A manufacturing method of bow-tie optical fiber preform with small stress zone for torsion

A technology of optical fiber preform and manufacturing method, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass production, etc., which can solve the problems of easy bursting, quartz volatilization and stacking, high ellipticity of fiber core, etc., so as to achieve not easy bursting and reduced optical fiber loss , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

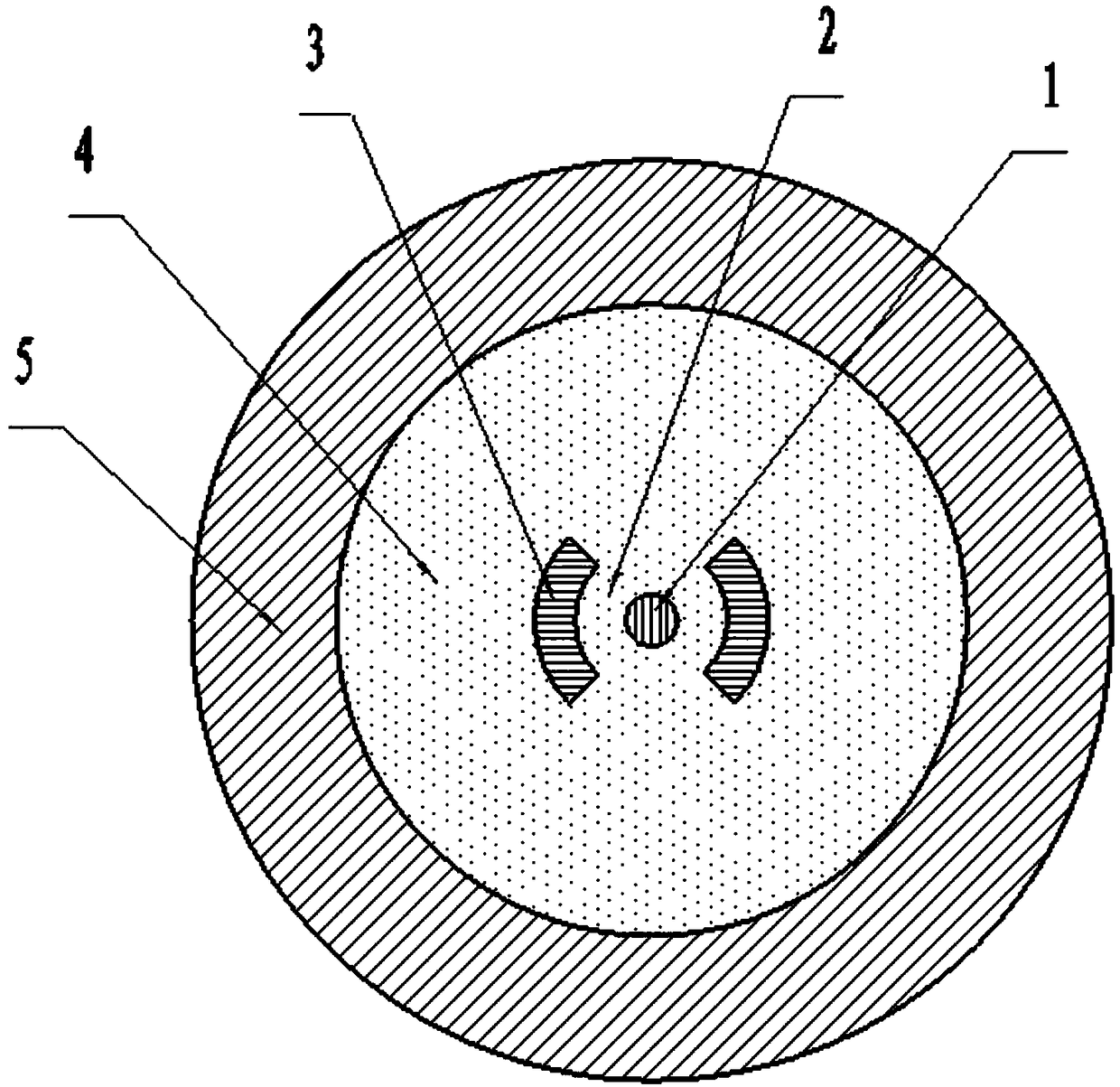

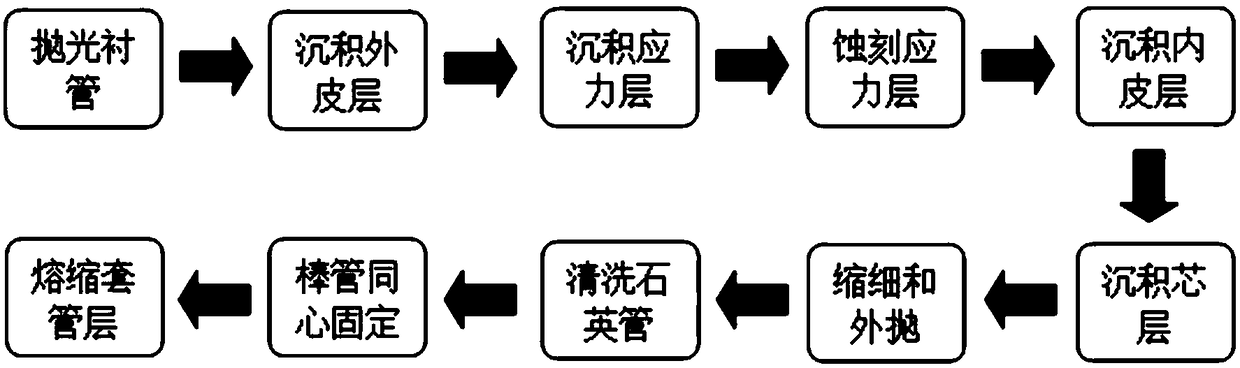

[0031] 1. In the rod making step, the feed volume of each layer of the stress layer is reduced by 20%, the number of deposition layers is 3, the feed volume of each layer of the inner skin layer is increased by 50%, and the number of deposition layers is 3 layers to make the outer diameter of the optical fiber preform 11.0mm, drawn into an optical fiber with a diameter of 79.8μm, the area of the stress zone is 241.3μm 2 , Accounting for 4.8% of the total area, this proportion can ensure that the preform will not burst under high temperature twisting or grinding and polishing at room temperature; the core ellipticity of the inner end of the fiber is 1.4%, and the core ellipticity of the outer end is 1.3%. Requirement before twisting: The optical fiber has a beat length of 6.67mm in the 1310nm band, which can meet the requirements for polarization performance before twisting.

[0032] 2. In the casing step, the outer diameter of the quartz rod is 19mm, the wall thickness is 2mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com