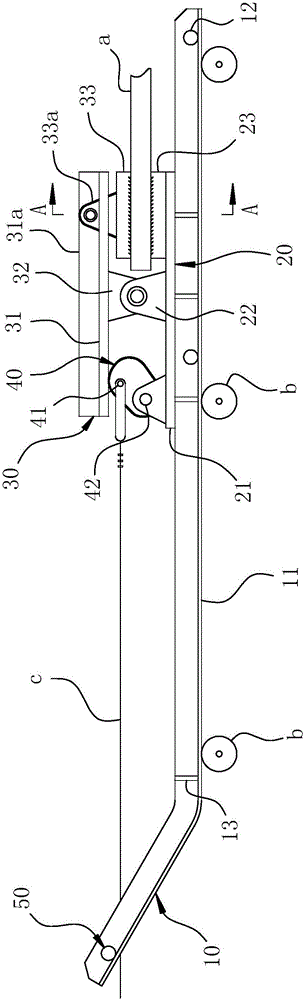

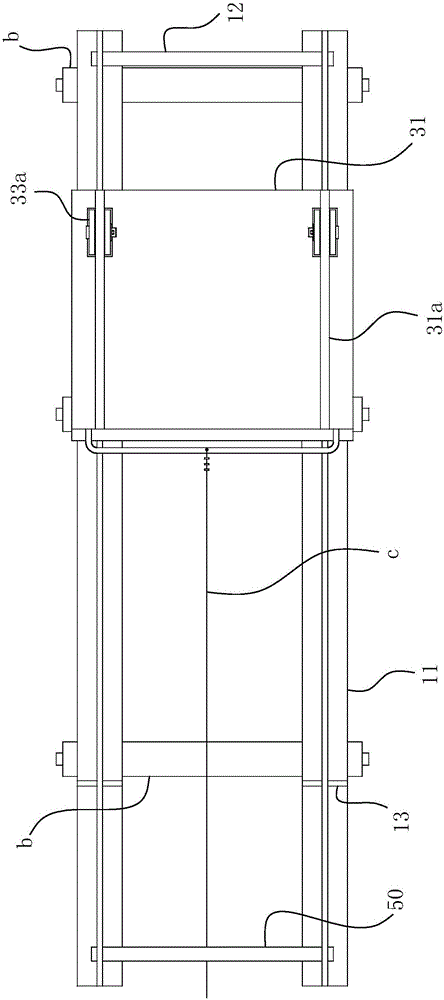

[0032] For ease of understanding, combined here Figure 1-3 The specific implementation structure and work flow of the present invention are described as follows:

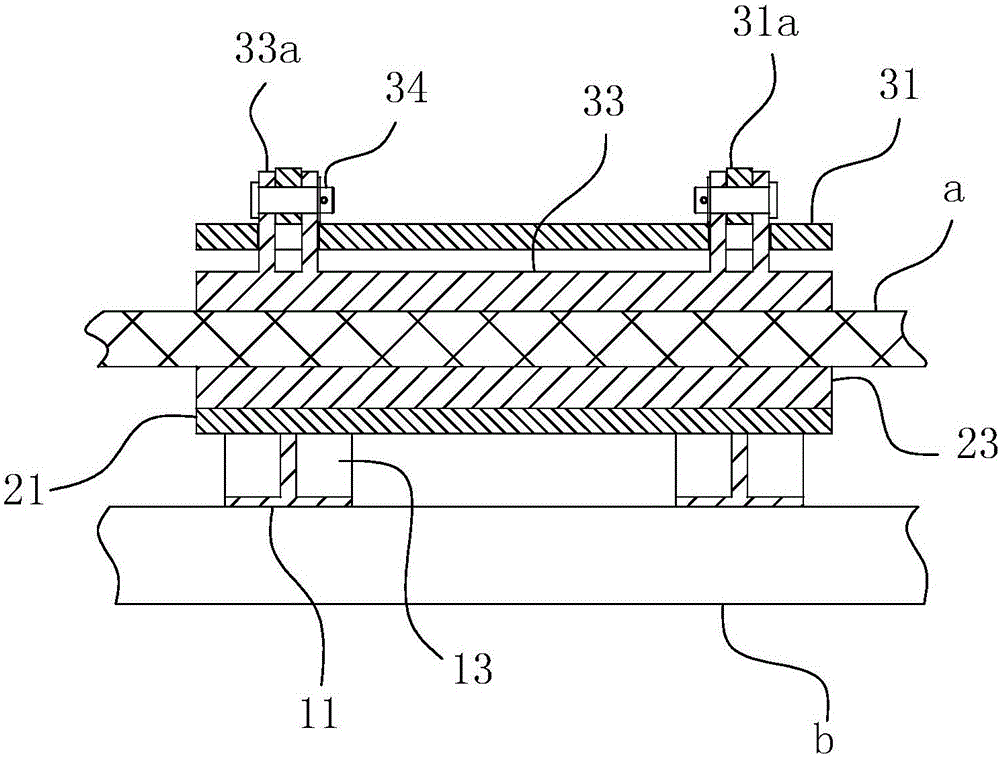

[0033] The invention as Figure 1-3 As shown, it includes: a movable jaw bracket 30 with a hinged part and a fixed jaw bracket 20, and the two brackets together form a jaw structure similar to a vise. The jaw is arranged on the underframe 10, so that it can slide on the idler rollers b of the belt conveyor along the laying path of the belt a by means of the underframe 10.

[0034]The movable jaw bracket 30 and the fixed jaw bracket 20 both include two plate bodies that constitute the movable jaw plate 31 and the fixed jaw plate 21 respectively, and the hinged ears 22 and the matching ears 32 protruding from the middle section between the two plate bodies constitute the above-mentioned vise occlusal structure. The fixed jaw plate 21 is directly welded on the underframe 10, and a fixed jaw block 23 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com