Magnetic coupling propulsion system and its application in ship propulsion

A technology of propulsion system and magnetic coupling, which is used in transmission devices with synchronous propulsion components, water action propulsion elements, etc., can solve the problems of ship net interference, large initial investment, increase in volume and weight of the propulsion system, and achieve vibration and noise. The effect of reducing, improving utilization, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

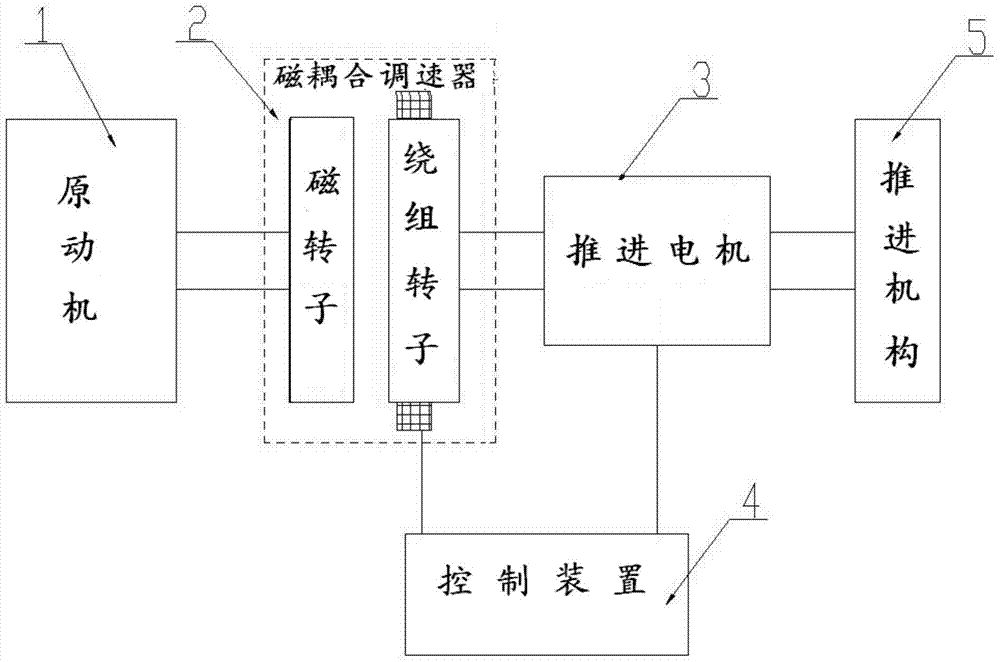

[0038] This embodiment provides a magnetic coupling propulsion system for ship propulsion, the structure is as follows figure 2 As shown, it includes a prime mover 1 , a magnetic coupling governor 2 , a propulsion motor 3 , a control device 4 and a propulsion mechanism 5 . Prime mover 1 is that the engine can be a fuel engine, a steam turbine or even an electric motor, and the original power system can be used. The prime mover here can run at a constant speed to make it work under the optimal working condition, with the highest combustion efficiency and energy Highest utilization rate. The magnetic coupling speed governor 2 includes a magnetic rotor and a winding rotor capable of mutual induction. The magnetic rotor and the winding rotor are arranged relative to each other without contact, and can induce mutual induction. The input shaft of the magnetic coupling speed governor 2 is connected to the magnetic rotor, and the output shaft is connected to the winding rotor. . Th...

Embodiment 2

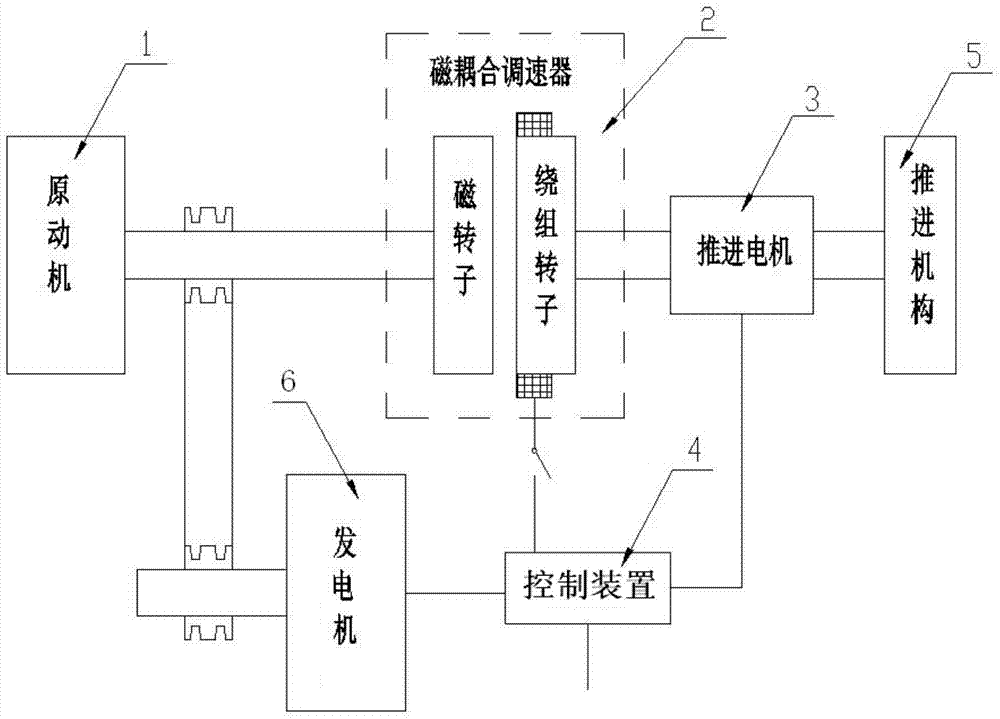

[0046] Another implementation is provided in this embodiment. When the capacity of the auxiliary propulsion motor is expanded, two propulsion mechanisms can be designed to serve as backups for each other or be divided into main and auxiliary propulsion mechanisms to work together. At this time, the structure of the magnetic coupling propulsion system of the ship is as follows:

[0047] The ship magnetic coupling propulsion system in this embodiment, such as image 3 As shown, it includes a prime mover 1 , a magnetic coupling governor 2 , a propulsion motor 3 , a control device 4 and a propulsion mechanism 5 . The prime mover 1 includes an engine and a speed reducer. The magnetic coupling governor 2 includes a magnetic rotor and a winding rotor capable of mutual induction, and the propulsion mechanism 5 includes a first propulsion mechanism 51 and a second propulsion mechanism 52, wherein

[0048] The output shaft of the prime mover 1 is connected with the input shaft of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com